Advancing Precision: The Role of Hydraulic Pipe Fittings Machines in Modern Manufacturing

In the rapidly evolving landscape of industrial manufacturing, the demand for high-integrity, durable, and precise pipe fittings is paramount. These components form the backbone of fluid conveyance systems across virtually every major industry. Central to their production are advanced machinery solutions, and among the most critical is the hydraulic pipe fittings machine. This specialized equipment is engineered to perform a variety of critical operations, from bending and forming to flaring and end finishing, ensuring that pipe fittings meet stringent performance and safety standards. The industry is currently witnessing a significant trend towards greater automation and digitalization, driven by the need for enhanced efficiency, reduced labor costs, and superior product consistency. As supply chains become more complex and global quality benchmarks rise, the role of sophisticated hydraulic machinery in achieving these goals cannot be overstated. Manufacturers are increasingly investing in machines that offer higher precision, faster cycle times, and greater flexibility to adapt to diverse material specifications and design requirements.

The Meticulous Manufacturing Process of Advanced Pipe Fittings

The creation of high-quality pipe fittings involves a series of intricate manufacturing stages, each leveraging the power and precision of a hydraulic pipe fittings machine. The journey begins with the careful selection of raw materials, typically high-grade carbon steel, stainless steel (e.g., 304, 316L), or various alloy steels, chosen for their specific mechanical properties and corrosion resistance. The primary manufacturing processes include casting, where molten metal is poured into molds to create initial forms; forging, which involves shaping metal through localized compressive forces, enhancing grain structure and strength; and increasingly, advanced CNC (Computer Numerical Control) machining. CNC processes ensure unparalleled precision in dimensions and surface finish, crucial for leak-free connections. For instance, the creation of a complex elbow might involve initial forging for structural integrity, followed by hydraulic bending and subsequent CNC machining for exact beveling and threading. Throughout these stages, adherence to international inspection standards like ISO 9001, ANSI B16.9 (for wrought steel buttwelding fittings), and ASTM specifications is non-negotiable. These standards dictate material composition, dimensional tolerances, pressure ratings, and testing protocols. Properly manufactured fittings, often processed by a robust hydraulic pipe fittings machine, are designed for an extended service life, typically ranging from 20 to 50 years, depending on the material, application, and operating conditions, ensuring long-term reliability in critical infrastructure.

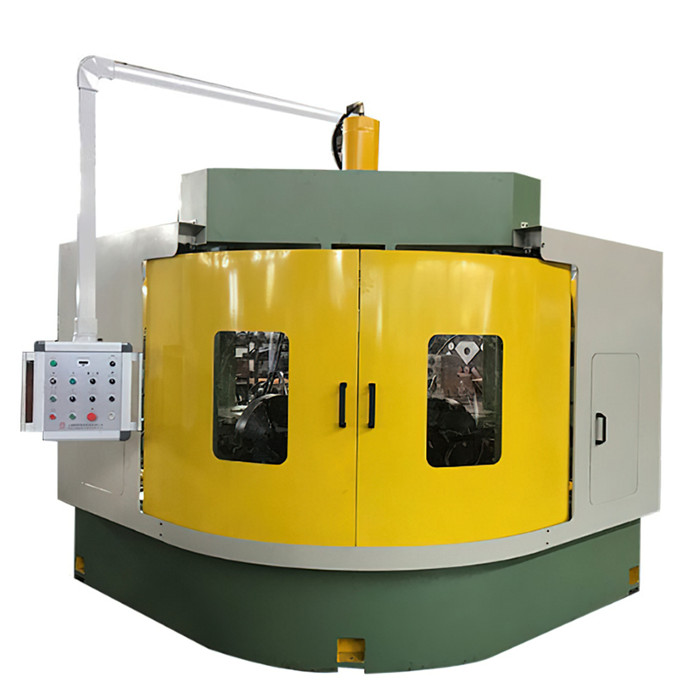

Key Technical Parameters and Performance of Hydraulic Pipe Fittings Machines

Understanding the technical specifications of a hydraulic pipe fittings machine is crucial for assessing its suitability for specific manufacturing demands. These machines are characterized by parameters such as maximum bending capacity (e.g., pipe diameter and wall thickness), hydraulic pressure, motor power, and control system sophistication. For instance, a typical machine designed for forming processes might feature a bending force of 150-300 tons, accommodating pipe diameters from DN15 to DN1000, with wall thicknesses up to 25mm. The hydraulic system's efficiency, often indicated by its energy consumption per cycle (e.g., 5-15 kWh), directly impacts operational costs. Control systems, frequently employing PLC (Programmable Logic Controller) with HMI (Human-Machine Interface), allow for precise programming of bending angles, forming sequences, and operational speeds. Advanced models may incorporate closed-loop feedback systems to compensate for material spring-back, ensuring consistent angles and dimensions. The structural rigidity and vibration dampening capabilities are also vital, contributing to the machine's longevity and the precision of the output. These machines are engineered for continuous operation, with robust designs that minimize downtime and maintenance requirements, ensuring high throughput for demanding production environments.

Typical Hydraulic Pipe Fittings Machine Specifications

| Parameter | Value Range | Unit |

|---|---|---|

| Max Forming Pressure | 150 - 600 | Tons |

| Pipe Diameter Range | DN15 - DN1200 (NPS 1/2" - 48") | mm / inches |

| Max Wall Thickness | 3 - 35 | mm |

| Motor Power | 22 - 75 | kW |

| Control System | PLC with HMI | |

| Machine Dimensions (Approx.) | 5m x 2.5m x 2m | L x W x H |

Diverse Application Scenarios and Industry Impact

The versatility of the hydraulic pipe fittings machine makes it indispensable across a multitude of industries where reliable fluid and gas conveyance is critical. In the petrochemical and oil & gas sectors, these machines produce fittings capable of withstanding extreme pressures, corrosive media, and high temperatures, vital for drilling, refining, and transportation pipelines. For example, fittings for subsea pipelines often require specialized cold forming capabilities to maintain material integrity. The metallurgy industry relies on these machines for processing various metal alloys into intricate shapes for structural and functional applications. In the water supply and drainage sector, robust, corrosion-resistant fittings are crucial for municipal infrastructure, requiring precise bending and flaring to ensure long-term leak prevention. Beyond these, sectors like shipbuilding, power generation, automotive, and construction also heavily depend on these machines for producing tailored pipe components. A notable example is the tee forming machine, a specialized variant that efficiently produces seamless tees, critical for diverting flow in piping systems, ensuring minimal pressure drop and maximum flow efficiency. These machines contribute significantly to energy saving through precision manufacturing that reduces material waste and to superior corrosion resistance by handling advanced alloys and ensuring optimal surface finishes that prevent degradation. The ability of a hydraulic pipe fittings machine to deliver highly uniform products contributes directly to the operational efficiency and safety of large-scale industrial systems.

Technological Advantages and Innovation in Hydraulic Pipe Fittings Production

Modern hydraulic pipe fittings machine designs integrate several technological advancements that offer significant advantages to manufacturers. High-precision hydraulic cylinders, often equipped with proportional valves, allow for exceptionally fine control over forming forces and speeds, leading to highly accurate and repeatable results. This level of control minimizes material distortion and ensures uniform wall thickness, which is critical for maintaining structural integrity under pressure. Advanced automation features, including robotic loading/unloading and automated tool changes, drastically reduce cycle times and enhance overall productivity, while also improving worker safety by minimizing manual handling. The integration of sophisticated sensors provides real-time feedback on parameters such as pressure, temperature, and material flow, enabling proactive adjustments and predictive maintenance. Furthermore, the robust construction of these machines, using high-tensile steel frames and precision-ground components, ensures exceptional stability and minimizes vibrations during operation, contributing to a longer machine lifespan and consistent product quality. These innovations collectively translate into lower operational costs, reduced material waste, and the production of higher-quality fittings that surpass previous industry benchmarks, offering a competitive edge to businesses investing in such technology.

Manufacturer Comparison and Tailored Custom Solutions

Choosing the right hydraulic pipe fittings machine vendor requires a thorough evaluation beyond just initial cost. Key factors include the manufacturer's reputation for engineering excellence, the reliability of their hydraulic systems, the availability of comprehensive after-sales support, and their capacity for customization. Leading manufacturers often have decades of experience, offering a range of standard models, but their true value lies in their ability to provide tailored solutions. For example, specific projects might require machines capable of handling unusually large diameters or exotic alloys, demanding bespoke tooling and programming. Manufacturers that excel in this area can design and build machines optimized for unique material properties, complex geometric requirements, or integration into existing automated production lines. A company with a strong track record, evidenced by long-term partnerships with industry leaders and a significant service history (e.g., over 15 years in operation), typically demonstrates higher trustworthiness. Moreover, the availability of detailed technical documentation, training programs for operators, and rapid spare parts supply are crucial considerations for ensuring continuous, efficient operation. Partnering with a manufacturer who understands the nuances of your specific production challenges can lead to substantial long-term savings and improved product quality.

Real-World Application Cases & Customer Experiences

The tangible benefits of utilizing advanced hydraulic pipe fittings machine technology are best illustrated through real-world applications and customer feedback. For instance, a major oil and gas pipeline contractor reported a 30% reduction in production time for large-diameter pipe elbows after implementing a new, high-tonnage hydraulic bending machine, coupled with an improvement in dimensional accuracy by over 15% compared to their previous methods. This efficiency gain translated directly into significant project cost savings and accelerated delivery schedules. Another example comes from a prominent shipbuilding yard that adopted a specialized hydraulic forming machine for custom manifold production. The machine's ability to precisely form complex shapes from marine-grade alloys, minimizing welding requirements, led to enhanced structural integrity and reduced labor costs. Customers frequently highlight the reliability of these machines, often citing operational uptimes exceeding 98% in demanding 24/7 environments. Feedback consistently emphasizes the user-friendly HMI interfaces, which shorten operator training times, and the robust construction that withstands years of heavy-duty use. These success stories underscore the critical role of a well-engineered hydraulic pipe fittings machine in achieving operational excellence and delivering superior components that meet the rigorous demands of global industries.

Ensuring Quality and Reliability: Standards & Certifications

The integrity of pipe fittings produced by a hydraulic pipe fittings machine is validated through strict adherence to internationally recognized quality standards and certifications. ISO 9001 certification is fundamental, demonstrating a commitment to quality management systems throughout the manufacturing process, from raw material procurement to final product inspection. Beyond this, specific industry standards are crucial: for example, API (American Petroleum Institute) specifications for oil and gas components, ASME (American Society of Mechanical Engineers) codes for pressure vessels and piping, and relevant ASTM (American Society for Testing and Materials) material specifications. Each batch of fittings often undergoes rigorous testing, including hydrostatic testing to verify leak resistance, ultrasonic testing for internal flaws, radiographic inspection for welding integrity, and destructive tests like tensile and impact testing to confirm mechanical properties. Reputable manufacturers will also provide Material Test Certificates (MTCs) that document the chemical composition and mechanical properties of the materials used, directly traceable to the raw material supplier. These certifications and testing protocols ensure that every fitting produced by a hydraulic pipe fittings machine meets the highest benchmarks for safety, performance, and durability, instilling confidence in critical applications.

Frequently Asked Questions (FAQ) about Hydraulic Pipe Fittings Machines

- Q: What types of materials can a hydraulic pipe fittings machine process?

A: These machines are highly versatile and can process a wide range of materials, including carbon steel, stainless steel (e.g., 304, 316L), duplex and super duplex stainless steels, various alloy steels, copper, brass, and aluminum. The specific material capabilities depend on the machine's tonnage, tooling, and design. - Q: How does a hydraulic pipe fittings machine ensure precision?

A: Precision is achieved through several integrated technologies: high-accuracy hydraulic cylinders with proportional valves for fine control, advanced PLC-based control systems for exact programming of movements, robust machine frames for minimal deflection, and often, laser or optical sensing for real-time dimension verification. - Q: What is the typical service life and maintenance requirement for these machines?

A: With proper maintenance, a high-quality hydraulic pipe fittings machine can have a service life of 15-25 years or more. Regular maintenance typically involves checking hydraulic fluid levels, filter replacement, lubrication of moving parts, and periodic inspection of seals and electrical components, usually on a quarterly or semi-annual basis. - Q: Can these machines be integrated into an automated production line?

A: Absolutely. Modern hydraulic pipe fittings machines are designed with automation in mind. They often feature interfaces compatible with robotic loading/unloading systems, conveyor belts, and central manufacturing execution systems (MES), enabling seamless integration into fully automated production lines to maximize efficiency and throughput.

Delivery, Warranty, and Comprehensive Customer Support

For B2B clients, the post-purchase experience is as critical as the product itself. Reputable manufacturers of hydraulic pipe fittings machine understand this, offering streamlined delivery processes, clear warranty commitments, and robust customer support. Standard delivery times for custom-built machinery typically range from 12 to 24 weeks, depending on complexity and current production schedules, with expedited options often available. A standard warranty period usually covers 12 to 24 months from installation or commissioning, guaranteeing against manufacturing defects and major component failures. Beyond the warranty, comprehensive customer support includes access to skilled technicians for troubleshooting, remote diagnostics capabilities, and the prompt availability of genuine spare parts to minimize operational downtime. Many providers offer service contracts that include preventative maintenance visits, operator training programs, and software updates to ensure the machine continues to operate at peak performance throughout its lifespan. This commitment to ongoing support is vital for protecting client investments and ensuring long-term operational efficiency and reliability of the hydraulic pipe fittings machine.

Conclusion and Future Outlook

The hydraulic pipe fittings machine stands as a cornerstone in modern industrial fabrication, driving precision, efficiency, and reliability in fluid conveyance systems worldwide. As industries continue to evolve, demanding even higher performance from critical components, the innovation within this machinery sector will remain vibrant. Future developments are likely to focus on enhanced integration with Industry 4.0 technologies, including advanced AI for predictive maintenance, even more precise real-time adaptive controls, and greater customization through modular designs. The emphasis on sustainable manufacturing will also drive improvements in energy efficiency and waste reduction throughout the forming process. Investing in a state-of-the-art hydraulic pipe fittings machine is not merely an equipment purchase; it is a strategic decision that directly impacts product quality, operational efficiency, and competitive advantage in a demanding global market. For businesses committed to excellence and long-term sustainability, these machines represent the indispensable tools for future success.

References

- American Society of Mechanical Engineers (ASME). ASME B16.9, Factory-Made Wrought Buttwelding Fittings.

- International Organization for Standardization (ISO). ISO 9001:2015, Quality management systems — Requirements.

- American Petroleum Institute (API). API 5L, Specification for Line Pipe.

- ASTM International. Standard Specifications for Various Steel Pipe and Fitting Materials.

Post time: Aug . 11, 2025 13:40