Understanding API 5CT Casing and Tubing Pipes

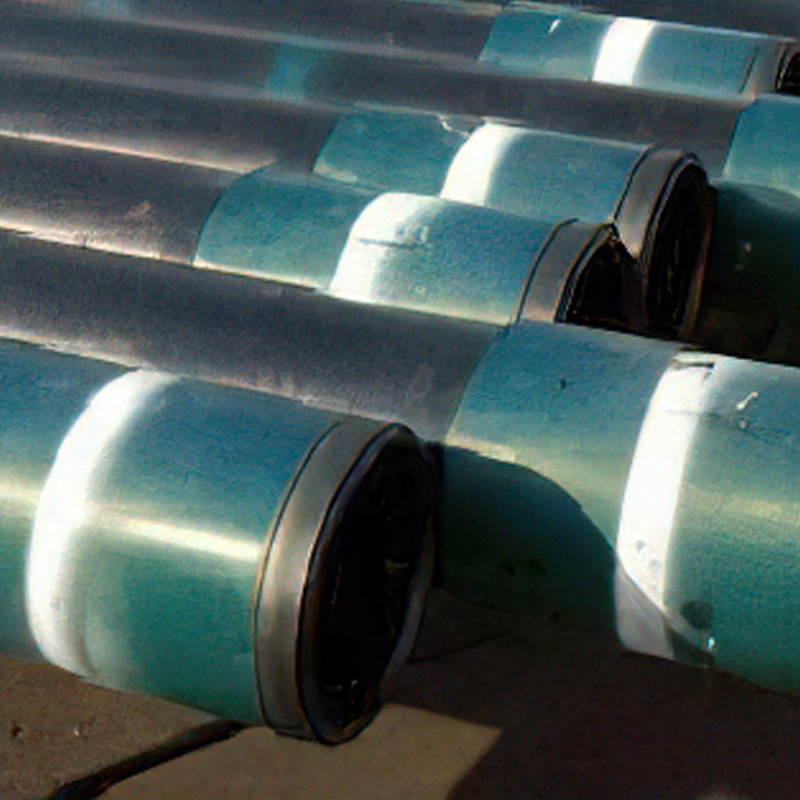

In the demanding sectors of oil, gas, and geothermal exploration, the integrity of a wellbore is paramount. This integrity is primarily ensured by the robust construction and reliable performance of well casing pipe for sale. These specialized pipes, crucial for stabilizing boreholes and isolating production zones, must adhere to stringent industry standards to withstand extreme pressures, temperatures, and corrosive environments. The global energy landscape is witnessing a heightened demand for high-performance casing and tubing, driven by increasingly complex drilling operations, deeper wells, and the exploitation of unconventional resources. This trend necessitates not only superior material science but also advanced manufacturing processes to ensure maximum operational safety and efficiency. Understanding the technical specifications, application nuances, and manufacturing excellence behind these products is vital for informed procurement decisions in the B2B sphere.

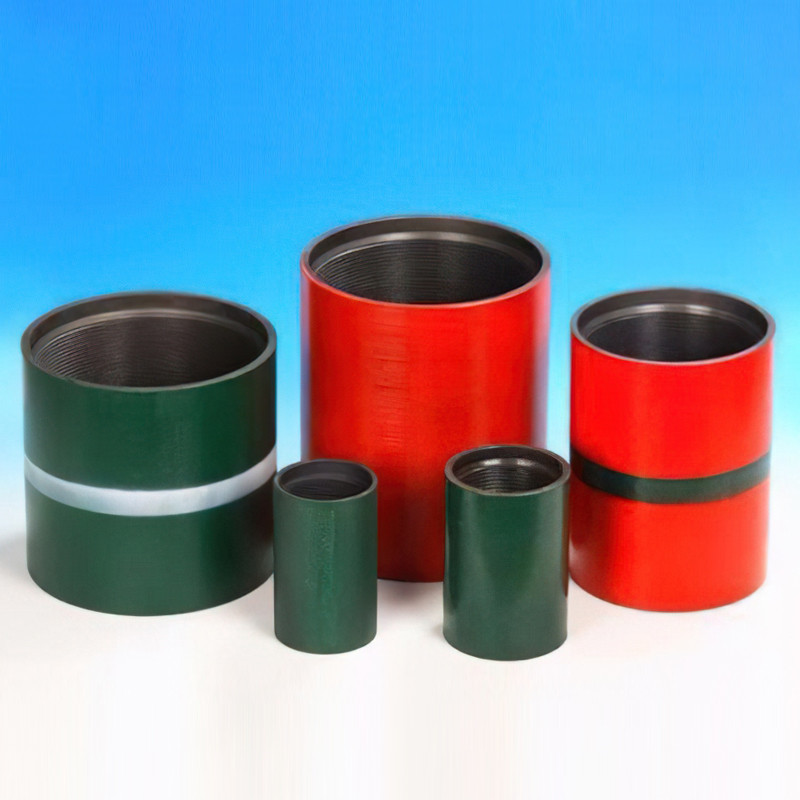

API 5CT is the definitive standard governing seamless and welded casing and tubing for the petroleum and natural gas industries. It specifies the technical delivery conditions for steel pipes, couplings, and pup joints, ensuring consistency and reliability across the supply chain. Different grades, such as J55, K55, N80, and L80, offer varying levels of yield strength and tensile strength, making them suitable for diverse well conditions. The Buttress Thread Connection (BTC), a common threading type, provides high tensile strength and gas-tight sealing, crucial for deep and high-pressure wells. Selecting the correct grade and connection is critical for well integrity, preventing collapse, burst, and connection failure under operational stresses.

Technical Parameters of API 5CT Casing and Tubing Pipe

When evaluating options for well casing pipe for sale, precise technical specifications are paramount. Our API 5CT L80/N80/J55/K55 BTC Casing and Tubing Pipes are engineered to meet the rigorous demands of various downhole applications. Key parameters include pipe diameter (OD), wall thickness, steel grade, connection type, and lengths. These elements collectively determine the pipe's performance characteristics, such as collapse resistance, internal yield pressure, and tensile strength, all of which are critical for wellbore integrity and operational safety. For instance, a higher grade like L80 offers superior resistance to sour gas environments compared to J55, making it suitable for wells with high H2S concentrations. The dimensions of casing pipe are typically specified by outer diameter and weight per foot, which correlates directly with wall thickness.

Below is a table illustrating typical specifications for API 5CT casing pipes, providing a quick reference for common dimensions and their corresponding properties. This data aids engineers and procurement specialists in identifying the most suitable products for their specific project requirements, whether it's standard casing pipe for borewell applications or specialized deep-well operations requiring enhanced material properties. For example, a common size like `5 1/2 casing pipe for sale` will have specific weight and performance ratings critical for its intended depth and pressure.

| API Grade | OD (inches) | Wall Thickness (inches) | Weight (lb/ft) | Min. Yield Strength (psi) | Min. Tensile Strength (psi) |

|---|---|---|---|---|---|

| J55 | 5.5 | 0.244 - 0.361 | 15.5 - 23 | 55,000 | 75,000 |

| K55 | 7 | 0.276 - 0.453 | 23 - 32 | 55,000 | 95,000 |

| N80 | 7 | 0.317 - 0.514 | 26 - 38 | 80,000 | 100,000 |

| L80 | 9.625 | 0.352 - 0.545 | 36 - 53.5 | 80,000 | 95,000 |

The Manufacturing Process: Precision and Quality Assurance

The production of high-grade casing pipe involves a sophisticated series of stages, ensuring that each pipe meets rigorous international standards. The journey begins with the selection of premium-grade steel billets, typically sourced from reputable mills compliant with ISO 9001 quality management systems. These billets undergo precise heating and seamless rolling, often via mandrel mills, to form the basic pipe body. This hot rolling process is followed by careful cooling, straightening, and cutting to specified lengths. For specific applications requiring enhanced properties, pipes may undergo specialized heat treatments, such as quenching and tempering, to achieve the desired yield strength and toughness, characteristic of grades like L80 or N80.

Subsequent stages involve the critical machining of connections, such as the BTC (Buttress Thread Connection), using advanced CNC (Computer Numerical Control) equipment to ensure precise threading and optimal seal integrity. Each pipe then undergoes extensive non-destructive testing (NDT), including eddy current, ultrasonic, and magnetic particle inspection, to detect any internal or surface flaws. Hydrostatic testing is also performed to verify the pipe's ability to withstand internal pressure. These rigorous inspection standards, typically aligning with API 5CT and ASTM/ANSI specifications, guarantee product reliability and a long service life. Our commitment to these processes ensures that every API 5CT L80/N80/J55/K55 BTC Casing and Tubing Pipe destined for casing pipe for sale meets and often exceeds client expectations for performance and durability in sectors like petrochemical, metallurgy, and water supply/drainage, significantly contributing to anti-corrosion and energy-saving initiatives in their respective applications.

Applications and Technical Advantages of Casing Pipe

The versatility and robust design of API 5CT casing pipe make it indispensable across a spectrum of industries beyond conventional oil and gas. In the energy sector, it serves as the foundational structure for oil and gas wells, providing mechanical support and isolating various formations. For geothermal energy projects, specialized casing is required to manage high temperatures and corrosive geothermal fluids. The use of casing pipe for borewell applications in water supply and irrigation is also extensive, ensuring clean water delivery and preventing contamination. Moreover, these pipes find utility in structural applications, such as foundation piling and mine support, where high strength and durability are critical.

The technical advantages of our well casing pipe for sale are manifold. Superior material composition and heat treatment processes contribute to exceptional corrosion resistance, extending the operational life even in harsh downhole environments. The precise BTC threading ensures a secure, leak-proof connection, critical for maintaining well pressure and preventing environmental contamination. High yield and tensile strengths allow these pipes to withstand immense axial loads and internal pressures, reducing the risk of collapse or burst. Furthermore, the longevity and reduced maintenance requirements of high-quality casing pipes lead to significant long-term cost savings, aligning with energy-efficient operational goals and minimizing environmental impact through reduced material consumption and fewer interventions. Our products, including specific dimensions like `5 1/2 casing pipe for sale`, are designed for peak performance and reliability.

Custom Solutions and Manufacturer Reliability

In the specialized realm of casing pipe for sale, standard products might not always suffice for unique project specifications. We excel in providing custom solutions, tailoring pipe dimensions, steel grades, connection types, and protective coatings to precise client needs. Whether it's a specific OD, a non-standard length, or a unique thread design, our engineering team collaborates closely with clients to deliver optimized pipe solutions that enhance operational efficiency and longevity. This bespoke approach ensures that even the most challenging drilling projects have access to the exact wellbore integrity solutions they require, minimizing risks and maximizing returns. Our extensive experience in the field, serving clients globally for over 15 years, underpins our capability to handle complex orders efficiently and reliably.

Choosing a reliable manufacturer for well casing pipe for sale is critical. Our commitment to excellence is validated by stringent certifications, including ISO 9001 for quality management and API Q1, affirming our adherence to the highest standards in the petroleum and natural gas industry. We maintain robust partnerships with leading global logistics providers, ensuring timely and secure delivery of products to any location. Our established track record of successful projects, spanning across diverse geological conditions and operational demands, stands as a testament to our product quality and service reliability. We invite prospective clients to review our service cases and engage with our team to discuss how our expertise in API 5CT L80/N80/J55/K55 BTC Casing and Tubing Pipe can directly benefit their upcoming ventures.

Frequently Asked Questions (FAQ) and Customer Support

Navigating the complexities of casing pipe procurement can raise several questions. Here are some frequently asked questions to provide clarity and instill confidence in our offerings. Our dedicated customer support team is always available to provide detailed answers and technical assistance.

-

Q: What is the typical delivery timeframe for your well casing pipe for sale?

A: Delivery times vary based on order volume, customization requirements, and destination. Generally, standard orders are dispatched within 4-6 weeks, with expedited options available for urgent requirements. We provide a detailed delivery schedule upon order confirmation. -

Q: Do you offer a warranty on your casing pipe products?

A: Yes, all our API 5CT L80/N80/J55/K55 BTC Casing and Tubing Pipes come with a comprehensive quality assurance warranty, covering manufacturing defects and material integrity. Specific terms are detailed in our sales agreements. -

Q: How do you ensure the quality of casing pipe for borewell applications?

A: Beyond API and ISO certifications, each batch undergoes strict internal quality control, including chemical composition analysis, mechanical property testing, and non-destructive examination, ensuring suitability for various borewell conditions.

Our customer support is designed to be responsive and technically proficient. From initial inquiry to post-delivery assistance, our team is committed to providing seamless service. We understand that acquiring the right casing pipe for sale involves significant investment and technical considerations, and we are dedicated to supporting our clients at every step. This commitment extends to providing detailed technical documentation, material test reports, and after-sales support to ensure optimal product performance throughout its lifespan.

Conclusion: Your Trusted Partner for Casing Pipe Solutions

In conclusion, the selection of API 5CT L80/N80/J55/K55 BTC Casing and Tubing Pipe is a critical decision influencing the safety, efficiency, and longevity of any wellbore project. Our comprehensive range of products, backed by advanced manufacturing processes, stringent quality control, and extensive industry expertise, positions us as a leading supplier for well casing pipe for sale. We are committed to delivering not just pipes, but complete solutions tailored to the unique demands of each client, whether for complex deep-well drilling or standard casing pipe for borewell applications. Our focus on technical excellence, transparent communication, and unwavering support ensures that you receive superior products that meet global standards and exceed your operational expectations. Partner with us to secure the structural integrity and operational success of your critical projects.

References

- American Petroleum Institute. (2020). API Specification 5CT: Specification for Casing and Tubing. 10th Edition.

- ASTM International. (2021). ASTM A53/A53M: Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless.

- ISO (International Organization for Standardization). (2015). ISO 9001: Quality Management Systems – Requirements.

- Cormack, D. E. (2007). Oil and Gas Production Handbook: An Introduction to Oil and Gas Production. 2nd Edition.

- Baker Hughes. (2023). Well Construction and Drilling Technology Overview. Internal Publication.

Post time: Aug . 12, 2025 04:40