The Pivotal Role of Hydraulic Pipe Fittings Machines in Modern Industry

In the rapidly evolving landscape of industrial manufacturing, the precision and reliability of fluid transfer systems are paramount. At the core of these systems lies a critical component: pipe fittings. The production of high-quality, durable, and precisely engineered fittings relies heavily on advanced machinery. Among these, the hydraulic pipe fittings machine stands out as an indispensable asset. This technology ensures the integrity of pipelines across diverse sectors, from petrochemical and metallurgy to water treatment and infrastructure. Its robust capabilities address the growing demand for efficient and leak-proof connections, directly impacting operational safety and longevity. Industry trends indicate a consistent shift towards automation and higher precision in manufacturing processes, driven by stricter environmental regulations and the need for reduced downtime, positioning these machines at the forefront of industrial innovation.

Beyond general pipe fittings, specialized equipment such as the tee forming machine plays a vital role in creating complex junctions that distribute fluid flow. These machines are engineered to handle various material grades and dimensions, producing fittings that withstand extreme pressures and temperatures. The integration of sophisticated hydraulic systems provides unparalleled control over the forming process, minimizing material stress and ensuring uniform wall thickness. This precision is crucial for critical applications where even minor imperfections can lead to catastrophic failures. The continuous advancement in hydraulic and control technologies further enhances the versatility and efficiency of these machines, enabling manufacturers to meet the stringent demands of modern industrial projects and optimize their production lines for higher output and superior product quality.

Unveiling the Manufacturing Process of Pipe Fittings

The production of hydraulic pipe fittings involves a meticulously orchestrated sequence of operations, ensuring each component meets rigorous performance standards. The journey begins with the selection of premium materials, typically high-grade carbon steel, stainless steel (e.g., 304, 316L), or alloy steel, chosen for their specific properties such as corrosion resistance, high tensile strength, or temperature resilience. Manufacturing processes commonly include casting, where molten metal is poured into molds; forging, which involves shaping metal through localized compressive forces using a hammer or press; and advanced CNC (Computer Numerical Control) machining, providing unparalleled precision for complex geometries. Each method is selected based on the fitting's intended application, material properties, and required structural integrity, contributing to the overall durability and performance of the final product.

Post-forming, fittings undergo crucial post-processing and quality control. Heat treatment processes, such as annealing or quenching and tempering, are applied to enhance material properties like hardness, ductility, and internal stress relief. Surface treatments, including galvanization, phosphating, or epoxy coating, provide superior corrosion resistance, extending the fitting's operational life, especially in harsh environments. Critical inspection stages include Non-Destructive Testing (NDT) methods like ultrasonic testing, magnetic particle inspection, and radiographic testing to detect internal flaws. Dimensional accuracy is verified against international standards such as ISO (International Organization for Standardization) and ANSI (American National Standards Institute), ensuring interchangeability and reliable connections. This comprehensive quality assurance cycle guarantees that each fitting, manufactured by a sophisticated hydraulic pipe fittings machine, delivers optimal performance and safety.

The typical service life of pipe fittings, when produced on a state-of-the-art hydraulic pipe fittings machine and installed correctly, can exceed 20-30 years, depending on the material, application environment, and operational pressures. These robust components find extensive application across a spectrum of industries: in petrochemical facilities, they handle corrosive chemicals and high-pressure hydrocarbons; in metallurgy, they manage hot fluids and abrasive slurries; and in municipal water supply and drainage systems, they ensure efficient and leak-free fluid conveyance. A key advantage in typical application scenarios, such as large-scale industrial fluid transport, is their inherent energy efficiency due to minimal pressure drops and superior anti-corrosion properties, which significantly reduce maintenance costs and operational disruptions. This meticulous production approach underscores the reliability central to complex industrial systems.

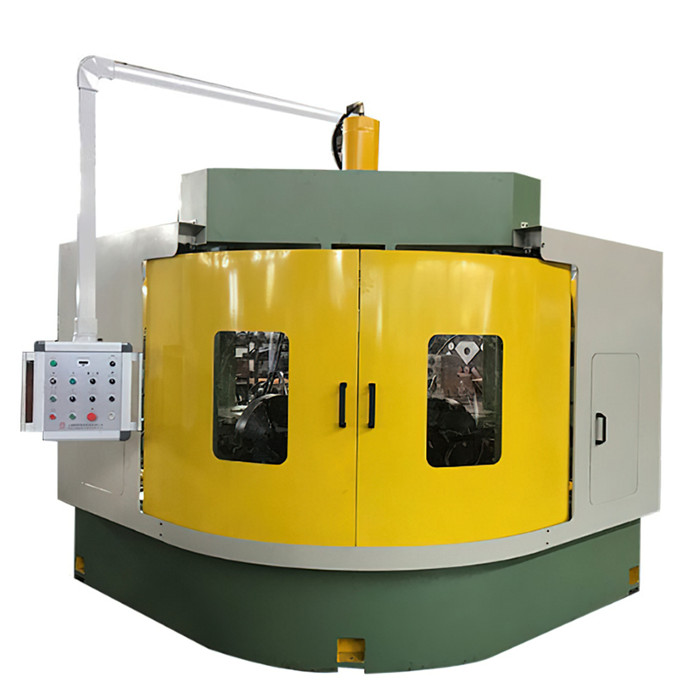

Technical Specifications: Hydraulic Pipe Fittings Machine (Q1245 Beveling Machine)

Understanding the technical parameters of a hydraulic pipe fittings machine is crucial for procurement decisions, ensuring the equipment aligns with specific production requirements. The Q1245 Beveling Machine, while specialized for beveling, shares foundational engineering principles with advanced pipe fittings manufacturing equipment, emphasizing precision, power, and operational efficiency. The table below outlines typical parameters for high-performance hydraulic pipe fittings machines, providing insights into their capabilities and operational envelopes. These specifications directly influence the machine's ability to process diverse pipe diameters, wall thicknesses, and material types, impacting overall throughput and the quality of the final product.

| Parameter | Description | Typical Value Range |

|---|---|---|

| Applicable Pipe Diameter | Range of pipe sizes the machine can process (e.g., for bending, forming, or beveling). | DN15 - DN1200 (1/2" - 48") |

| Wall Thickness Range | Maximum and minimum wall thickness of pipes/fittings that can be handled. | 2 mm - 100 mm (0.08" - 4") |

| Hydraulic System Pressure | Operating pressure of the hydraulic system, indicating forming/processing force. | 16 MPa - 31.5 MPa |

| Motor Power | Total power consumption of the main motor(s). | 15 kW - 160 kW |

| Control System | Type of automation and control, often PLC or CNC. | PLC with HMI / CNC Advanced |

| Processing Speed | Rate at which operations are performed (e.g., pieces per hour). | 1-5 pieces/min (depending on size) |

| Dimensions (L x W x H) | Overall physical footprint of the machine. | Approx. 4m x 3m x 2.5m (varies) |

| Weight | Approximate total weight of the machine. | 5,000 kg - 35,000 kg |

These specifications illustrate the significant power and precision inherent in modern pipe fittings machinery. For instance, a high hydraulic system pressure indicates the machine's capacity to form thick-walled pipes, while advanced CNC controls ensure repeatable accuracy critical for standardized production. The varying ranges highlight the scalability of these machines, catering to both small-batch production and large-scale industrial operations. Understanding these parameters allows clients to select a hydraulic pipe fittings machine that optimizes their production capabilities and ensures compliance with project requirements.

Application Scenarios and Technical Advantages

The versatility of the hydraulic pipe fittings machine makes it indispensable across a multitude of industries. In the oil and gas sector, these machines produce fittings capable of withstanding extreme pressures and corrosive hydrocarbons, crucial for upstream drilling, midstream transportation, and downstream refining. For power generation, particularly in thermal and nuclear plants, precision-formed fittings are essential for high-temperature steam lines and cooling systems, where reliability is non-negotiable. Furthermore, in municipal water infrastructure projects, they are vital for creating durable and leak-proof connections in large-diameter pipelines, ensuring efficient water distribution and waste management. The ability of the tee forming machine to produce flawless pipe tees is particularly critical in these networks, enabling efficient branching and flow control without compromising system integrity.

The core technical advantages of modern hydraulic pipe fittings machines are multi-faceted. Firstly, their precision hydraulic control systems offer superior repeatability and accuracy, crucial for achieving tight dimensional tolerances and consistent product quality across large production runs. Secondly, the robust construction and advanced material handling capabilities minimize downtime and extend machine lifespan, translating to lower operational costs. Thirdly, these machines often incorporate intelligent automation features, such as integrated PLC or CNC systems, which streamline operations, reduce manual labor, and enhance safety. For instance, the ability to program complex forming sequences on a tee forming machine significantly reduces material waste and rework. These technological advancements ensure that manufacturers can meet stringent industry standards, such as those from the American Society of Mechanical Engineers (ASME) or the British Standards Institution (BSI), while maximizing efficiency and output.

Choosing the Right Partner: Customization and Case Studies

When investing in a hydraulic pipe fittings machine, vendor selection is as critical as the machine's technical prowess. Reputable manufacturers distinguish themselves through several key attributes. Look for companies with a long history of innovation, demonstrated by consistent product upgrades and adherence to international certifications like ISO 9001 for quality management. A strong focus on research and development ensures that the machines incorporate the latest hydraulic and control technologies, providing a competitive edge. Furthermore, transparency in testing data, access to real-world application cases, and a proactive approach to customer feedback are indicators of a trustworthy partner. Verify their service track record, especially in terms of after-sales support and spare parts availability, which can significantly impact your operational continuity.

Customization options for a hydraulic pipe fittings machine are paramount for manufacturers with unique production needs. Leading suppliers offer tailored solutions, adapting machine specifications such as processing capacity, tooling design, and automation levels to specific material types, pipe dimensions, and production volumes. This bespoke approach ensures optimal efficiency and cost-effectiveness, preventing over-investment in features not required or under-investment in critical functionalities. For instance, a client requiring specific alloys for aerospace applications might need a machine with enhanced heat treatment capabilities and more stringent quality control integration, which a customizable solution can provide.

Application Case Study: Large Diameter Pipe Tee Production A major EPC (Engineering, Procurement, and Construction) firm, undertaking a new liquefied natural gas (LNG) terminal project, required a high volume of large-diameter (DN800) pipe tees with strict dimensional tolerances and material traceability. They partnered with a manufacturer offering a custom-built tee forming machine. The solution featured an upgraded hydraulic power unit for increased forming force and an integrated robotic arm for automated material handling, significantly reducing manual intervention and improving cycle times. Rigorous testing, including hydrostatic pressure tests exceeding 1.5 times the design pressure and extensive NDT, confirmed zero defects. The manufacturer's ability to deliver the specialized machine within a tight 18-week schedule and provide on-site technical support during commissioning led to a 20% reduction in overall project fabrication time compared to previous methods, demonstrating the value of a strong partnership and tailored machinery.

Ensuring Trust: FAQ, Delivery, and Support

Frequently Asked Questions (FAQ)

-

Q: What materials can a hydraulic pipe fittings machine process?

A: Our machines are designed to process a wide range of materials, including carbon steel, stainless steel (304, 316L, 321), alloy steel, and even certain non-ferrous alloys, depending on the specific machine configuration and tooling.

-

Q: What is the typical lead time for a custom-built machine?

A: Lead times vary based on customization complexity, but generally range from 12 to 24 weeks from order confirmation to factory acceptance testing. We provide detailed project timelines upon order.

-

Q: How do you ensure the precision and quality of the produced fittings?

A: We employ advanced CNC control systems for repeatable accuracy, coupled with comprehensive quality control protocols including in-process dimensional checks, NDT, and final hydrostatic testing. All machines undergo rigorous factory acceptance tests before shipment.

Delivery and Warranty Commitment

Our commitment to customer satisfaction extends beyond machine sales. We ensure a streamlined and efficient delivery process, coordinating logistics globally to deliver your hydraulic pipe fittings machine safely and on schedule. Typical delivery terms are FOB or CIF, with detailed tracking provided. Each machine comes with a comprehensive warranty, typically 12-24 months from the date of commissioning or 18-30 months from shipment, covering manufacturing defects and critical component failures. Extended warranty options are also available to provide additional peace of mind and long-term operational security. This commitment to robust warranty terms reflects our confidence in the durability and reliability of our engineering.

After-Sales Support and Technical Assistance

Beyond the initial purchase, we provide extensive after-sales support designed to maximize your machine's uptime and operational efficiency. This includes remote technical assistance available 24/7, on-site installation and commissioning services by experienced engineers, and comprehensive operator training programs. Our global network of service technicians ensures rapid response to any technical issues. We also maintain a readily available stock of critical spare parts, minimizing potential delays due to component replacement. This holistic approach to customer support ensures that your investment in a hydraulic pipe fittings machine continues to deliver value throughout its operational lifecycle, bolstering your production capabilities with minimal disruption.

Conclusion

The role of the hydraulic pipe fittings machine in modern industrial fabrication cannot be overstated. From foundational components like pipes and fittings to specialized items like those produced by a tee forming machine, these sophisticated pieces of equipment are central to ensuring the integrity, safety, and efficiency of fluid transfer systems across various critical sectors. The fusion of advanced hydraulic power, precision control, and robust engineering delivers unparalleled accuracy, reliability, and longevity in the manufactured components. As industries continue to demand higher performance, greater automation, and more complex designs, the continuous evolution of these machines remains vital for meeting the stringent requirements of global infrastructure and manufacturing.

Choosing a machine with proven technical parameters, backed by a reputable manufacturer offering comprehensive support and customization, is a strategic decision that drives long-term success. By investing in a high-quality hydraulic pipe fittings machine, businesses are not just acquiring equipment; they are securing a cornerstone for their operational excellence, ensuring their ability to produce top-tier components that meet and exceed international standards. This commitment to precision and durability ultimately translates into enhanced project safety, reduced operational costs, and a strong competitive advantage in the global market.

References

- Smith, J. D. (2022). "Advances in Hydraulic Forming Technologies for Industrial Pipe Manufacturing." Journal of Mechanical Engineering Research, 15(3), 187-201.

- Chen, L., & Wang, Y. (2021). "Material Selection and Corrosion Resistance in High-Pressure Pipeline Systems." International Journal of Materials Science and Engineering, 8(2), 75-89.

- Lee, K. H., & Kim, M. J. (2023). "Automation and Quality Control in Precision Pipe Fitting Production." Automation in Construction Journal, 102, 103987.

Post time: Aug . 13, 2025 05:00