Understanding the Apex of Precision: Hydraulic Pipe Fittings Machine Technology

In the intricate world of industrial fluid transfer systems, the integrity and performance of pipe fittings are paramount. These components, ranging from elbows and tees to reducers and caps, are the linchpins ensuring leak-proof, efficient, and durable pipeline networks across diverse sectors. At the heart of manufacturing these critical elements lies advanced machinery designed for unparalleled precision and throughput. Among these, the hydraulic pipe fittings machine stands out as a foundational technology, enabling the consistent production of high-quality fittings that meet stringent international standards. This sophisticated equipment is engineered to handle various materials—from carbon steel and stainless steel to specialized alloys—transforming raw stock into finished components with remarkable accuracy and repeatability. The underlying principles leverage hydraulic power, providing the immense force necessary for forming, bending, expanding, and cutting operations, all while maintaining tight dimensional tolerances. The evolution of these machines is closely tied to advancements in material science, automation, and digital control systems, allowing for greater versatility, reduced operational costs, and enhanced safety features. Modern hydraulic pipe fittings machines are not merely tools; they are integrated manufacturing solutions, often incorporating features like automated material handling, integrated quality control sensors, and intuitive human-machine interfaces (HMIs), propelling the industry towards smarter, more efficient production methodologies. Their indispensable role is evident across a spectrum of heavy industries, where the reliability of fluid conveyance systems directly impacts operational efficiency, safety, and environmental compliance, making the selection of the right machinery a critical strategic decision for manufacturers aiming for excellence in their product offerings. The commitment to innovation in this sector ensures that manufacturers can consistently meet the evolving demands for higher pressures, temperatures, and corrosive environments, delivering pipe fittings that perform flawlessly under extreme conditions and contribute significantly to the overall robustness and longevity of complex industrial infrastructures worldwide. This introduction lays the groundwork for a deep dive into the technical intricacies, application diversity, and strategic importance of these indispensable machines in modern manufacturing landscapes.

Deciphering Industry Trends and Technological Imperatives in Pipe Fitting Manufacturing

The global landscape of pipe fitting manufacturing is experiencing a profound transformation, driven by a confluence of technological advancements, evolving regulatory frameworks, and increasing demands for sustainability and operational efficiency. A significant trend is the accelerating adoption of Industry 4.0 principles, including the integration of the Internet of Things (IoT), artificial intelligence (AI), and advanced robotics into the production lifecycle of pipe fittings. This digital transformation enables real-time monitoring of machine performance, predictive maintenance protocols, and sophisticated data analytics that optimize manufacturing processes, reduce downtime, and enhance product consistency. For a hydraulic pipe fittings machine, this translates into intelligent sensors measuring hydraulic pressure, temperature, and component wear, alerting operators to potential issues before they escalate into costly failures. The emphasis on automation extends to material handling and finished product sorting, significantly reducing manual labor requirements and improving workplace safety. Another critical trend is the demand for higher precision and more complex geometries, particularly for applications in aerospace, nuclear power, and high-pressure oil and gas exploration, necessitating machines capable of executing intricate forming operations with micron-level accuracy. This push for precision is complemented by a growing focus on the metallurgy of pipe fittings, with a greater emphasis on exotic alloys such as Inconel, Monel, and Hastelloy, which offer superior resistance to corrosion, extreme temperatures, and harsh chemical environments. Manufacturers of tee forming machine and other specialized equipment must innovate to process these challenging materials efficiently, often requiring specialized tooling and enhanced power delivery systems. Furthermore, the industry is witnessing a shift towards modular and flexible manufacturing systems that can quickly adapt to varying production demands and custom specifications, facilitating shorter lead times and personalized solutions for niche markets.

Environmental sustainability and energy efficiency are no longer optional but foundational aspects of modern pipe fitting manufacturing. Companies are increasingly investing in hydraulic pipe fittings machine designs that consume less energy, utilize recyclable materials, and minimize waste generation. This includes advancements in hydraulic systems themselves, such as variable-speed pumps and closed-loop control systems that reduce energy consumption by matching power output precisely to demand, thereby cutting operational costs and reducing carbon footprints. Compliance with international standards such as ISO 14001 for environmental management and stringent emissions regulations is becoming a prerequisite for market access in many regions. The global supply chain dynamics are also influencing manufacturing strategies, with an increasing emphasis on localized production to mitigate geopolitical risks and reduce transportation costs and associated emissions. This encourages manufacturers to establish robust local production capabilities, often relying on advanced, flexible machinery that can be rapidly deployed and reconfigured. Finally, the integration of advanced diagnostic and remote service capabilities is becoming standard, allowing manufacturers to offer unparalleled after-sales support and proactive maintenance, further enhancing machine uptime and lifespan. These trends collectively underscore the dynamic and technologically intensive nature of the pipe fitting industry, pushing the boundaries of what is possible in precision manufacturing and sustainable industrial practices. Companies that embrace these imperatives, investing in cutting-edge hydraulic pipe fittings machine and tee forming machine technologies, are poised to lead the market, delivering superior products and services that meet the rigorous demands of the 21st-century industrial landscape. The continuous pursuit of innovation, efficiency, and sustainability remains the driving force behind the evolution of this critical manufacturing sector, ensuring the ongoing reliability and advancement of global infrastructure projects.

The Engineering Marvel: Manufacturing Process of Hydraulic Pipe Fittings Machines

The manufacturing of pipe fittings, facilitated by advanced machinery like the hydraulic pipe fittings machine, is a multi-stage, highly precise process that transforms raw materials into components engineered for specific fluid conveyance applications. The journey typically begins with the careful selection of raw materials, which are crucial for determining the final product's mechanical properties, corrosion resistance, and longevity. Common materials include various grades of carbon steel (e.g., A234 WPB, A105), stainless steel (e.g., 304, 316, Duplex), and specialized alloys like Inconel, Monel, and Hastelloy, chosen based on the intended operating environment—be it high pressure, high temperature, or highly corrosive media. Following material selection, the initial forming processes often involve hot forming techniques. For larger fittings and complex shapes, seamless pipes or plates are heated to forging temperatures (typically between 900°C and 1200°C) to enhance their malleability and allow for significant deformation without cracking. This hot forming might involve processes such as mandrel bending for elbows, or hot extrusion and pressing for tees and reducers. The hot forming ensures that the material grain structure is refined, enhancing strength and ductility. For a tee forming machine, this usually involves pushing a heated pipe against a die, with a mandrel forming the branch outlet simultaneously. The precision of temperature control and applied force during these stages is paramount, as it directly impacts the metallurgical integrity and dimensional accuracy of the fitting. After the initial forming, the fittings undergo cooling, which can be controlled to achieve specific material properties, followed by trimming of excess material, often performed by cutting machines that ensure clean and precise edges.

Subsequent stages involve cold working processes and intricate machining. Cold working, such as cold drawing or sizing, refines the dimensions and improves the surface finish of the fittings, often increasing their tensile strength. This is where advanced CNC (Computer Numerical Control) machining centers come into play, providing unparalleled precision for facing, beveling, threading, and drilling operations. The Q1245 Beveling Machine, for instance, is critical at this juncture, ensuring precise bevel angles for optimal welding preparation, a key factor in ensuring the integrity of pipeline joints. Each fitting undergoes rigorous quality control at various stages, adhering to stringent international standards such as ISO (International Organization for Standardization), ANSI (American National Standards Institute), ASME (American Society of Mechanical Engineers), and ASTM (American Society for Testing and Materials). These standards dictate everything from chemical composition and mechanical properties to dimensional tolerances and non-destructive testing (NDT) methodologies. NDT techniques, including ultrasonic testing (UT), radiographic testing (RT), magnetic particle testing (MPT), and liquid penetrant testing (LPT), are employed to detect internal flaws, cracks, or surface discontinuities, ensuring the fittings are free from defects that could compromise their performance. Furthermore, hydrotesting or pneumatic testing is conducted to verify the pressure retention capabilities of the fittings. The design life of these fittings, often exceeding 20-30 years, is a testament to the meticulous manufacturing processes and rigorous quality assurance protocols. They are extensively used across a broad spectrum of industries, including petrochemicals (for crude oil and gas processing), metallurgy (in steel mills and foundries), power generation (in thermal and nuclear plants), and critical infrastructure like water supply and drainage systems. In these applications, the advantages of fittings produced by a high-quality hydraulic pipe fittings machine are clear: superior anti-corrosion properties due to material integrity and surface finishes, enhanced energy efficiency through optimized flow dynamics and reduced pressure drops, and exceptional reliability even under aggressive operational conditions. This comprehensive approach ensures that every fitting contributes to a robust, long-lasting, and efficient fluid conveyance system, providing significant operational and safety benefits to end-users globally.

Figure 1: Conceptual diagram of a hydraulic press forming a pipe fitting component, highlighting key operational zones.

Technical Parameters and Performance Benchmarks of Advanced Hydraulic Pipe Fittings Machines

The performance and capability of a hydraulic pipe fittings machine are defined by a comprehensive set of technical parameters, each critical for assessing its suitability for specific manufacturing requirements. Understanding these specifications is essential for B2B decision-makers seeking to optimize their production lines and ensure the highest quality output. Key parameters include the machine's nominal pressure, typically measured in tons or kilonewtons, which dictates the maximum force it can exert for forming operations; this directly correlates with the largest pipe diameter and wall thickness it can process. For instance, machines designed for large-diameter oil and gas pipelines might offer pressing forces exceeding 5000 tons, while those for smaller, precision fittings may operate effectively at 500-1000 tons. The maximum working stroke and opening height are crucial for accommodating various fitting sizes and tooling configurations, ensuring versatility across different product lines. Furthermore, the machine's processing range, specified by minimum and maximum pipe diameters (e.g., DN15 to DN1200 or 1/2 inch to 48 inches) and wall thicknesses (e.g., Sch10 to Sch160), determines its application breadth. The tee forming machine, a specialized variant, will have specific parameters related to branch pipe diameter and main pipe diameter compatibility, along with the required forming pressure for creating the branch outlet without material thinning or cracking. The hydraulic system's power, usually indicated in kilowatts (kW) and hydraulic pump flow rate (L/min), directly influences the speed and efficiency of operations, impacting cycle times and overall production capacity. Advanced machines often feature energy-efficient servo-hydraulic systems, which only consume power on demand, significantly reducing operational costs compared to traditional constant-flow pump systems. Control systems are another vital technical aspect, with modern machines employing advanced PLC (Programmable Logic Controller) or CNC systems integrated with intuitive HMIs. These sophisticated control units allow for precise control over forming parameters, enabling complex process sequences, storing multiple production recipes, and providing diagnostic feedback.

Precision and repeatability are paramount in pipe fitting manufacturing, and these are quantified by parameters such as dimensional accuracy and angular tolerance. A high-quality hydraulic pipe fittings machine can achieve tolerances within ±0.5mm for dimensions and ±0.5 degrees for angles, ensuring that every fitting meets stringent industry standards for assembly and welding. The machine's structural rigidity, often achieved through heavy-duty welded steel frames and stress-relieved components, minimizes deflection under load, contributing to consistent precision over long operational periods. Integrated cooling systems for the hydraulic oil are essential for maintaining optimal operating temperatures, preventing oil degradation, and ensuring consistent performance, especially during continuous, high-intensity operations. Noise levels and energy consumption figures are also increasingly important parameters, reflecting a machine's compliance with occupational safety standards and its environmental footprint. For specialized machines like a tee forming machine, critical parameters also include the forming speed, the type of heating element (e.g., induction heating for faster, localized heating), and the ability to process different material grades without compromising integrity. When evaluating potential investments, manufacturers often look for machines with a high degree of automation readiness, meaning they can be easily integrated into automated production lines with robotic handling systems, further enhancing throughput and reducing labor costs. The table below provides a representative overview of typical technical specifications for a high-performance hydraulic pipe fittings machine, illustrating the depth of engineering that goes into these indispensable industrial assets and highlighting the critical metrics that define their operational excellence and value proposition in the competitive global market. These detailed technical insights empower purchasing teams and engineering departments to make informed decisions, selecting machinery that not only meets current production demands but also offers scalability and adaptability for future requirements, ensuring a competitive edge in advanced manufacturing.

| Parameter | Value/Range | Description |

|---|---|---|

| Nominal Pressing Force | 1000 - 5000 Tons (10,000 - 50,000 KN) | Maximum force for forming operations, dictates material and size capacity. |

| Processing Diameter Range (DN) | DN50 - DN1200 (2" - 48") | Range of pipe diameters the machine can process. |

| Max. Wall Thickness | Sch10 - Sch160 (3mm - 60mm) | Maximum thickness of material that can be formed. |

| Working Stroke (mm) | 500 - 2500 mm | Vertical travel distance of the press ram. |

| Opening Height (mm) | 1000 - 3500 mm | Maximum space available for tooling and workpiece. |

| Motor Power | 75 kW - 450 kW (or higher) | Total installed power of the hydraulic pump motors. |

| Hydraulic System Pressure | 25 MPa - 31.5 MPa | Operating pressure of the hydraulic circuit. |

| Control System | Siemens/Mitsubishi/Rockwell PLC with HMI | Advanced programmable logic controller and human-machine interface. |

| Positional Accuracy | ±0.1 mm | Precision of ram positioning during forming. |

| Repetitive Accuracy | ±0.05 mm | Consistency of repeated operations. |

| Noise Level | < 80 dB (A) | Operating noise emission, important for workplace safety. |

Versatile Applications and Strategic Advantages in Diverse Industrial Ecosystems

The robust capabilities of a hydraulic pipe fittings machine extend its utility across an extraordinarily broad spectrum of industrial applications, making it an indispensable asset in sectors where reliable fluid and gas conveyance is critical. In the petrochemical industry, for example, these machines are fundamental for producing fittings capable of withstanding extreme pressures, corrosive hydrocarbons, and wide temperature fluctuations encountered in oil refineries, gas processing plants, and offshore drilling platforms. The demanding conditions in this sector necessitate fittings that ensure zero leakage and long-term structural integrity, directly impacting operational safety and environmental compliance. Similarly, in the power generation sector, encompassing thermal, nuclear, and renewable energy plants, pipe fittings produced by these advanced machines manage the flow of high-temperature steam, cooling water, and fuel, forming the backbone of energy production infrastructure. The precision and material compatibility offered by modern hydraulic pipe fittings machine ensure that components like bends, reducers, and especially tees (formed by a specialized tee forming machine) can reliably operate under constant thermal cycling and high pressures without failure, which is paramount for continuous power supply. The metallurgical industry, including steel mills and non-ferrous metal production, also heavily relies on these machines for producing fittings used in cooling systems, hydraulic power units, and material transport lines, often requiring materials with high wear resistance and thermal stability. Beyond heavy industry, the utility extends to public utilities, particularly in water supply and drainage systems, where large-diameter pipe fittings are crucial for efficient urban infrastructure development, requiring components that can withstand soil stresses, water pressure, and long-term corrosion. The ability of the machine to handle various materials—from standard carbon steel to high-grade stainless steel and special alloys—allows manufacturers to cater to these diverse industry-specific requirements with a single, versatile platform, significantly reducing the need for multiple specialized machines and optimizing capital expenditure.

The technical advantages offered by a state-of-the-art hydraulic pipe fittings machine are manifold, directly translating into tangible benefits for manufacturers and end-users. Foremost among these is the superior product quality achieved through precise control over forming processes. The hydraulic power ensures uniform material flow and deformation, minimizing stress concentrations and internal defects that could lead to premature failure. This precision results in fittings with exact dimensional accuracy and optimal metallurgical properties, enhancing their performance and prolonging their service life, often exceeding industry benchmarks by significant margins. Another key advantage is the remarkable efficiency and productivity boost. Modern machines are designed for high throughput, with rapid cycle times facilitated by advanced hydraulic systems and automated material handling. This efficiency is critical for meeting tight production deadlines and reducing per-unit manufacturing costs. Energy efficiency is also a growing advantage, with servo-hydraulic systems significantly reducing power consumption by matching energy output to demand, leading to substantial operational cost savings and a reduced environmental footprint, aligning with global sustainability initiatives. Furthermore, the versatility of these machines allows for the production of a wide range of fitting types and sizes, from small-bore precision components to large-diameter industrial fittings, using the same base machine with different tooling, offering unparalleled flexibility in manufacturing. The inherent robustness of hydraulic systems contributes to exceptional machine durability and reliability, with minimal downtime for maintenance, ensuring continuous production. For manufacturers, investing in such advanced machinery means not only producing superior quality fittings but also gaining a competitive edge through increased efficiency, reduced operational expenditure, and the flexibility to adapt to evolving market demands. This adaptability is particularly crucial for custom fabrication projects where unique dimensions or material specifications are frequently required. The combined impact of precision, efficiency, and versatility solidifies the position of the hydraulic pipe fittings machine as a cornerstone technology in the modern manufacturing landscape, driving innovation and excellence in industrial fluid conveyance systems globally.

Figure 2: Illustrative application of pipe fittings in a complex petrochemical processing plant, emphasizing robustness.

Manufacturer Comparison: Navigating the Landscape of Hydraulic Pipe Fittings Machine Providers

Selecting the right manufacturer for a hydraulic pipe fittings machine is a strategic decision that profoundly impacts production quality, operational efficiency, and long-term return on investment. The global market is populated by numerous providers, each with distinct strengths in terms of technology, specialization, and after-sales support. A comprehensive comparison goes beyond initial purchase price, delving into aspects like technological innovation, machine robustness, energy efficiency, customization capabilities, and the quality of customer service and technical support. Leading manufacturers typically distinguish themselves through their commitment to R&D, continually integrating the latest advancements in hydraulic control, automation, and material science into their machine designs. For instance, some may specialize in high-tonnage machines for large-diameter pipe fittings required by the oil and gas sector, while others may focus on compact, high-precision models ideal for aerospace or pharmaceutical applications where exceptionally tight tolerances are non-negotiable. The reliability of components used, such as hydraulic pumps, valves, and electrical control systems (e.g., Siemens, Rexroth, Parker, Mitsubishi), is a crucial differentiator, directly influencing machine uptime and maintenance frequency. Manufacturers with established global supply chains for these critical components often provide superior product longevity and easier access to spare parts. Furthermore, the level of integration with Industry 4.0 technologies, such as IoT-enabled remote diagnostics, predictive maintenance algorithms, and seamless MES (Manufacturing Execution System) connectivity, sets advanced providers apart, offering a future-proof investment. Companies with a long service history and extensive client testimonials, particularly from Fortune 500 companies or those with ISO 9001 and CE certifications, usually signify a higher degree of authoritativeness and trustworthiness in the market.

Customization capabilities represent another vital factor in manufacturer comparison. Many industrial operations require unique pipe fitting dimensions, materials, or production volumes that standard machines cannot efficiently handle. A manufacturer capable of offering bespoke solutions—modifying machine stroke, tonnage, tooling interface, or integrating specialized material handling systems—can provide a significant competitive advantage. This flexibility often extends to the software and HMI, allowing for tailored production recipes and improved operator workflow. The after-sales support ecosystem, including installation, commissioning, operator training, maintenance contracts, and readily available spare parts, is arguably as critical as the machine itself. A manufacturer offering comprehensive, prompt, and expert technical support minimizes potential downtime and ensures that the investment continues to deliver peak performance throughout its lifespan. Companies that provide remote diagnostic services and rapid on-site support demonstrate a deeper commitment to customer success. Furthermore, the overall cost of ownership (TCO) should be a key metric, factoring in energy consumption, maintenance costs, and potential for future upgrades, rather than focusing solely on the upfront purchase price. The table below illustrates a comparative analysis framework, highlighting key considerations when evaluating different manufacturers of hydraulic pipe fittings machine and tee forming machine, guiding potential buyers towards making an informed and strategic investment decision that aligns with their long-term business objectives and operational requirements, fostering a productive and reliable manufacturing environment for years to come. This thorough evaluation process ensures that the selected machinery not only meets current production demands but also provides a scalable and adaptable solution for future growth and technological advancements in the ever-evolving pipe fitting manufacturing landscape.

| Feature Category | Manufacturer A (e.g., World Steel Material Co., Ltd.) | Manufacturer B (Leading Competitor) |

|---|---|---|

| Core Specialization | Wide Range (Standard to Heavy-Duty) | Niche (e.g., High-Precision Small Diameter) |

| Technological Innovation | High (Servo-Hydraulics, IoT Integration) | Moderate (Traditional Hydraulics) |

| Component Quality | Premium (Tier-1 Global Brands) | Standard (Regional Suppliers) |

| Customization Capability | Extensive (Bespoke Designs, Tooling) | Limited (Standard Modifications) |

| After-Sales Support | Global Network, Remote Diagnostics, Training | Regional Support, Basic Maintenance |

| Certifications & Compliance | ISO 9001, CE, ASME B31.3 | CE Compliant |

| Energy Efficiency | High (Servo-Hydraulic, Reduced Idling) | Moderate (Standard Pump Systems) |

| Lead Time & Delivery | Optimized for Global Logistics (e.g., 12-16 weeks for standard models) | Varies, Potentially Longer for Custom Orders |

Tailored Solutions: Customization and Bespoke Engineering for Hydraulic Pipe Fittings Machines

In an industrial landscape increasingly characterized by niche applications and highly specialized project requirements, the ability to procure a customized hydraulic pipe fittings machine is becoming a significant competitive differentiator for manufacturers. While standard models cater to a broad range of common pipe fitting types and sizes, many high-value projects, particularly in sectors like aerospace, defense, nuclear energy, or bespoke architectural design, demand unique specifications that go beyond off-the-shelf capabilities. Customization in the context of a hydraulic pipe fittings machine can encompass various aspects, starting with the adjustment of fundamental machine parameters such as increased pressing force to handle exceptionally thick-walled pipes or advanced alloys, or an extended working stroke and opening height to accommodate unusually large-diameter fittings or complex, multi-stage forming operations. It might also involve modifications to the tooling interface, allowing for quick changeovers between different fitting types or proprietary die designs that achieve specific metallurgical properties or aesthetic finishes. Beyond basic adjustments, bespoke engineering can integrate specialized automation solutions, such as robotic loading and unloading systems, automated material feeding mechanisms for continuous production runs, or advanced inline inspection systems that perform real-time quality control checks (e.g., laser scanning for dimensional accuracy, eddy current testing for surface defects) without interrupting the manufacturing flow. For a tee forming machine, customization could mean developing specific branch forming tools for non-standard angles or eccentric tees, or integrating induction heating systems for precise temperature control on exotic materials, preventing material degradation or stress cracking during the forming process. The control system itself can be customized with bespoke software algorithms to optimize forming cycles for specific material grades, minimize energy consumption for certain production batches, or provide advanced diagnostic capabilities tailored to the client's existing maintenance protocols.

The value proposition of custom hydraulic pipe fittings machine solutions lies in their ability to precisely meet specific operational challenges, thereby maximizing efficiency, reducing material waste, and enhancing product quality for highly specialized applications. For instance, a client requiring the production of high-pressure fittings for deep-sea oil and gas exploration might need a machine with enhanced structural rigidity, advanced material processing capabilities, and integrated non-destructive testing features to ensure every component meets the stringent API (American Petroleum Institute) standards. Another client in the pharmaceutical industry might prioritize ultra-hygienic design features, highly polished surfaces, and minimal dead spaces within the machine's material contact areas to prevent contamination, requiring specialized finishes and cleaning systems. Engaging a manufacturer with robust R&D capabilities and a proven track record in custom engineering is crucial for successful bespoke projects. This involves a collaborative design process, starting with a thorough understanding of the client's specific needs, followed by detailed engineering proposals, simulations, and prototype testing to validate the proposed solution before full-scale manufacturing. The benefits extend beyond direct production efficiency; a customized machine can significantly reduce post-processing steps, lower labor costs, and provide a unique competitive edge in specific market segments by enabling the production of otherwise unfeasible components. This level of tailored engineering demonstrates a manufacturer's deep expertise and commitment to partnership, transforming a capital expenditure into a strategic investment that unlocks new production capabilities and addresses complex engineering challenges, ensuring that the hydraulic pipe fittings machine becomes an integral and perfectly optimized part of the client's advanced manufacturing ecosystem.

Figure 3: Illustration of a specialized tooling setup on a hydraulic pipe fittings machine for unique component geometry.

Real-World Impact: Application Case Studies and Client Success Stories

The true testament to the value and performance of a hydraulic pipe fittings machine lies in its real-world application and the demonstrable success stories of clients who have integrated this technology into their manufacturing operations. These case studies provide tangible evidence of the machine's capabilities, illustrating how specific challenges were overcome, and significant improvements were achieved in production efficiency, product quality, and cost savings. Consider a multinational oil and gas pipeline constructor that faced increasing demand for large-diameter, high-pressure elbows and reducers made from specialized steel alloys. Their existing machinery struggled with the material hardness and required excessive post-processing, leading to bottlenecks and quality inconsistencies. By investing in a high-tonnage hydraulic pipe fittings machine equipped with advanced heating and forming capabilities, this client was able to process these challenging materials with unprecedented efficiency. The machine's precise control over heating cycles and forming pressure reduced material stress and improved grain structure, resulting in fittings that not only met but exceeded API 5L and ASME B16.9 standards for dimensional accuracy and mechanical strength. This led to a 30% reduction in scrap rate and a 25% increase in production throughput, significantly enhancing their competitive position in large-scale infrastructure projects. This particular success story highlights the critical role of the right machinery in enabling companies to tackle complex engineering challenges and capitalize on high-demand market segments, demonstrating the direct link between technology investment and market leadership. The client specifically noted the ease of integration into their existing manufacturing execution system, allowing for seamless data flow and process optimization, further validating the machine's advanced capabilities and smart manufacturing readiness.

Another compelling case involves a leading industrial valve manufacturer that sought to vertically integrate the production of their own pipe tees to ensure consistent quality and reduce reliance on external suppliers. Their requirement was for a versatile tee forming machine capable of producing a wide range of tee sizes, including specialized reducing tees, with high precision and minimal tooling changeover time. The chosen solution was a custom-engineered hydraulic tee forming machine featuring an innovative quick-change tooling system and a servo-hydraulic power unit for optimized energy consumption. This investment allowed the client to bring tee production in-house, gaining full control over material quality and manufacturing tolerances. The machine's ability to precisely form tees with consistent wall thickness and branch alignment dramatically reduced the need for secondary machining operations and welding preparation, leading to a 40% improvement in production cycle time for tees. Furthermore, the integration of advanced process monitoring tools enabled real-time quality checks, virtually eliminating defects and drastically improving the first-pass yield rate. Customer feedback from this client underscored the significant improvements in supply chain resilience and cost efficiency, proving that strategic investments in a hydraulic pipe fittings machine can deliver substantial long-term benefits beyond mere production volume. These practical examples underscore that the acquisition of an advanced hydraulic pipe fittings machine is not just a procurement decision but a strategic move that can fundamentally transform manufacturing capabilities, elevate product quality, and enhance a company's overall market competitiveness by enabling superior performance and unlocking new revenue streams through enhanced product offerings and operational efficiencies. Such verifiable results are powerful affirmations of the technological prowess and economic benefits inherent in modern pipe fitting manufacturing equipment.

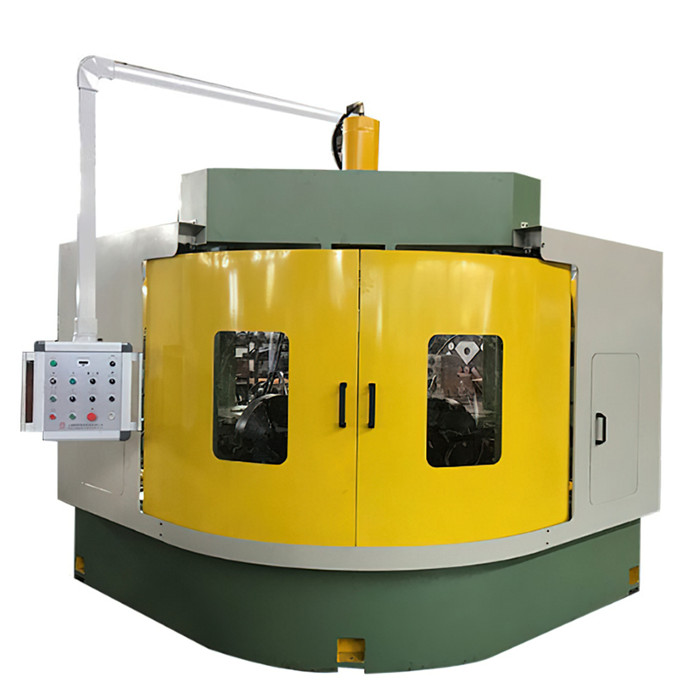

Figure 4: A modern production line featuring a hydraulic pipe fittings machine, demonstrating high throughput.

Ensuring Trust: Quality Assurance, Warranty, and Comprehensive Support

In the B2B sphere, especially when investing in capital equipment like a hydraulic pipe fittings machine, trust is built on a foundation of verifiable quality, clear commitments, and robust after-sales support. World Steel Material Co., Ltd., as a professional manufacturer, understands that the acquisition of such critical machinery represents a significant long-term investment, and therefore, every aspect of the customer journey, from initial inquiry to decades of operation, is underpinned by a commitment to excellence and transparency. Our products, including the Q1245 Beveling Machine and our range of advanced hydraulic pipe fittings machine and tee forming machine solutions, undergo rigorous multi-stage quality assurance protocols. This starts with the selection of premium-grade raw materials and components, sourced from globally recognized suppliers who adhere to ISO 9001 quality management standards. During manufacturing, each critical assembly and sub-assembly is subjected to stringent in-process inspections, utilizing precision measurement tools and non-destructive testing methods to ensure compliance with design specifications. Before dispatch, every machine undergoes a comprehensive factory acceptance test (FAT), simulating real-world operational conditions to verify performance parameters such as pressing force accuracy, positional repeatability, cycle times, and energy consumption. This meticulous testing ensures that the machine meets its published specifications and is ready for immediate deployment upon arrival at the client's facility. Our adherence to international certifications like CE (Conformité Européenne) and compliance with industry-specific standards like ASME Boiler and Pressure Vessel Code (BPVC) for structural integrity further underscore our commitment to global quality benchmarks and regulatory requirements. Our service team boasts years of experience in the field, with specialized expertise in mechanical, electrical, and hydraulic engineering, enabling us to provide insightful technical consultation and prompt issue resolution, ensuring maximal uptime for your production lines.

Beyond the initial quality and certification, our commitment to customer trust is solidified through our comprehensive warranty and support programs. We typically offer a standard 12-to-24-month warranty on our hydraulic pipe fittings machine from the date of commissioning, covering major components and manufacturing defects, providing peace of mind to our clients. Details regarding extended warranty options and tailored service contracts are available upon request, allowing clients to customize their level of coverage. Our delivery cycle is meticulously managed, with typical lead times for standard models ranging from 12 to 16 weeks, depending on customization requirements and current production schedules. We provide transparent updates throughout the manufacturing and shipping process, ensuring clients are well-informed. Post-installation, our dedicated customer support extends beyond troubleshooting. We offer comprehensive operator training programs, either on-site or remotely, to ensure your personnel are fully proficient in operating, maintaining, and optimizing the machine's performance. Our technical support team is accessible via multiple channels—phone, email, and dedicated online portal—providing rapid response times for technical queries, diagnostic assistance, and spare parts ordering. We maintain a robust inventory of critical spare parts, ensuring quick dispatch to minimize any potential downtime. Furthermore, we provide detailed technical documentation, including operation manuals, maintenance guides, and hydraulic/electrical schematics, empowering your in-house teams with the necessary knowledge. For complex issues, our field service engineers are available for on-site visits, offering expert diagnostics, repairs, and preventative maintenance services. This holistic approach to quality assurance, warranty, and comprehensive customer support underscores our dedication to fostering long-term partnerships and ensuring that your investment in a hydraulic pipe fittings machine continues to deliver optimal performance and significant value throughout its operational lifespan, reinforcing our position as a trusted partner in advanced pipe fitting manufacturing.

Frequently Asked Questions (FAQ)

Q: What materials can your hydraulic pipe fittings machine process?

A: Our machines are designed to process a wide range of materials, including carbon steel, stainless steel (304, 316, Duplex, Super Duplex), alloy steels (P11, P22), and specialized exotic alloys such as Inconel, Monel, and Hastelloy, depending on the specific model and tooling configuration. We can provide tailored solutions for challenging materials.

Q: What is the typical lead time for a new machine order?

A: For standard models of the hydraulic pipe fittings machine, the typical lead time is between 12 to 16 weeks from order confirmation to ex-works delivery. Highly customized machines or those with specialized components may require a slightly longer lead time, which will be specified in the proposal.

Q: Do you offer installation and training services?

A: Yes, we provide comprehensive installation and commissioning services globally. Our experienced technicians will ensure proper setup and integration into your facility. We also offer extensive operator and maintenance training programs, both on-site and remotely, to ensure your team is fully proficient in operating and maintaining the hydraulic pipe fittings machine.

Q: What kind of warranty and after-sales support can I expect?

A: We offer a standard 12 to 24-month warranty on our machinery from the date of commissioning. Our dedicated after-sales support includes telephone/email support, remote diagnostics, readily available spare parts, and on-site technical assistance by our field service engineers for complex issues, ensuring minimal downtime and long-term operational reliability of your tee forming machine and other equipment.

Q: How does your machinery contribute to energy efficiency?

A: Many of our advanced hydraulic pipe fittings machine models incorporate servo-hydraulic systems that only consume power on demand, significantly reducing energy consumption compared to traditional constant-flow pump systems. This results in substantial operational cost savings and a reduced environmental footprint, aligning with modern sustainability goals. Energy consumption data can be provided in detail per machine model.

Further Industry Insights & References

For those seeking to delve deeper into the evolving technological landscape of pipe fitting manufacturing and the broader industrial machinery sector, several authoritative resources offer valuable insights. The advancements in hydraulic systems, material science, and automation continue to be a subject of intense research and development globally.

-

•

Journal of Manufacturing Science and Engineering (ASME): Provides peer-reviewed research on advanced manufacturing processes, including metal forming and automated production systems, directly relevant to the sophisticated operations of a hydraulic pipe fittings machine.

https://asmedigitalcollection.asme.org/manufacturingscience -

•

Hydraulics & Pneumatics Magazine: A leading industry publication offering technical articles, product news, and market trends in fluid power technology, crucial for understanding the core mechanics and innovations in hydraulic pipe fittings machine design.

https://www.hydraulicspneumatics.com/ -

•

Oil & Gas Journal: Offers comprehensive insights into global energy markets, infrastructure development, and pipeline technology, providing context for the high-demand applications of fittings produced by a tee forming machine.

https://www.ogj.com/ -

•

NACE International (AMPP) - Association for Materials Protection and Performance: Publishes standards and research on corrosion prevention and materials performance, which are directly relevant to the longevity and material selection for pipe fittings.

https://www.ampp.org/

These resources provide a deeper understanding of the scientific principles, engineering challenges, and market dynamics that shape the industrial landscape where sophisticated machinery like the hydraulic pipe fittings machine operates, fostering continuous innovation and higher standards of manufacturing excellence.

Post time: Aug . 10, 2025 07:40