Company Overview

Enterprise Name: Beijing Sinoworld Steel Material Co., Ltd.

Official Website: https://www.world-steelmaterial.com

Email: garvinliu@world-steelmaterial.com

Mobile: 0086 18610666788

Address: Rm 1103, Shangpintaihu Bld 3#, Tongzhou District, Beijing, China

The global demand for hydraulic pipe fittings machine and tee forming machine is rapidly evolving with rising infrastructure projects, oil & gas transport systems, manufacturing automation, and a need for more reliable high-pressure pipelines. According to the latest ResearchAndMarkets report, the pipe fitting equipment market is projected to grow at 6.4% CAGR from 2024 to 2029.

- Automation is driving consistency and productivity across pipe fitting plants.

- Modern machines, like advanced hydraulic pipe fittings machine and tee forming machines, incorporate smart controls & quick-change modules for diverse production needs.

- Sustainability: Energy-saving hydraulic systems and eco-friendly technology are now prioritized.

- Precision manufacturing for seamless, leak-proof connections in industries like petrochemical and automotive.

Industry forums such as Eng-Tips Forums discuss recent advancements, reliability improvements, and the shift towards digitally integrated fabrication solutions that enhance traceability & efficiency.

Choosing the right hydraulic pipe fittings machine corelates with application requirements such as diameter, wall thickness, output precision, and automation. Below is a summary table of typical specifications found via top supplier and manufacturer documentation:

| Parameter | Typical Range/Value | Description |

|---|---|---|

| Processing Diameter | Φ21 – Φ630 mm | Nominal pipe size suitability |

| Operation | Fully-automatic / semi-automatic | Automation level: feeding, clamping, cutting |

| Max Wall Thickness | 1.5 – 35 mm | Pipes with different wall strengths |

| Working Pressure | 16 – 31.5 MPa | Hydraulic system capacity |

| Forming Force | 100 – 1200 tons | Maximum machine press force |

| Hydraulic System | Servo/Standard / Energy-saving | Power consumption and efficiency options |

| Control System | PLC + HMI Touchscreen | Smart, user-friendly operation |

| Application | Elbows, tees, reducers, end forming | Multiple fitting types supported |

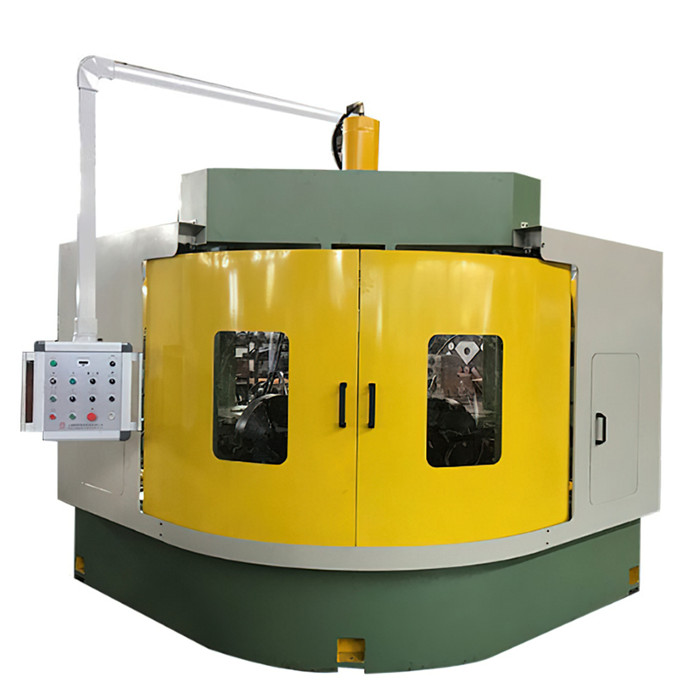

PRODUCT NAME: Q1245 BEVELLING MACHINE

APPLICATION: PIPE END AND FITTING ENDS BEVELLING JOB

Technique Data:

- Pipe diameter range: 60mm–457mm

- Wall thickness: 2.5–25mm

- Beveling speed: 1.8–3.0min/pipe (based on size & wall)

- Max output: up to 16 pipes/hour (standard size)

- PLC + Touchscreen HMI for operation

- Hydraulic power: 17–25kW, Max system pressure: 21MPa

- CE Certified, meets ISO 9001:2015

The hydraulic pipe fittings machine Q1245 model by Beijing Sinoworld Steel Material Co., Ltd. is engineered specifically for industrial scale pipe end beveling. Its ability to process multiple pipe diameters and wall thicknesses in rapid cycles makes it a prime selection for pipeline manufacturers, power plants, and oil & gas refineries.

Notably, it integrates smart hydraulic management, quick-change tooling, strict angle control, and safety interlocks—meeting the highest global standards for durability and performance.

- Oil & Gas Pipeline Construction: Enables fast and reliable production of elbows, tees, reducers, and custom pipe ends needed for safe transmission lines.

- Power Station & Boiler Manufacturing: Delivers precision-fit and durable joint fittings that are essential to boiler tubes and heat exchangers.

- Automotive & Shipbuilding: Facilitates high-volume fabrication of exhausts, cooling systems, and custom hydraulics.

- Municipal Water Systems: Ensures leak-proof connections in drinking water, sewage, and fire protection piping networks.

- Process Plants (Petrochemical, Chemical): Supports highly specialized corrosive- and temperature-resistant pipe system requirements.

With the rise of smart manufacturing, the integration of digital, automated hydraulic pipe fittings machine sets new benchmarks for both productivity and traceable quality assurance, as analyzed in ScienceDirect – Manufacturing Processes Journal.

- Proven Authority: Over 15 years specializing in pipe fittings equipment manufacturing & project solutions.

- Comprehensive Quality Control: All machines are tested per ISO9001 procedures.

- Dedicated R&D: Continuous innovation in hydraulic, forming, and automation modules fueled by industrial research.

- Strong Export Track Record: Products delivered to 43+ countries—trusted by EPC, pipeline, and OEM clients globally.

- After-Sales & Training: Complete support from installation to lifecycle maintenance and operational training.

- Professional Team: Certified engineers, technical consultants, and responsive customer service, reachable 24/7 at garvinliu@world-steelmaterial.com

As industry 4.0 advances, the hydraulic pipe fittings machine segment is set to benefit greatly from digital innovation, integrated sensors, predictive maintenance, and sustainable hydraulics. Companies like Beijing Sinoworld Steel Material Co., Ltd. are at the forefront—fusing traditional reliability, modern controls, data analytics, and application-centric design. Proven through peer forums such as Eng-Tips Forums and comprehensive studies in Journal of Manufacturing Processes (Elsevier).

For expert solutions and possible partnership, contact: Beijing Sinoworld Steel Material Co., Ltd. — garvinliu@world-steelmaterial.com | 0086 18610666788

References:

ResearchAndMarkets: Pipe Fittings Equipment Market

Eng-Tips Industry Forums

Journal of Manufacturing Processes (Elsevier)

Q1245 Beveling Machine by Beijing Sinoworld Steel Material Co., Ltd.

ISO 9001 Quality Management

Post time: Jul . 24, 2025 12:01