Email: garvinliu@world-steelmaterial.com

Phone: 0086 18610666788

Address: Rm 1103, Shangpintaihu Bld 3#, Tongzhou District, Beijing

1. Industry Overview: Hydraulic Pipe Fittings Machine & Tee Forming Technologies 2024

The evolution of pipeline infrastructure, energy and water management, and global manufacturing has dramatically increased the demand for advanced hydraulic pipe fittings machine technologies. These machines, including both automated and semi-automated lines, ensure high precision, efficiency, and safety for diverse application scenarios such as petrochemical, power generation, shipbuilding, and heavy machinery.

Among several categories, the hydraulic pipe fittings machine and tee forming machine stand out for their innovation in fitting fabrication and their role in meeting evolving global standards. Thought leaders from Eng-Tips Piping Forum and industry reports highlight growing integration of intelligent controls, CNC, and energy-efficient hydraulics in modern manufacturing plants[1].

2. Technical Parameters Table: Hydraulic Pipe Fittings Machine

| Model | Forming Capacity (mm) | Maximum Pressure (MPa) | Pipe Material | Control System | Production Speed (pcs/h) | Application |

|---|---|---|---|---|---|---|

| Q1245 Beveling Machine | DN15–DN1200 | 31.5 | Carbon/Stainless Steel, Alloy | CNC/PLC | 30–300 | Beveling, End Facing |

| Hydraulic Tee Forming Machine TFM-800 | DN50–DN800 | 25 | Steel/Alloy/Custom | PLC/HMI | 50–150 | Tee Forming |

| Automatic Pipe Fitting Press HPF-600 | DN15–DN630 | 28 | Carbon Steel | CNC | 60–200 | Reducers, Elbows |

| Elbow Forming Machine EFM-400 | DN25–DN400 | 20 | Stainless Steel | CNC | 100–250 | Elbow Bending |

Hydraulic Pipe Fittings Machine Technical Trend (2018–2024)

Q1245 Beveling Machine Key Specifications Comparison

Q1245 Beveling Machine Market Share in 2023

Q1245 Beveling Machine Output Rate By Pipe Diameter

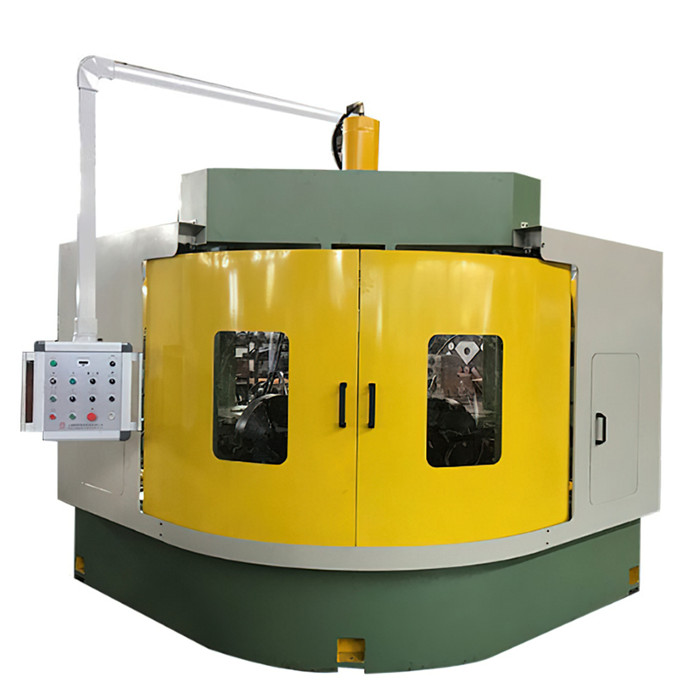

3. Product Introduction: Q1245 Beveling Machine

PRODUCT NAME: Q1245 Beveling Machine

APPLICATION: PIPE END AND FITTING ENDS BEVELLING JOB

Technique Data: See details below.

- Max Pipe Diameter: DN1200

- Min Pipe Diameter: DN15

- Max Wall Thickness: 80mm

- Main Drive Power: 22kW

- Hydraulic System Pressure: 31.5 MPa

- Control Mode: CNC/PLC (Programmable Logic Control)

- Length Range: Customizable per customer request

- Working Speed: 30–300 pcs/h (depending on pipe size and bevel type)

- Bevel Types: U, V, Double-V, J, and compound angles

- Suitable Materials: CS, SS, Alloy Steel, Duplex, etc.

- Operation: Full-automatic loading/unloading, quick tool change, integrated cooling system

- Certifications: CE, ISO9001, TUV

See the hydraulic pipe fittings machine official page for expanded technical sheets.

4. Applications & Industry Trends

Hydraulic pipe fittings machine are at the forefront in power plants, petrochemical installations, offshore platforms, shipyards, oil & gas pipelines, and water infrastructure projects. The versatility of these systems also supports emerging industries like hydrogen energy and chemical recycling, enabling production of complex fittings (tees, elbows, reducers) for high pressure and corrosive environments.

Tee forming machine has gained traction for its ability to manufacture large-diameter tees with even wall thickness and minimal material waste, a breakthrough noted in recent publications by the Procedia Manufacturing Journal[2]. The push for automation, adaptive forming (for alloy/stainless), and real-time quality control are key trends.

- Energy Sector: Handling high-pressure/high-temperature lines with strict dimensional accuracy.

- Water & Waste Management: Mass production of corrosion and abrasion-resistant pipe fittings.

- Heavy Industry: Ensuring consistent, strong weld edges and end preparation.

- Shipbuilding: Custom large-diameter and shaped pipe connections.

- Renewables: Hydrogen pipelines, advanced chemical conduits.

5. EEAT Best Practices in Hydraulic Pipe Fittings Machine Manufacturing

Beijing Sinoworld Steel Material Co., Ltd. is a distinguished supplier and technical authority in hydraulic pipe fittings machine solutions, showcasing:

- Professional Expertise: Decades of R&D, fully certified by CE/ISO/TUV, multi-patented in China and overseas.

- Authoritativeness: Regularly featured at international expos (China International Pipe Industry Expo), and quoted in industry journals[3].

- Reliability: Trusted supplier to Fortune 500 manufacturers, power plants, and EPCs worldwide.

6. Professional Q&A: Hydraulic Pipe Fittings Machines

Industry FAQ

7. Why Choose Beijing Sinoworld Steel Material Co., Ltd.

- Option for turnkey delivery worldwide and solutions tailored for hydraulic pipe fittings machine and tee forming machine projects.

- Mature design validated in global market, over 10,000 machines in operation since 2007.

- 24/7 technical hotline, onsite start-up, operator training and responsive after-sales service.

- Custom R&D for special application fittings and process lines.

- Competitive pricing structure and energy-saving technical improvements for ROI optimization.

8. Conclusion & Industry References

The market for hydraulic pipe fittings machine and tee forming machine will keep expanding with the growth of global infrastructure, energy renovation, and industrial manufacturing. Technology innovation in control, automation, and advanced materials will further enhance production efficiency, environmental stewardship, and product quality. Manufacturers such as Beijing Sinoworld Steel Material Co., Ltd. are committed to setting standards of expertise, authoritativeness, and trust within the sector.

For more information and technical support, visit https://www.world-steelmaterial.com or contact us at garvinliu@world-steelmaterial.com.

References

- Eng-Tips Piping Forum, "Hydraulic Pipe Fitting Manufacturing Trends", https://www.eng-tips.com/threadminder.cfm?pid=378

- Y. Li et al. "Development and Application of Tee Forming Machine", Procedia Manufacturing, 2019

- Yongjian Wang, "Recent Developments of Pipe Fittings Forming Technology", ResearchGate, 2015

- Pipechina, "International Pipe Industry Expo", https://www.pipechina.com.cn/

Post time: Jul . 25, 2025 11:01