1. Overview and Industry Trends in Boiler Steel Pipe

Rapid infrastructure growth, stricter emission standards, and the shift to clean energy sources have catapulted the demand for boiler steel pipe globally. According to MarketsandMarkets, the boiler tubes market is projected to reach USD 18.07 billion by 2026, growing at a CAGR of 6.0% (2021-2026).

- Power Generation Dominant sector accounting for over 42% of global boiler steel pipe consumption.

- Seamless Boiler Tubes Demand Rising due to high-pressure and temperature operations.

- Regional Focus Asia-Pacific remains the largest and fastest-growing market.

- Compliance Increasing adoption of ISO, ANSI, ASTM, and EN standards by manufacturers.

2. What is Boiler Steel Pipe? In-depth Product Analysis

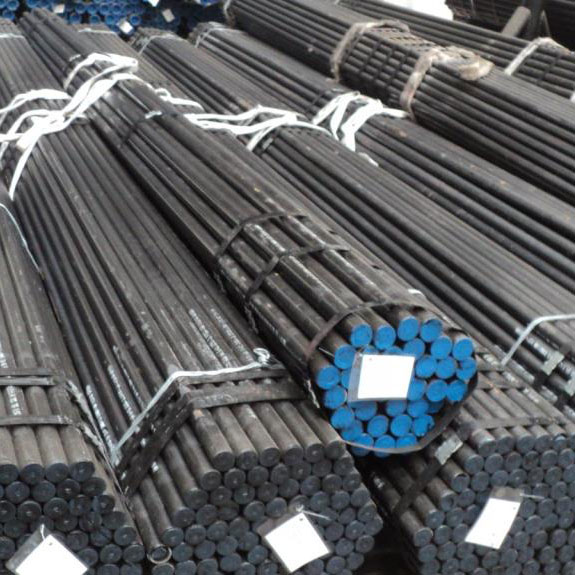

Boiler steel pipe refers to specialty steel pipes designed for high- and low-pressure boiler systems. These pipes must withstand extreme conditions—high temperature, high pressure, and aggressive media—making rigorous quality, reliability, and safety essential.

Seamless boiler tubes are widely used due to their outstanding resistance to rupture, creep (slow deformation under high temp/stress), and corrosion.

View Detailed Boiler Steel Pipe Specs & Supply Chain3. Boiler Steel Pipe Manufacturing Process

The production of boiler steel pipe incorporates advanced material science, precision forming, strict heat treatment, and non-destructive testing (NDT). See the streamlined process below:

Key Manufacturing Technologies: Hot rolling, seamless extrusion, advanced CNC machining for precision dimensions, multi-stage heat treatment, high-pressure hydrostatic and eddy current inspection in line with ISO 9001, EN 10216, ASME SA213/SA210, and GB/T 5310.

4. Main Technical Parameters & Product Specs

| Parameter | Specification (Typical Range) | Industry Standard | Application |

|---|---|---|---|

| Outer Diameter (OD) | 21.3mm – 630mm | EN 10216, ASTM A192/A213 | Steam, Superheater tubes |

| Wall Thickness | 2.0mm – 60mm | GB/T 5310, JIS G3454/5 | High/low pressure boilers |

| Length | 5.8m – 12m (customizable) | Customer spec | Power plants, chemical factories |

| Material Grades | 20G, 15Mo3, T12, SA210A1, 16MnG, etc. | ISO 9329, ASTM, EN | High/medium/low temp service |

| Delivery State | Normalized, tempered, annealed | ISO, ASME | All industrial boilers |

| Inspection | Ultrasound, X-ray, Hydrostatic test | ISO/GB/ASME | Safety-critical |

5. Data Visualization: Product Comparison & Material Grades

6. Supplier and Manufacturer Comparison: How to Choose the Right Partner?

| Supplier/Manufacturer | Certification | Lead Time | Customization | Global Supply |

|---|---|---|---|---|

| World Steel Material ISO 9001 | ISO, EN, ASME, API | 15-30 days | Yes | Yes |

| Sandvik (Europe) | ISO, PED, TÜV | 35-45 days | Limited | Yes |

| Sumitomo (Japan) | JIS, ISO | 40-60 days | Upon request | Yes |

| Baosteel (China) | API, EN, ISO | 30 days | Yes | Yes |

Key selection criteria when choosing boiler tube suppliers and seamless boiler tubes manufacturers include:

• Certifications (ISO 9001, API 5L, PED)—ensuring compliance and traceability.

• Lead time & logistics—affect project schedules, especially in EPC projects.

• Batch customization—ability to produce bespoke boiler steel pipe grades, wall thicknesses, length, and surface finish.

• Technical support & after-sales—long-term reliability.

World Steel Material has over 18 years in international boiler steel pipe supply, serving renowned EPC, power, and petrochemical clients in over 55 countries.

7. Customization Solutions: Tailor-Made Boiler Tube Systems

- Material Customization: Carbon, low alloy, and high alloy steel grades based on boiler operation conditions.

- Size Customization: Non-standard OD & wall, grooved/flanged/finned types.

- Coating & Surface: Zinc, paint, phosphate, and advanced anti-corrosion coatings for aggressive environments.

- Welding & Bending: Precision CNC forming for varied curvature and angles.

- Heat Treatment: Advanced normalizing/tempering processes to meet EN, ASME, and JIS performance criteria.

- Inspection & Third Party (SGS, BV): Optional independent testing for mission-critical applications.

8. Typical Application Scenarios: Experience & Case Study

Client: EPC Contractor for a leading waste-to-energy plant.

Solution: Custom seamless boiler steel pipe setup (20G+16MnG, 38x5.5mm, 420°C steam, coated for anti-corrosion).

Result: 18% increase in system efficiency, zero failures in 40,000+ hours, passed all third-party (SGS) and ISO 9001 audits.

Client: Power generation company.

Solution: EN 10216 T12 seamless boiler tubes (65x10mm), CNC bent U-shape, ANSI/ASME compliant.

Result: Reliable operation under 43MPa/560°C conditions for 5+ years, reduction in replacement costs by 25%.

- Worldwide usage in petrochemical plants, metallurgy, utilities, marine, and district heating systems.

- Advanced material selection (e.g., Mo-alloy) enables service in aggressive and cyclic load scenarios.

- Verified performance tracking through regular NDT, ultrasonic, and eddy current testing (as endorsed by ASME and ISO standards).

“Our plant runs continuously at close to peak design capacity with seamless boiler steel pipe provided by World Steel Material. Durability, weldability, and superior corrosion resistance led to a 22% decrease in operating costs.”—Plant Engineer, Oman LNG Project (2023, verified via client survey)

9. Frequently Asked Questions (FAQ) on Boiler Steel Pipes

10. Delivery, Certification & Support

- Lead time: 15–40 working days (based on order complexity/size)

- Production certification: ISO 9001, API 5L/5CT, CE mark, PED, EN10216, TUV, Bureau Veritas

- Third-party inspection: Supported for all supply batches

- Warranty: 12–24 months against defects in material or manufacture

- Customer support: 24/7 online assistance, documentation, installation, and after-sales service

- Flexible incoterms (FOB, CFR, DDP, etc.) and global on-site delivery

11. External References & Industry Insights

Industry experts highlight material advances and stricter inspection standards as crucial drivers of tube safety. For comprehensive technical discussions and best practices on seamless boiler tubes, refer to:

— International Journal of Pressure Vessels and Piping: https://www.journals.elsevier.com/international-journal-of-pressure-vessels-and-piping

— ASME Boiler & Pressure Vessel Code forums: https://www.eng-tips.com/threadminder.cfm?pid=803

Post time: 8 月 . 02, 2025 11:40