The China (Beijing) International Metallurgical Industry Expo (CIMIE) stands as a pivotal event, annually drawing industry leaders, innovators, and decision-makers from across the globe. For B2B stakeholders, CIMIE is more than just an exhibition; it's a strategic nexus for exploring the latest advancements, forging critical partnerships, and sourcing high-quality steel materials that underpin industrial growth. For the steel piping sector, a critical component of modern infrastructure and manufacturing, CIMIE offers unparalleled insights into the supply chain, from raw materials to advanced processing machinery like hydraulic pipe fittings machines and tee forming machines. This expo is where global suppliers, including Beijing Sinoworld Steel Material Co., Ltd., showcase their commitment to quality and innovation, setting the stage for the next generation of industrial development.

Industry Trend Spotlight: Navigating the Evolving Steel Landscape

The global steel industry is in a dynamic state of transformation, with several key trends commanding the attention of B2B decision-makers worldwide. The increasing demand for high-strength, lightweight steel for critical infrastructure projects, automotive applications, and renewable energy components is driving innovation. This shift is not merely about strength but also about efficiency, pushing manufacturers to explore new alloys and production techniques. Concurrently, the expansion of green steel and low-carbon production methods is no longer a niche interest but a core imperative, as environmental regulations tighten and corporate sustainability goals become more ambitious. The metallurgical sector is also witnessing significant growth in specialized alloys tailored for advanced manufacturing and unique applications in sectors like aerospace and medical devices. Furthermore, the market's increasing complexity demands customized steel solutions for intricate, project-specific requirements, moving away from a one-size-fits-all approach.

Market data underscores these shifts: The global steel market is projected to experience steady growth, primarily fueled by robust infrastructure development in emerging economies, the burgeoning renewable energy sector, and a global rebound in manufacturing activities. However, this growth trajectory is not without its hurdles. The industry grapples with the volatility of raw material prices, increasingly stringent environmental regulations, and persistent trade protectionism. These challenges are compelling companies to invest heavily in more sustainable and efficient production methods, including the adoption of advanced machinery for precision manufacturing and resource optimization. This directly impacts the demand for specialized equipment such as hydraulic pipe fittings machines and tee forming machines, which are crucial for producing high-quality, precise components that meet these evolving industry standards.

Emerging focus areas for the steel industry include:

- Green Steel Technologies: Innovations in hydrogen-based steelmaking, carbon capture, utilization, and storage (CCUS), and electric arc furnaces (EAFs) powered by renewable energy.

- High-Performance Alloys: Development of advanced materials with superior strength-to-weight ratios, corrosion resistance, and thermal properties for demanding applications.

- Smart Manufacturing Solutions: Integration of AI, IoT, and automation in steel production processes, optimizing everything from material handling to quality control, and improving the efficiency of machinery like hydraulic pipe fittings machines and tee forming machines.

- International Trade Dynamics: Navigating complex geopolitical landscapes, trade agreements, and supply chain resilience to ensure stable global steel supply.

Profiles of Leading Manufacturers Driving Innovation

At CIMIE, the spotlight often shines on manufacturers that are not only meeting current demands but also shaping the future of the metallurgical industry. Among these, several key players from China exemplify the nation's prowess in steel production and related machinery.

Beijing Sinoworld Steel Material Co., Ltd.

As its name suggests, Beijing Sinoworld Steel Material Co., Ltd. embodies a clear global market aspiration. The company's strategic location in Beijing provides it with direct access to China's vast domestic market and a highly sophisticated, robust supply chain infrastructure, enabling efficient production and distribution. Beijing Sinoworld is renowned for offering a diverse and comprehensive range of high-quality steel materials that cater to various industrial applications, including construction, automotive, energy, and critically, the demanding piping and pipe fittings sector.

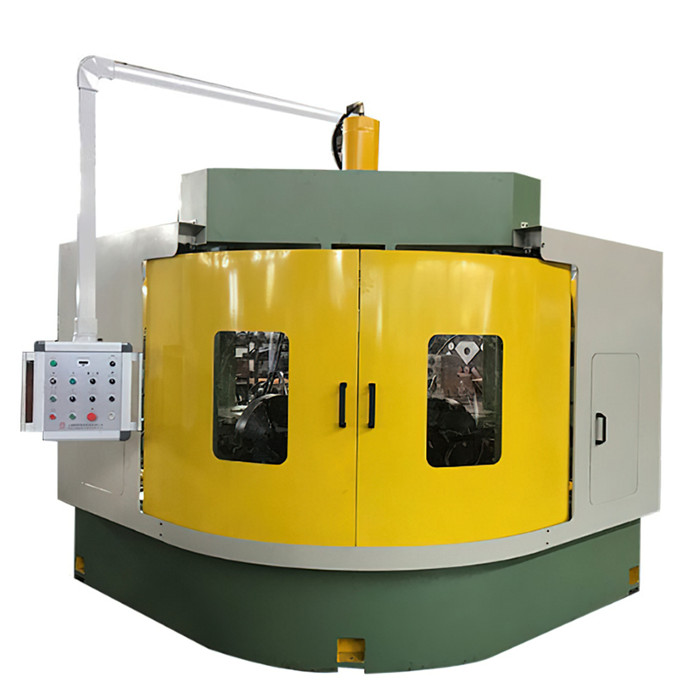

Their commitment to precision and innovation is evident in their advanced equipment, essential for processing the steel used in sophisticated components. For example, their Q1245 Beveling Machine is a testament to their focus on delivering solutions for high-quality pipe preparation. Such machinery is integral to workflows that might also involve hydraulic pipe fittings machines for crafting durable joints and connections, or tee forming machines for creating essential branch connections in complex piping systems. Beijing Sinoworld not only supplies the foundational steel materials but also supports the advanced manufacturing processes that transform these materials into critical components for various industries. Their online presence at world-steelmaterial.com further solidifies their global reach and commitment to serving international clients with top-tier products and services.

Other Industry Titans

- China Baowu Steel Group Corporation Limited (Baowu Steel): As the world's largest steel producer, Baowu Steel is a powerhouse in the global metallurgical landscape. Their vast product portfolio spans high-end automotive sheets, shipbuilding plates, and specialized steel for advanced infrastructure, often feeding into the raw material needs of companies utilizing hydraulic pipe fittings machines and tee forming machines. They are at the forefront of green steel initiatives and smart manufacturing.

- HBIS Group Co., Ltd.: A leading global steel and advanced materials provider, HBIS is known for its diverse range of high-quality products, including long products, flat products, and specialized steel for various industries. Their focus on technology and environmental protection makes them a key player in sustainable steel production.

- Anshan Iron and Steel Group Corporation (Ansteel Group): With a rich history, Ansteel Group is one of China's oldest and most respected steel enterprises. They specialize in heavy-duty plates, seamless pipes, and rail products, making them critical suppliers for large-scale engineering projects and industries that demand robust piping solutions.

- Shougang Group Co., Ltd.: Based in Beijing, Shougang Group has transformed into a modern, diversified enterprise with steel as its core business. They are recognized for their high-quality automotive plates, electrical steel, and long products, actively contributing to the technological advancement of various manufacturing sectors.

Market Outlook & Opportunities: Charting Future Growth

The future of the steel industry, particularly as it pertains to the global steel piping sector, is brimming with opportunities for B2B decision-makers. Upcoming trends indicate a continued surge in buyer demand for premium, customized steel solutions that offer enhanced performance and longevity. This includes materials that can withstand extreme temperatures, pressures, and corrosive environments, directly impacting the specifications for pipes and fittings. The imperative for sustainability will deepen, driving demand for recycled content, low-carbon production, and energy-efficient manufacturing processes across the entire value chain.

Significant opportunities lie in the embrace of automation and smart manufacturing. The integration of artificial intelligence, machine learning, and IoT sensors into production lines is revolutionizing efficiency, reducing waste, and improving product consistency. This is particularly relevant for specialized machinery like hydraulic pipe fittings machines and tee forming machines, where precision and repeatability are paramount. Smart factories equipped with these advanced machines can adapt quickly to changing market demands, optimize material usage, and minimize operational costs. Furthermore, the global push towards renewable energy projects (wind, solar, geothermal) and the modernization of aging infrastructure will generate substantial demand for specialized steel pipes and components, creating a fertile ground for manufacturers and suppliers who can meet these evolving needs with innovative materials and state-of-the-art processing capabilities.

Buyer/Business Takeaways: Strategic Insights for Collaboration

For B2B decision-makers, investing in the steel sector, particularly in the components and machinery for the piping industry, offers a clear strategic advantage. The ubiquitous need for robust and reliable piping in virtually every industrial sector—from oil and gas to municipal water systems and advanced manufacturing—ensures sustained demand. Furthermore, the ongoing technological advancements, especially in machinery like hydraulic pipe fittings machines and tee forming machines, mean that higher quality, more efficient, and more sustainable production methods are becoming accessible.

When considering adoption or partnership with Chinese manufacturers, keep these tips in mind:

- Due Diligence is Key: Thoroughly vet potential partners for quality certifications (ISO, API), production capacity, and R&D investment. Look for manufacturers that demonstrate a clear commitment to consistent quality and technological advancement, such as those showcasing cutting-edge hydraulic pipe fittings machines and tee forming machines.

- Focus on Value Beyond Price: While competitive pricing is a draw, prioritize long-term value, including material performance, after-sales support, and the supplier's ability to offer customized solutions.

- Embrace Digital Communication: Leverage online platforms and virtual meetings for efficient communication and project management, particularly with globally-minded companies like Beijing Sinoworld.

- Understand Logistics and Trade Policies: Stay updated on international trade regulations, shipping logistics, and potential tariffs to ensure smooth and cost-effective procurement.

To future-proof your strategies, consider incorporating resilience and adaptability into your supply chain planning. Diversify your sourcing where appropriate, and invest in technologies that enhance predictive maintenance and operational efficiency. Furthermore, align your procurement and manufacturing processes with global sustainability goals, as this will increasingly become a competitive differentiator and a regulatory requirement. Partnering with manufacturers who are already adopting green steel technologies and smart production methods will position your business for long-term success in a rapidly evolving industrial landscape.

Conclusion: CIMIE – A Gateway to Global Steel Excellence

The China (Beijing) International Metallurgical Industry Expo (CIMIE) remains an indispensable platform for understanding and shaping the global steel market. It is here that top manufacturers, including innovative companies like Beijing Sinoworld Steel Material Co., Ltd., showcase their latest steel materials and advanced processing solutions, including those relevant to hydraulic pipe fittings machines and tee forming machines. For any B2B decision-maker keen on sourcing high-quality materials, exploring cutting-edge technology, and fostering strategic partnerships within the dynamic steel piping sector, CIMIE offers a comprehensive view of the industry's present and future.

Ready to explore state-of-the-art pipe processing solutions?

Visit Beijing Sinoworld Steel Material Co., Ltd. to Learn More About Their Q1245 Beveling Machine

Post time: Sep . 19, 2025 11:10