Cold Forming Elbow Machine: What Matters in 2025 (Insider Notes)

If you’re sizing up an elbow cold forming machine for carbon or stainless fittings, here’s the quick reality: buyers want repeatable geometry, low wall thinning, and fewer scrap elbows. To be honest, the best lines I’ve seen combine conservative hydraulics with decent PLC logic—nothing too clever, just reliable.

Market Trends: Why Cold Forming Keeps Winning

Energy and district heating projects are still expanding, but EPCs push for lower embodied carbon. Cold forming saves energy versus hot push-bending, and the dimensional control is better—surprisingly so on thin-wall SS. Many customers say their scrap rates dropped from ~7% to below 2% after switching. There’s also a quiet shift to automated tool change and smarter force curves (servo-assisted hydraulics).

How It Works (Process Flow)

- Materials: CS (ASTM A234 WPB), SS (304/316), alloy steels; cut pipes per ASME B16.9 geometry.

- Prep: Deburr, lube (moly or polymer), fixture in die set with mandrel and clamp rings.

- Forming: Hydraulic ram drives the cold forming cycle; PLC controls pressure/time to limit wall thinning.

- Sizing: Final pass for ovality; eject and cool. No scale, minimal clean-up.

- Testing: Dimensions per ASME B16.9/EN 10253; hardness drift check; optional UT/MT on critical lines; hydro test by project spec (often B31.3 context).

- Finishing: Bevel per ASME/ISO; PMI on stainless lots; traceability label and heat number.

Typical acceptance data I see: wall thinning ≤ 10–12% (DN50–DN300), ovality ≤ 1.5%, ΔHB ≤ 20, surface Ra ≈ 3.2 μm after sizing. Real-world use may vary with die condition and operator habits.

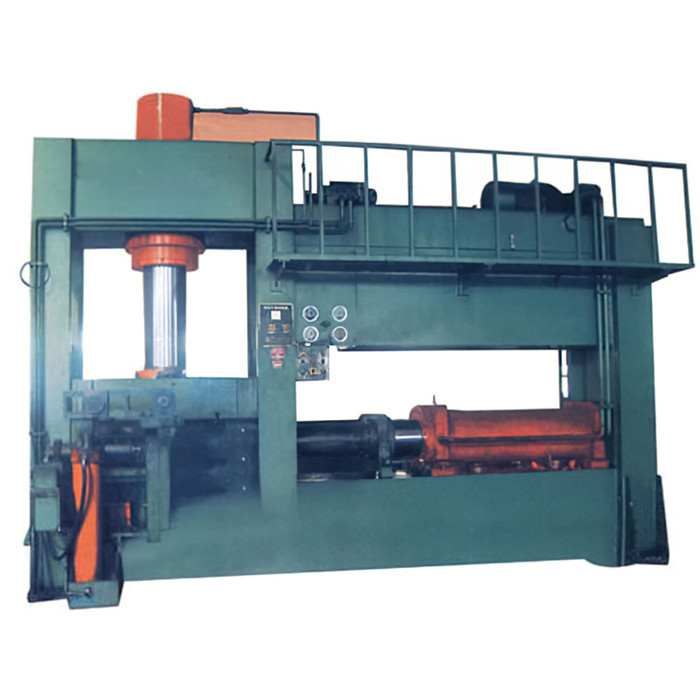

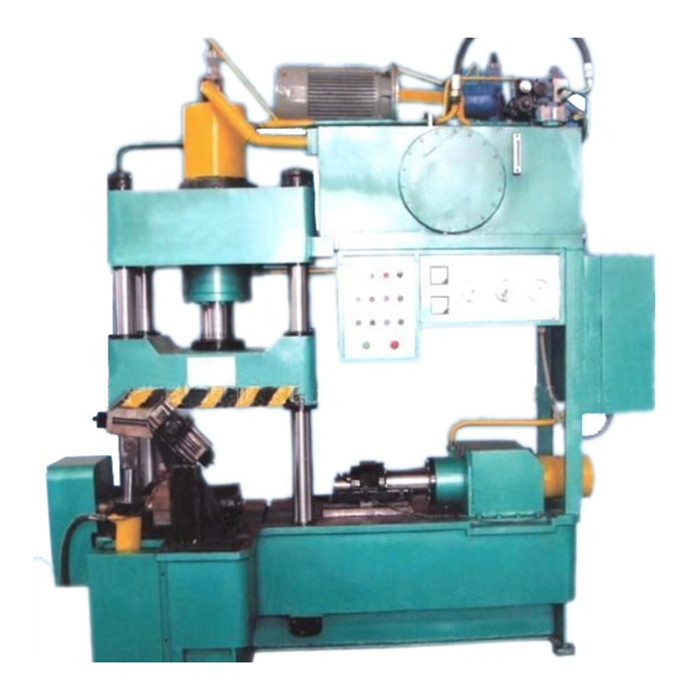

Key Specs (Cold Forming Elbow Machine)

| Type | Hydraulic cold forming (New) |

| Materials | CS / SS / Alloy stainless |

| Voltage / Power | 380V, 30 kW |

| Dimensions (L×W×H) | 5800 × 3200 × 4700 mm |

| Weight | ≈ 2500 kg |

| Elbow range | Commonly DN25–DN350 (project-specific) |

| Control | PLC with programmable pressure/time curves |

| Service life | Frame 10–15 yrs; die sets ≈ 20–60k cycles (depends on alloy) |

Origin: Rm 1103, Shangpintaihu Bld 3#, Tongzhou District, Beijing. It’s a tidy shop floor—saw it once; good spare parts room.

Applications, Advantages, Certifications

- Industries: Oil & gas, chemical, power plants, shipbuilding, fire protection, district heating.

- Advantages: Lower energy vs hot forming, clean surface, tighter ovality, less rework; safer for thin-wall SS.

- Certs & standards alignment: ISO 9001 QMS, ASME B16.9 dimensions, EN 10253 geometry, materials per ASTM/EN; CE on request.

Many customers report faster NDT pass rates after switching to a elbow cold forming machine due to consistent wall distribution.

Vendor Snapshot: What to Compare

| Vendor | Certs | Lead Time | After‑sales | Notes |

|---|---|---|---|---|

| World Steel Material | ISO 9001; CE (on request) | ≈ 35–55 days | Remote + on‑site, good spares | Balanced price/performance |

| Regional Supplier A | ISO 9001 | 20–30 days | Limited on‑site | Lower cost, fewer options |

| EU Builder B | ISO 9001/14001, CE | 60–90 days | Strong on‑site SLA | Top-tier price |

Customization & Real-World Cases

Options I’d ask for: die radius sets (1D/1.5D/2D), quick-change tooling, 415V or 440V electrics, CE wiring, and data logging. One LNG fabricator told us their elbow cold forming machine cut rework by 40% after switching to a gentler force curve; another district heating shop shaved two operators from the line with auto-lube and part ejection.

Buyer's Checklist

- Die wear rate and replacement cost (ask for cycle test data).

- Wall thinning on your worst-case spec (e.g., 316L thin-wall).

- Cert package and FAT protocol aligned to ASME B16.9/EN 10253.

- Spare parts lead time and remote diagnostics.

Citations

- ASME B16.9 – Factory-Made Wrought Buttwelding Fittings.

- EN 10253-2 – Butt-welding pipe fittings of steel for pressure purposes.

- ASTM A234/A234M – Carbon and Alloy Steel Pipe Fittings.

- ISO 9001:2015 – Quality management systems requirements.

- ASME B31.3 – Process Piping (testing guidance context).

Post time: Oct . 16, 2025 12:30