The Critical Role and Evolving Landscape of Well Casing Pipes

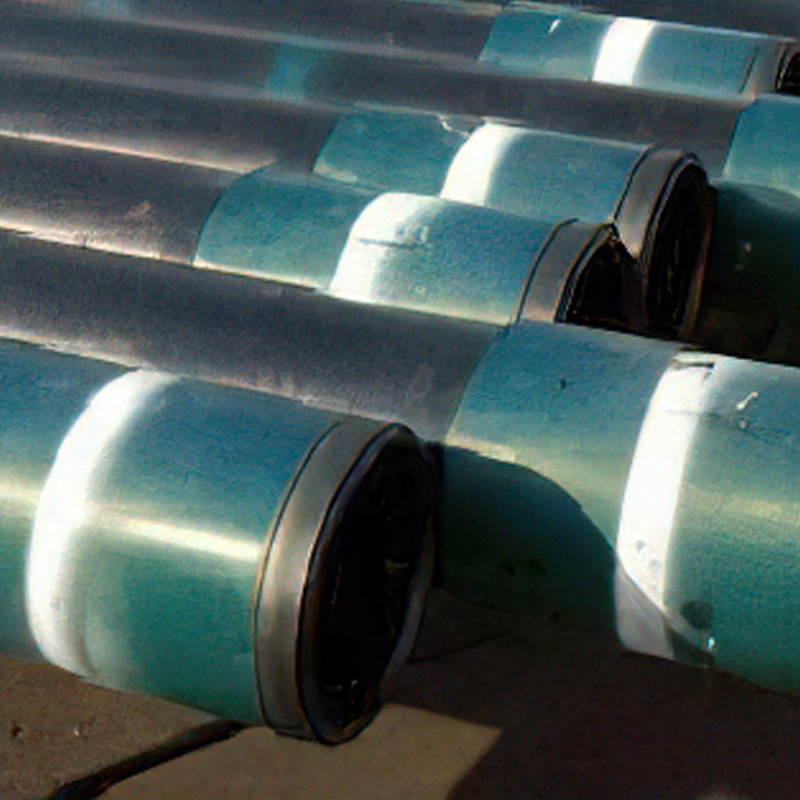

In the intricate world of resource extraction and civil engineering, the integrity and longevity of a well are fundamentally reliant on the quality of its casing. As global demand for energy and clean water continues its upward trajectory, the importance of robust and reliable well casing pipe for sale has never been more pronounced. This indispensable component forms the structural backbone of boreholes, preventing collapse, isolating different fluid-bearing formations, and providing a conduit for hydrocarbon or water extraction. The market for API 5CT L80/N80/J55/K55 BTC Casing and Tubing Pipe is witnessing significant innovation, driven by the need for enhanced performance in increasingly challenging drilling environments, including ultra-deep wells, horizontal drilling, and highly corrosive formations. Industry trends indicate a sustained demand for premium grade `casing pipe` that can withstand extreme pressures, temperatures, and chemical exposure, alongside a growing focus on environmental safety and operational efficiency. Furthermore, the selection of appropriate `casing pipe for borewell` applications, particularly in agricultural and municipal water supply projects, is crucial for long-term sustainability and preventing aquifer contamination. Our comprehensive approach ensures that every segment of the supply chain, from raw material sourcing to final delivery, adheres to the most stringent quality protocols. This commitment to excellence translates into superior products that meet, and often exceed, the rigorous demands of modern drilling operations, providing unparalleled reliability and operational cost-effectiveness. The continuous evolution in material science and manufacturing precision is reshaping expectations for what `casing pipe for sale` can achieve, allowing for deeper and more complex well designs while mitigating operational risks. Our offerings are meticulously engineered to provide maximum downhole integrity, minimizing downtime and optimizing resource recovery in diverse geological settings.

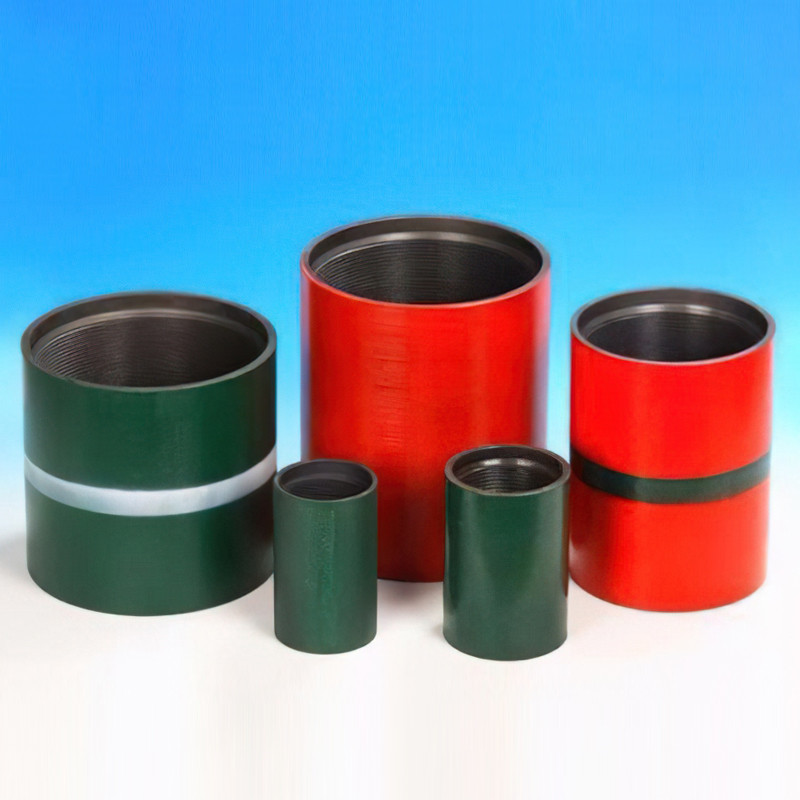

The technical specifications of well casing are paramount, dictating its suitability for specific well conditions. Grades like J55 and K55 are widely used for surface and intermediate casing in conventional wells, offering a balance of strength and cost-effectiveness. For more demanding applications, N80 and L80 grades, with their higher yield strength and tensile properties, become essential. These premium grades are often subjected to specialized heat treatments like quenching and tempering to achieve the desired mechanical properties and resistance to sulfide stress cracking (SSC), which is critical in sour gas environments. The Buttress Threaded Coupling (BTC) connection, a standard feature of our API 5CT casing, is renowned for its high joint strength and excellent sealing capabilities, ensuring reliable performance under severe axial loads and internal pressures. The careful selection of wall thickness, outer diameter (OD), and steel grade—such as a specific `5 1 2 casing pipe for sale` configuration—is critical to prevent collapse, burst, and tension failures throughout the well's lifespan. Our extensive experience in the B2B sector has equipped us with profound insights into the varied requirements of global drilling projects, enabling us to provide tailored solutions. We understand that each well presents its own unique set of challenges, from geological complexities to environmental sensitivities, which is why our advisory services extend beyond mere product supply to include comprehensive technical support. This holistic approach empowers our clients to make informed decisions, ensuring the optimal performance and safety of their drilling operations. The detailed understanding of stress distribution, corrosion mechanisms, and material fatigue is integrated into every stage of our product design and manufacturing, culminating in a product that delivers exceptional value and minimizes long-term operational costs.

Precision Manufacturing: Crafting Superior Well Casing Pipes

The manufacturing process for high-quality well casing pipe for sale is a testament to precision engineering and stringent quality control, designed to meet the exacting standards of API 5CT. It begins with the selection of premium steel billets, which are typically seamless for superior strength and uniformity, though high-frequency welded (HFW) pipes also meet specific API standards. The raw billets undergo a series of heating, piercing, rolling, and sizing operations to form the seamless pipe body. For grades like L80 and N80, a crucial step involves heat treatment through quenching and tempering. Quenching involves rapidly cooling the heated pipe to achieve a hard martensitic structure, followed by tempering, where the pipe is reheated to a specific temperature and then cooled to improve ductility and toughness, while retaining high strength. This meticulous thermal processing is vital for achieving the desired mechanical properties, including yield strength, tensile strength, and impact toughness, which are critical for the pipe's performance under downhole stresses. Furthermore, thread cutting, typically BTC (Buttress Threaded Coupling) as specified, is performed using advanced CNC machining to ensure precise dimensions and thread profiles, crucial for a secure and leak-proof connection. Each pipe then undergoes a battery of non-destructive evaluation (NDE) tests, including ultrasonic testing for internal and external flaws, electromagnetic inspection for longitudinal and transverse defects, and magnetic particle inspection for surface discontinuities. Hydrostatic pressure testing is also performed to verify the pipe’s integrity against burst and collapse pressures, confirming it meets API specifications and client requirements. These comprehensive quality checks at every stage ensure the production of reliable, high-performance casing pipe, significantly reducing the risk of failure during installation and operation.

Adherence to international standards such as ISO 9001 for quality management and API Q1 for quality programs in the petroleum and natural gas industry is not merely a formality but a foundational principle in our manufacturing ethos. This commitment is evidenced by our integrated quality control system that monitors everything from raw material composition using spectrographic analysis to the final dimensional inspection and pipe coating application. Each batch of casing pipe for sale is traceable through its unique serial number, linking it back to specific heat treatment records, mechanical test reports, and non-destructive examination results. This traceability provides an unparalleled level of transparency and accountability, assuring clients of the product's origin and quality. Our manufacturing facilities incorporate cutting-edge technology, including automated pipe handling systems and sophisticated inspection equipment, minimizing human error and maximizing efficiency. The focus on continuous improvement in manufacturing processes, coupled with substantial investments in research and development, allows us to push the boundaries of performance for 5 1 2 casing pipe for sale and other specific dimensions. By continually optimizing our production lines and incorporating feedback from field operations, we ensure that our API 5CT L80/N80/J55/K55 BTC Casing and Tubing Pipe remains at the forefront of industry capabilities, providing solutions that are not only high-performing but also economically viable for long-term projects in oil and gas, geothermal, and water well drilling sectors.

Technical Parameters and Performance Data

Understanding the detailed technical parameters of well casing pipe for sale is crucial for ensuring optimal performance and safety in diverse drilling environments. API 5CT specifications provide a standardized framework, allowing engineers to select the appropriate grade and dimensions for specific downhole conditions. Key parameters include Outer Diameter (OD), Wall Thickness (WT), Length (Range 1, 2, 3), Thread Type (e.g., BTC, LTC, STC), and steel grade (J55, K55, N80, L80, etc.). Each grade possesses distinct mechanical properties, particularly minimum yield strength and tensile strength, which dictate its resistance to collapse and burst pressures. For instance, L80 and N80 are often chosen for deeper wells or those with potential for H2S corrosion due to their superior strength and controlled metallurgy for SSC resistance. The "BTC" in API 5CT L80/N80/J55/K55 BTC Casing and Tubing Pipe refers to Buttress Threaded Coupling, a robust connection type known for its high axial strength and leak resistance, making it suitable for applications where high tensile loads are anticipated. Our internal testing data consistently demonstrates that our products exceed API minimums, providing an additional margin of safety and reliability. For example, typical collapse pressures for a 7-inch, 23lb/ft, L80 casing might range from 7,000-8,000 psi, depending on design factors, significantly surpassing the requirements for many challenging wells. This meticulous attention to detail in material selection and processing ensures that our casing pipe delivers consistent, verifiable performance in the field, minimizing the risks associated with downhole component failure and maximizing operational uptime.

To further illustrate the capabilities of our casing pipe for sale, below is a table summarizing common specifications and their typical applications. This data serves as a guide for selecting the optimal well casing pipe for sale based on projected well conditions. It is important to note that actual performance can vary based on specific environmental factors and installation procedures, necessitating close collaboration with our technical experts for tailored solutions. The precise dimension of `5 1 2 casing pipe for sale` is a frequent inquiry for specific well designs, offering a balance of bore size and structural integrity. Our commitment to transparency and technical excellence means providing clients with comprehensive test reports, material certifications, and detailed performance curves upon request. This robust documentation, coupled with our adherence to international standards like ISO and ANSI for testing protocols, provides the authoritative assurance that B2B buyers require when making critical infrastructure investments. We also provide guidance on corrosion prevention and advanced coating options, extending the lifespan of the `casing pipe for borewell` in aggressive environments. Our proactive approach to quality management, from raw material inspection to final product verification, underscores our dedication to delivering only the highest caliber of API 5CT L80/N80/J55/K55 BTC Casing and Tubing Pipe, ensuring unparalleled reliability for your most demanding projects.

| OD (in) | Weight (lb/ft) | Grade | Min. Yield Strength (psi) | Min. Tensile Strength (psi) | Connection Type | Typical Application |

|---|---|---|---|---|---|---|

| 4.5 | 9.5 - 13.5 | J55/K55 | 55,000 - 75,000 | 75,000 - 95,000 | BTC/STC | Shallow wells, Water wells |

| 5.5 | 15 - 23 | J55/K55/N80 | 55,000 - 80,000 | 75,000 - 100,000 | BTC/LTC | Intermediate casing, Production casing |

| 7 | 20 - 32 | J55/K55/N80/L80 | 55,000 - 80,000 | 75,000 - 100,000 | BTC/LTC | Production casing, Deep wells |

| 9.625 | 36 - 53.5 | J55/K55/N80/L80 | 55,000 - 80,000 | 75,000 - 100,000 | BTC/LTC | Surface casing, Intermediate casing |

| 13.375 | 48 - 68 | J55/K55/N80 | 55,000 - 80,000 | 75,000 - 100,000 | BTC/STC | Surface casing, Conductor pipe |

Diverse Applications and Unmatched Performance Advantages

The versatility and robust performance of our API 5CT L80/N80/J55/K55 BTC Casing and Tubing Pipe make it an ideal choice for a wide array of applications across critical industries. In the oil and gas sector, these pipes serve as essential conduits for drilling and production, functioning as surface casing to prevent bore wall collapse, intermediate casing to isolate formations, and production casing to facilitate hydrocarbon extraction. Their ability to withstand extreme downhole conditions, including high pressures and temperatures up to 250°C (482°F) and corrosive fluids like H2S and CO2, is paramount. For example, in a recent deep-well project in the Permian Basin, our L80 well casing pipe for sale demonstrated exceptional resilience against high tensile loads and collapse pressures at depths exceeding 15,000 feet, contributing significantly to the project's success and operational continuity. Beyond hydrocarbons, our casing pipe for borewell applications is extensively utilized in water well drilling for municipal, agricultural, and industrial water supply, ensuring the purity and reliable flow of groundwater. The anti-corrosion properties and long service life of our pipes are particularly advantageous in these scenarios, preventing contamination and reducing maintenance costs over decades.

In the burgeoning geothermal industry, where wells often encounter highly corrosive brines and elevated temperatures, our specialized casing pipe grades provide the necessary durability and structural integrity. Similarly, in mining and geological exploration, our casing pipe for sale supports exploratory drilling, offering reliable support for core sampling and well monitoring. The technical advantages of our products extend beyond mere material strength; they encompass innovative design, meticulous manufacturing processes, and comprehensive quality assurance. The advanced threading of BTC connections ensures superior leak resistance and simplified installation, reducing rig time and associated operational expenses. The precisely controlled chemical composition and heat treatment processes contribute to enhanced ductility and toughness, which are critical in preventing brittle fracture under shock loading or seismic activity. Our commitment to delivering an exceptional product translates into significant cost savings over the well’s lifecycle due to reduced failures, minimal intervention requirements, and extended operational periods. This long-term value proposition is a key differentiator for our well casing pipe for sale in a competitive market, ensuring that clients receive not just a product, but a comprehensive solution optimized for longevity, efficiency, and safety across all applicable industries, from petrochemical to metallurgy and civil infrastructure projects.

Choosing Your Supplier: Expertise, Customization, and Trust

Selecting the right supplier for your well casing pipe for sale is a strategic decision that profoundly impacts project success, operational costs, and long-term well integrity. A reputable manufacturer differentiates itself through demonstrable expertise, comprehensive certifications, extensive service history, and a commitment to customer support. Our company embodies these qualities, holding key industry certifications such as API Q1 and ISO 9001, which attest to our rigorous quality management systems. With over two decades of experience in the steel material industry, including specialized focus on API 5CT L80/N80/J55/K55 BTC Casing and Tubing Pipe, we have cultivated an unparalleled understanding of market demands and technical complexities. Our collaboration with leading global drilling companies and national oil corporations underscores our authoritative standing in the industry. We provide verifiable third-party test reports, comprehensive material traceability, and detailed product specifications, ensuring complete transparency and peace of mind for our B2B clients. Unlike manufacturers focused solely on volume, we prioritize solution-oriented approaches, understanding that each drilling project presents unique challenges requiring bespoke solutions. This client-centric philosophy is what positions us as a preferred provider for complex and critical projects requiring high-performance `casing pipe`.

Customization is a cornerstone of our service offering, ensuring that our casing pipe for sale precisely matches your project's unique specifications. Whether it's specific lengths, specialized external coatings for enhanced corrosion resistance in aggressive environments, or tailored premium connections beyond standard BTC for extreme conditions, our engineering team works closely with clients to develop optimal solutions. For instance, if your project requires a non-standard `5 1 2 casing pipe for sale` configuration with particular anti-corrosion properties or a different grade, we have the capability to deliver. This adaptability is critical for projects operating in unique geological formations or under stringent environmental regulations, where off-the-shelf solutions may not suffice. Our technical support extends to pre-sale consultation, guiding you through grade selection, collapse and burst calculations, and thread design, ensuring that every aspect of the `casing pipe` specification is optimized for performance and cost-efficiency. Post-sale, our dedicated support team offers assistance with logistics, installation best practices, and troubleshooting, providing a seamless and reliable experience from order placement to well completion. This holistic approach to client engagement reinforces the trustworthiness of our brand, establishing long-term partnerships built on mutual success and uncompromising quality in every piece of well casing pipe for sale we deliver.

Assurance of Quality: Warranty, Delivery, and Customer Support

The procurement of well casing pipe for sale represents a significant investment, and ensuring the long-term reliability of this critical infrastructure requires robust quality assurance and unwavering customer support. Our commitment to trustworthiness is enshrined in our comprehensive quality control protocols, which involve independent third-party inspection agencies at various stages of manufacturing and pre-shipment. These inspections cover dimensional accuracy, material composition verification, mechanical property testing, and non-destructive examination, providing an impartial verification of product quality. For every batch of API 5CT L80/N80/J55/K55 BTC Casing and Tubing Pipe, clients receive detailed Mill Test Certificates (MTCs) that meticulously document chemical analysis, mechanical test results, and heat treatment records, ensuring full traceability back to the raw material. Our standard product warranty covers manufacturing defects and material non-conformance for a specified period, offering peace of mind and protecting your investment. This transparent approach, combined with our proven track record, establishes us as a highly authoritative and reliable source for high-performance `casing pipe`. We understand that the supply chain's efficiency is as vital as the product itself, which is why we meticulously manage logistics, ensuring timely and secure delivery of your `casing pipe for borewell` to any global destination, often adapting to complex logistical requirements for remote drilling sites.

Our dedication to customer satisfaction extends beyond product delivery, encompassing a robust after-sales support system. Our technical specialists are available to address any queries regarding product installation, operational parameters, or maintenance, ensuring seamless integration of our casing pipe for sale into your projects. We provide detailed guidance on best practices for handling, storage, and running of casing strings to prevent damage and optimize performance. For urgent requirements or complex issues, our rapid response team is equipped to provide timely and effective solutions, minimizing potential downtime and operational disruptions. The delivery schedule for 5 1 2 casing pipe for sale and other dimensions is meticulously planned and communicated, considering production lead times, shipping logistics, and customs clearances to ensure adherence to project timelines. In instances of unforeseen challenges, our proactive communication channels keep clients informed every step of the way. This unwavering commitment to excellence in both product quality and customer service reinforces the experience and trustworthiness we offer. By choosing us as your partner for API 5CT L80/N80/J55/K55 BTC Casing and Tubing Pipe, you are investing in a comprehensive solution backed by decades of industry leadership, unparalleled technical expertise, and a steadfast dedication to your project's success, guaranteeing the optimal performance of every well casing pipe for sale you acquire.

Frequently Asked Questions (FAQ)

-

Q: What does API 5CT signify for casing pipes?

A: API 5CT is a specification from the American Petroleum Institute that defines the technical delivery conditions for steel pipes (casing and tubing) used as casing or production tubing in wells. It covers grades, mechanical properties, chemical composition, and testing requirements, ensuring product quality and interchangeability across manufacturers. -

Q: How do J55, K55, N80, and L80 grades differ?

A: These are steel grades with increasing yield strength and tensile strength. J55 and K55 are common for less demanding applications. N80 offers higher strength for deeper wells. L80 is a premium grade with controlled sulfur content and specific heat treatment (quenched and tempered) to resist sulfide stress cracking (SSC) in sour gas environments, making it suitable for corrosive conditions. -

Q: What is BTC, and why is it important for well casing pipes?

A: BTC stands for Buttress Threaded Coupling. It is a type of connection used for casing pipes, characterized by its robust design, high joint strength, and excellent sealing capabilities. BTC connections are widely used due to their efficiency in handling high axial loads and internal pressures, ensuring the integrity of the casing string in demanding downhole conditions. -

Q: What are the typical delivery lead times for large orders of well casing pipe?

A: Delivery lead times vary depending on the specific grade, dimensions, order volume, and current production schedules. For standard API 5CT items, lead times typically range from 4-8 weeks from order confirmation. For custom specifications or very large quantities, more time may be required. We provide detailed lead time estimates with each quotation and maintain transparent communication throughout the order fulfillment process. -

Q: Can your well casing pipes be customized for specific project requirements, such as unique lengths or coatings?

A: Yes, absolutely. We specialize in providing customized solutions. We can manufacture pipes to specific lengths to minimize field cutting and waste. Additionally, we offer various internal and external coating options, such as anti-corrosion coatings (e.g., fusion-bonded epoxy, internal plastic coating) to enhance the lifespan and performance of the pipes in highly corrosive environments, tailored to your exact project needs.

Conclusion: Your Trusted Partner for Superior Casing Pipe Solutions

In summation, the selection and deployment of high-quality well casing pipe for sale are non-negotiable for the safety, efficiency, and longevity of any drilling operation. From the critical stages of exploration to the sustained efforts of production, the integrity of the casing string is the ultimate determinant of success. Our API 5CT L80/N80/J55/K55 BTC Casing and Tubing Pipe stands as a benchmark of excellence, meticulously engineered and rigorously tested to meet the most demanding specifications of the oil and gas, geothermal, and water well industries. Our expertise, underscored by decades of experience and adherence to global standards such as API and ISO, ensures that every piece of `casing pipe` we deliver provides unparalleled performance and reliability. By focusing on advanced manufacturing processes, comprehensive quality control, and client-centric customization, we provide solutions that not only meet but exceed technical requirements, contributing significantly to reduced operational risks and enhanced economic returns. Whether your project demands standard API grades or specialized solutions like `5 1 2 casing pipe for sale` for unique geological challenges, our commitment to innovation and customer satisfaction remains unwavering. We pride ourselves on being more than just a supplier; we are a strategic partner dedicated to empowering your projects with superior `casing pipe for sale` that guarantees durability, efficiency, and unwavering support throughout the entire lifecycle of your well.

References

- American Petroleum Institute. (2018). API Specification 5CT: Specification for Casing and Tubing. 10th Edition.

- International Organization for Standardization. (2015). ISO 9001:2015 - Quality management systems - Requirements.

- Dugstad, A. (2007). Localized corrosion in oil and gas production. NACE International Corrosion Conference and Expo.

- Adachi, Y., et al. (2014). Development of high collapse resistant casing for deep gas wells. Journal of Pressure Vessel Technology, 136(3), 031401.

- World Steel Association. (2023). Steel Statistical Yearbook.

Post time: Aug . 18, 2025 05:00