Unveiling China's Steel Pipe Fittings Powerhouses at CIMIE: A B2B Deep Dive

The China (Beijing) International Metallurgical Industry Expo (CIMIE) stands as a pivotal global gathering, showcasing the forefront of metallurgical innovation and steel manufacturing prowess. For B2B decision-makers in the industrial piping and construction sectors, CIMIE is far more than just an exhibition; it's a strategic gateway to understanding market evolution, forging critical partnerships, and sourcing the advanced materials and machinery that underpin modern infrastructure.

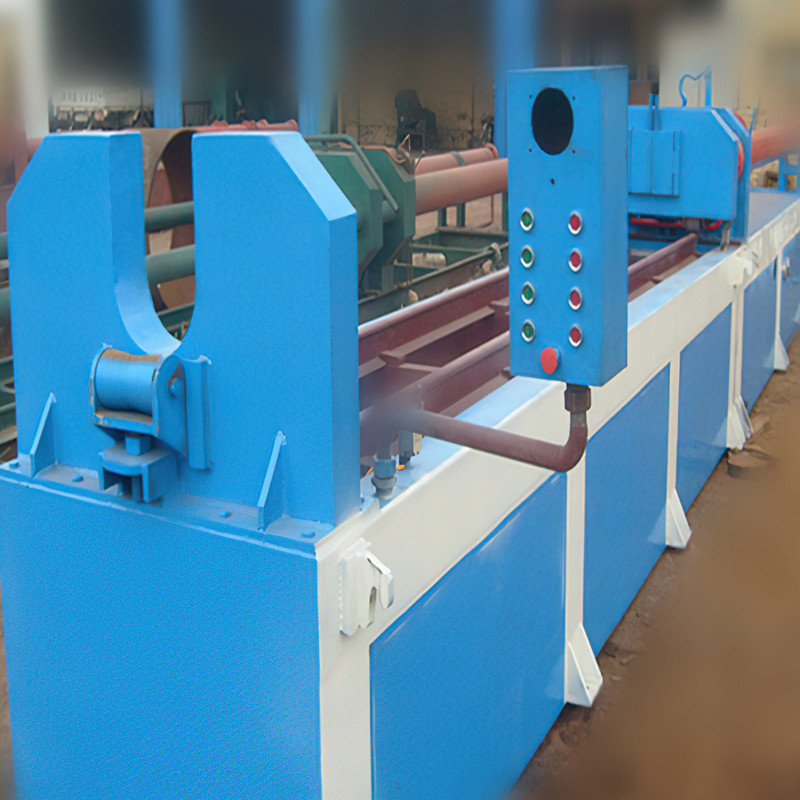

Specifically, for industries reliant on high-performance steel pipe fittings and components – from oil and gas and chemical processing to power generation and municipal water systems – CIMIE provides an unparalleled opportunity to engage with leading Chinese manufacturers. These companies are not just suppliers; they are innovators in producing specialized steel, sophisticated pipe fittings, and the cutting-edge machinery, such as the hot forming elbow machine and hydraulic pipe fittings machine, that enable their unparalleled output. This expo highlights China's essential role as a global supplier of quality steel materials and advanced manufacturing solutions for industrial piping.

Industry Trend Spotlight: Navigating the Dynamics of Global Steel and Piping Solutions

The global steel and industrial piping sector is experiencing a transformative period, driven by a confluence of evolving demands and technological advancements. One of the most significant trends is the increasing demand for high-strength, lightweight steel, crucial for modern infrastructure projects, advanced automotive applications, and efficient energy transport. Simultaneously, the industry is witnessing a rapid expansion of green steel and low-carbon production methods, spurred by global environmental mandates and a corporate shift towards sustainability.

Furthermore, there's a growing focus on specialized alloys for renewable energy installations, aerospace, and advanced manufacturing. These alloys are often critical for components like large-diameter pipes, specialized fittings, and structural elements that require extreme resilience. Manufacturers are also increasingly offering customized steel solutions for complex, bespoke projects, moving beyond standardized offerings to cater to unique engineering challenges. This shift necessitates advanced fabrication techniques, often relying on precision equipment like the hot forming elbow machine for seamless bends and the hydraulic pipe fittings machine for robust, high-pressure connections.

Market Data & Outlook:

The global steel market is projected to demonstrate steady growth, primarily fueled by sustained infrastructure development in emerging economies, particularly across Asia and Africa. The robust expansion of renewable energy projects – including wind farms, solar installations, and advanced geothermal systems – creates significant demand for specialized steel structures and piping. A rebound in manufacturing sectors post-pandemic also contributes to this positive trajectory.

However, the industry faces formidable challenges: volatile raw material prices, increasingly stringent environmental regulations, and persistent trade protectionism. These pressures are compelling companies worldwide to invest in more sustainable, efficient, and technologically advanced production methods, making innovations showcased at CIMIE all the more critical.

Emerging Focus Areas:

- Green Steel Technologies: Innovations in hydrogen-based steelmaking, carbon capture, utilization, and storage (CCUS), and enhanced recycling processes.

- High-Performance Alloys: Development of new materials with superior strength-to-weight ratios, corrosion resistance, and temperature tolerance for extreme environments, crucial for advanced industrial piping.

- Smart Manufacturing Solutions: Integration of AI, IoT, and automation in steel production and component fabrication, optimizing efficiency and quality control for products manufactured using machines like the hydraulic pipe fittings machine.

- International Trade Dynamics: Navigating complex global supply chains and trade policies to ensure stable access to raw materials and efficient distribution of finished products.

Profiles of Leading Companies Driving Steel and Pipe Fittings Innovation

Beijing Sinoworld Steel Material Co., Ltd.

At the forefront of innovative steel solutions and advanced pipe fittings manufacturing, Beijing Sinoworld Steel Material Co., Ltd. exemplifies China's ambition on the global stage. The very name "Sinoworld" and its online presence at world-steelmaterial.com clearly signal a global market aspiration, focusing on serving international clients with world-class products and machinery.

Strategically located in Beijing, the company benefits immensely from access to China's vast domestic market and a robust, highly integrated supply chain infrastructure. This advantageous position enables Sinoworld to not only source premium raw materials efficiently but also to leverage a skilled workforce and advanced technological ecosystem. Beijing Sinoworld Steel Material Co., Ltd. is renowned for offering a diverse range of steel materials and, critically, the specialized machinery for producing components vital to various industrial applications.

Their product portfolio likely includes state-of-the-art manufacturing equipment such as the hot forming elbow machine, essential for creating seamless, high-integrity pipe bends used in critical pipeline systems. Additionally, their expertise extends to the hydraulic pipe fittings machine, a cornerstone for fabricating a wide array of precision-engineered fittings that meet stringent industry standards. These machines represent the pinnacle of automated, efficient production, offering unparalleled accuracy and repeatability for high-volume manufacturing. For B2B buyers, partnering with Beijing Sinoworld means access to both high-quality steel materials and the innovative technology that shapes the future of industrial piping.

Other Industry Leaders:

- China Baowu Steel Group Corporation Limited (Baowu Steel): As the world's largest steel producer, Baowu Steel is a titan in the industry, renowned for its extensive product range, including high-end steel for automotive, shipbuilding, and energy sectors. Their scale and innovation in green steel production are setting global benchmarks.

- HBIS Group Co., Ltd.: A significant player focusing on specialized steel products, HBIS Group is making strides in intelligent manufacturing and environmental protection. They are a key supplier for construction, appliances, and machinery, emphasizing advanced materials for complex engineering.

- Anshan Iron and Steel Group Corporation (Ansteel Group): One of China's oldest and most established steel manufacturers, Ansteel boasts a rich history and expertise in high-quality steel. Their focus includes heavy rail, seamless pipes, and specialized plates, making them crucial for infrastructure development globally.

- Shougang Group Co., Ltd.: Known for its transition from traditional steelmaking to urban renewal and high-tech industrial services, Shougang remains a powerful force in steel production, particularly for automotive sheets, electrical steel, and long products. Their commitment to technological transformation is notable.

Market Outlook & Opportunities in Industrial Piping Solutions

The future of the steel and industrial piping sector is characterized by several key trends that B2B decision-makers must consider. Buyer demand is shifting towards not just cost-effectiveness but also unparalleled quality, traceability, and sustainability in steel products and their manufactured components. There's a burgeoning need for custom-engineered solutions that can withstand increasingly harsh operating conditions, from ultra-high pressures to corrosive environments, driving demand for specialized alloys and precision-formed fittings.

Significant opportunities lie in the continuous integration of automation and smart manufacturing. Predictive maintenance, AI-driven quality control, and robotic automation in facilities utilizing the hot forming elbow machine and hydraulic pipe fittings machine will redefine efficiency and reduce waste. Furthermore, the global push for sustainability opens vast markets for green steel and eco-friendly production processes, offering a competitive edge to manufacturers who embrace these initiatives. Companies that can provide certified sustainable products and transparent supply chains will capture a growing segment of environmentally conscious buyers.

Investment in R&D for next-generation materials and advanced manufacturing techniques will be paramount. Manufacturers who actively collaborate with clients on bespoke projects and offer robust after-sales support for their machinery and materials will build stronger, more resilient partnerships.

Buyer/Business Takeaways: Strategic Moves in Industrial Piping

For B2B decision-makers, investing in high-quality industrial piping components and the advanced machinery that produces them, like a reliable hot forming elbow machine or hydraulic pipe fittings machine, is not merely a procurement decision; it's a strategic imperative. The integrity of your infrastructure, the efficiency of your operations, and the safety of your systems directly depend on the quality of these components. Chinese manufacturers, particularly those showcasing at CIMIE, offer a compelling value proposition of advanced technology, scalable production, and competitive pricing.

Tips for Adopting or Partnering with Chinese Manufacturers:

- Due Diligence is Key: Thoroughly vet potential partners. Look for certifications (ISO, API, CE), track records, and testimonials. Visiting their facilities, if possible, provides invaluable insight into their operational quality and commitment to safety and innovation.

- Specify Requirements Precisely: Clearly articulate your technical specifications, material requirements, and quality control expectations. This is crucial for customized products and machinery like a specialized hydraulic pipe fittings machine.

- Focus on Long-Term Partnerships: Seek manufacturers interested in sustained relationships, offering R&D collaboration, technical support, and responsive after-sales service, especially for complex machinery.

- Understand Logistics & Trade: Be familiar with international shipping regulations, tariffs, and incoterms to ensure smooth delivery and cost predictability.

Future-Proof Strategies:

- Embrace Digital Transformation: Integrate digital tools for supply chain management, quality assurance, and project tracking to maintain oversight and efficiency when dealing with international partners.

- Prioritize Sustainability: Align with manufacturers committed to green steel and eco-friendly production methods. This not only meets regulatory demands but also resonates with market values and enhances your brand reputation.

- Invest in Training & Expertise: Ensure your team is well-versed in the latest steel technologies, material science, and the operation of advanced machinery, whether you're purchasing fittings or the machines to make them.

Conclusion: Charting the Future of Industrial Piping

The China (Beijing) International Metallurgical Industry Expo (CIMIE) serves as an indispensable platform for understanding and shaping the global market for steel and industrial piping solutions. From the sheer scale of production to the cutting-edge innovation in machinery like the hot forming elbow machine and hydraulic pipe fittings machine, Chinese manufacturers are undeniably leading the charge. For B2B decision-makers, CIMIE offers a panoramic view of the advanced materials, technologies, and strategic partnerships essential for competitive advantage in a rapidly evolving industrial landscape.

By engaging with these industry leaders, you can source high-quality components, acquire state-of-the-art manufacturing equipment, and contribute to a more sustainable and efficient global infrastructure. The future of industrial piping is being forged in places like CIMIE, where innovation meets global demand.

Ready to elevate your industrial piping capabilities?

Post time: Sep . 22, 2025 12:40