Introduction to Hot-Dipped Galvanized Steel Pipes

In the realm of industrial infrastructure and construction, the demand for durable, corrosion-resistant piping solutions is paramount. Among the leading choices, bulk galvanized pipe stands out as a superior material, offering extended service life and reliability in challenging environments. Galvanization, specifically hot-dipping, involves coating steel pipes with a layer of zinc, providing a robust barrier against rust and corrosion. This process is critical for applications requiring long-term structural integrity and minimal maintenance, making it an indispensable component across various sectors from petrochemical to water treatment.

This comprehensive overview delves into the intricate aspects of galvanized steel pipes, covering their manufacturing processes, technical specifications, diverse applications, and inherent advantages. We will also explore industry trends, crucial vendor selection criteria, and the possibilities of customized solutions, fortified by real-world case studies and data-driven insights to ensure our content meets the highest standards of expertise, authoritativeness, and trustworthiness for B2B decision-makers and engineering professionals.

Industry Landscape and Emerging Trends in Galvanized Piping

The global market for galvanized pipes is experiencing steady growth, driven by increasing infrastructure development, urbanization, and the need for durable piping in industrial applications. Industry reports indicate a compound annual growth rate (CAGR) of approximately 4-6% for the galvanized steel market, projected to reach significant valuations by the end of the decade. This expansion is fueled by several key trends:

- Infrastructure Investment: Governments worldwide are investing heavily in water treatment plants, urban drainage systems, and public utility networks, where the longevity and corrosion resistance of bulk galvanized pipe are critical.

- Sustainability and Lifecycle Cost: There's a growing emphasis on materials with longer service lives and lower environmental impact over their entire lifecycle. Galvanized steel, with its impressive durability (often exceeding 50 years in benign environments), aligns perfectly with these sustainability goals.

- Technological Advancements: Innovations in galvanizing techniques, such as continuous galvanizing lines and improved zinc alloy coatings, are enhancing the performance and cost-effectiveness of these pipes. Furthermore, advancements in quality control and inspection methods ensure stricter adherence to international standards.

- Diversification of Applications: Beyond traditional uses, galvanized pipes are finding new niches in renewable energy installations, agricultural irrigation, and modular construction, showcasing their versatility and adaptability.

These trends underscore the enduring relevance and strategic importance of galvanized piping solutions in modern industrial and urban development.

Manufacturing Process: From Raw Steel to Bulk Galvanized Pipe

The production of hot-dipped galvanized steel pipes is a meticulously controlled multi-stage process designed to ensure a uniform, durable, and protective zinc coating. The primary material is high-quality carbon steel, often conforming to ASTM A53, EN 10255, or similar specifications for seamless or welded steel pipes (e.g., ERW, spiral welded). Each step is critical for the final product's performance and longevity.

Process Flow Steps:

- Raw Material Inspection: Incoming steel pipes (black pipes) are inspected for defects, dimensions, and material composition to ensure they meet specified standards.

- Degreasing/Cleaning: Pipes are immersed in an alkaline cleaning solution to remove oil, grease, dirt, and other organic contaminants that would interfere with zinc adhesion. This typically involves several tanks with rinsing stages.

- Pickling: The cleaned pipes are then submerged in an acidic solution, commonly hydrochloric acid (HCl) or sulfuric acid (H2SO4), to remove mill scale, rust, and other inorganic surface impurities. This creates a chemically clean, active steel surface for galvanizing.

- Rinsing: After pickling, pipes are thoroughly rinsed in water to remove residual acid and dissolved iron salts, preventing contamination of the fluxing solution.

- Fluxing: Pipes are immersed in a flux solution, typically zinc ammonium chloride, which cleans any oxides that may have formed after pickling and promotes wetting of the steel surface by the molten zinc, ensuring proper adhesion. The flux also prevents further oxidation before galvanizing.

- Hot-Dip Galvanizing: This is the core process. The fluxed pipes are totally immersed in a bath of molten zinc, maintained at approximately 450°C (840°F). During immersion, the molten zinc metallurgically bonds with the steel, forming a series of iron-zinc alloy layers, topped by a pure zinc layer. This creates the characteristic corrosion-resistant coating. Immersion time varies based on pipe size and desired coating thickness, often ranging from minutes to hours.

- Cooling: After removal from the zinc bath, the pipes are cooled, typically by air or water quenching. This solidifies the zinc coating.

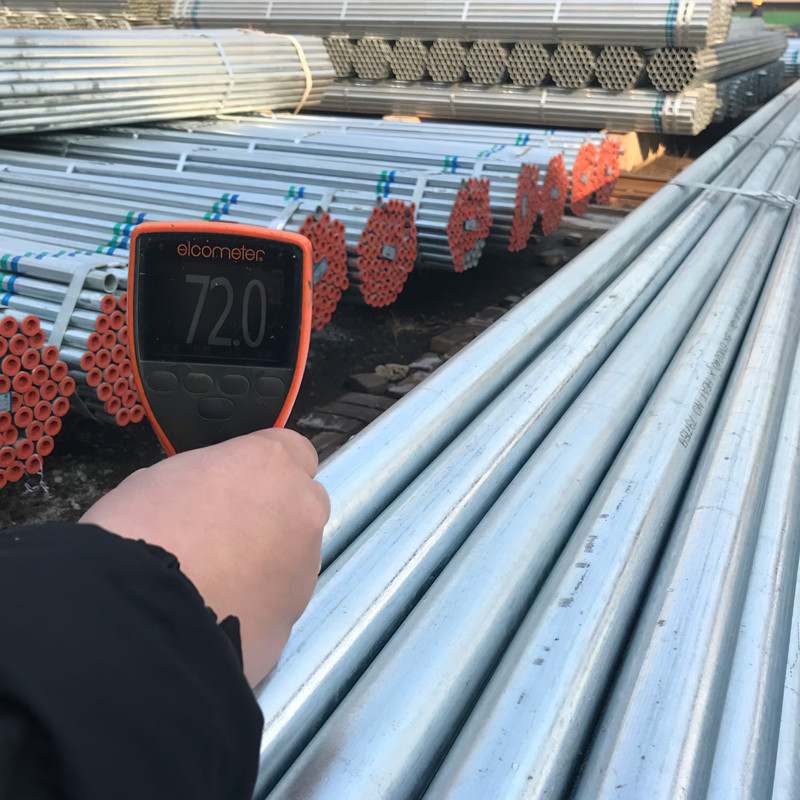

- Finishing and Inspection: Excess zinc is removed, and the pipes undergo thorough inspection. This includes visual inspection for coating uniformity, thickness measurement (e.g., using magnetic gauges, conforming to ISO 1461, ASTM A123), adhesion tests (e.g., hammer test), and sometimes destructive tests like bending or cutting. Threads and couplings are also inspected.

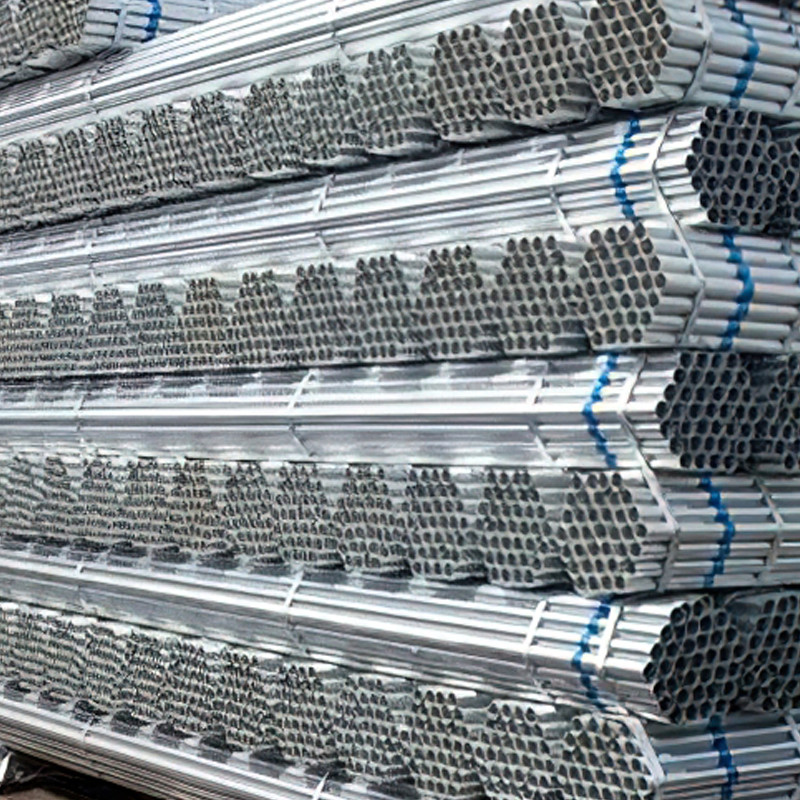

- Packaging: Finished pipes are bundled, marked, and prepared for shipping.

This meticulous manufacturing sequence ensures that each bulk galvanized pipe meets stringent quality and performance criteria, delivering a service life often exceeding 50 years in typical atmospheric conditions. Target industries for these pipes include petrochemical, metallurgy, water supply & drainage, construction, and power generation. The advantages demonstrated in typical application scenarios include superior energy saving by reducing maintenance and replacement needs, and unparalleled corrosion resistance, particularly against external environmental factors.

Technical Specifications and Parameters of Bulk Galvanized Pipe

Understanding the precise technical specifications is crucial for engineers and project managers to select the correct bulk galvanized pipe for their applications. These parameters dictate the pipe's suitability for specific pressures, temperatures, and corrosive environments. Our galvanized pipes adhere to leading international standards, ensuring consistent quality and performance.

Typical Product Specification Table: Galvanized Steel Pipes (Hot-Dipped)

The galvanized pipe types we offer cater to diverse project needs, from light-gauge structural applications to heavy-duty fluid conveyance systems. These specifications are critical in ensuring compatibility and optimal performance within complex engineering systems.

Diverse Galvanized Pipe Types and Their Applications

Beyond the general category, there are several distinct galvanized pipe types, each optimized for specific applications and performance requirements. Understanding these variations is essential for proper material selection:

- Hot-Dipped Galvanized Steel Pipes: As detailed, these are the most common, featuring a thick, durable zinc coating formed through immersion in molten zinc. They offer superior corrosion resistance and longevity. Widely used for water transmission, sewage, fire suppression, and structural supports.

- Electro-Galvanized Pipes: These pipes have a thinner zinc coating applied through an electroplating process. While offering some corrosion protection, they are less robust than hot-dipped versions and typically used in less aggressive environments, such as interior structural elements or conduit for electrical wiring. The focus here is on galvanized tubing for lighter-duty applications.

- Pre-Galvanized Pipes: Also known as mill-galvanized, these pipes are made from steel sheets or coils that have been galvanized before being formed into pipes. The welding seam is often coated post-formation, but the overall coating can be less uniform than hot-dipped pipes. They are cost-effective for applications where severe corrosion is not the primary concern.

- Threaded Galvanized Pipes: These are hot-dipped galvanized pipes with threaded ends, designed for easy assembly with threaded fittings. They are prevalent in residential and commercial plumbing, as well as various industrial fluid transfer systems.

- Grooved Galvanized Pipes: Featuring grooves at their ends, these pipes are used with mechanical couplings, providing quick installation and flexibility, especially in fire protection systems and large-scale industrial fluid lines.

Each type offers a distinct balance of cost, corrosion resistance, and ease of installation, making them suitable for a wide array of projects. Our expertise lies in guiding clients to the optimal choice based on their specific operational and environmental parameters.

Key Application Scenarios for Galvanized Pipe

The versatility and robust nature of galvanized pipe make it a preferred choice across numerous demanding industries. Its ability to withstand harsh conditions, combined with a long service life, translates into significant cost savings and enhanced operational reliability.

- Water Supply and Drainage Systems: Galvanized pipes are extensively used in both potable water distribution and wastewater management. The zinc coating prevents internal corrosion, ensuring clean water delivery and preventing pipe degradation in drainage networks. This application benefits immensely from the enhanced durability of galvanized pipe.

- Petrochemical and Oil & Gas Industries: In these sectors, pipes are exposed to corrosive chemicals, fluctuating temperatures, and extreme pressures. Galvanized pipes are often specified for non-critical process lines, utility lines, and structural components where protection against atmospheric and minor chemical corrosion is essential.

- Construction and Structural Applications: For scaffolding, fencing, railings, and structural supports, galvanized pipes provide strength and weather resistance without the need for constant painting or maintenance. This ensures the structural integrity and aesthetic appeal of constructions over decades.

- Fire Protection Systems: Due to their reliability and resistance to internal corrosion, galvanized steel pipes are a common choice for sprinkler systems and fire hydrants, where system integrity is paramount.

- Agriculture: In irrigation systems, greenhouses, and livestock enclosures, galvanized pipes offer a durable and hygienic solution, resisting rust from moisture and chemicals in fertilizers or animal waste.

- General Engineering and Manufacturing: Used in diverse applications from machine frames to exhaust systems and protective conduits.

Unrivaled Technical Advantages of Galvanized Pipe

The adoption of galvanized pipes in critical infrastructure projects is not arbitrary; it's a strategic decision based on a compelling array of technical advantages that directly impact project lifecycle costs, safety, and operational efficiency.

- Superior Corrosion Resistance: The primary advantage is the dual protection offered by the zinc coating. It acts as a physical barrier and provides cathodic (sacrificial) protection. If the zinc coating is scratched, the surrounding zinc corrodes preferentially, protecting the exposed steel, preventing rust migration, and extending the pipe's service life significantly beyond that of unprotected steel.

- Extended Service Life & Cost-Effectiveness: With a typical lifespan of 20-50+ years, galvanized pipes drastically reduce the frequency of maintenance, repair, and replacement. This translates into substantial long-term cost savings, a critical factor for large-scale industrial and municipal projects. The initial investment is offset many times over by reduced operational expenditure.

- Enhanced Strength and Durability: The galvanizing process does not compromise the inherent strength of the steel pipe. It retains the high tensile strength and structural integrity of steel while gaining a protective exterior, making it resistant to mechanical damage during handling, installation, and operation.

- Ease of Inspection: The integrity of a galvanized coating can be visually inspected and verified with simple, non-destructive thickness gauges, ensuring quality control is straightforward and efficient.

- Versatility: Suitable for a vast range of environments, from marine and industrial atmospheres to underground installations, without needing further surface treatments.

- Environmentally Friendly: Zinc is a natural and recyclable material. The longevity of galvanized products contributes to sustainability by reducing material consumption and waste generation.

These advantages collectively position galvanized pipe as a leading material for sustainable, resilient, and economically viable infrastructure development.

Strategic Vendor Comparison for Galvanized Pipe Wholesale

When procuring galvanized pipe wholesale, selecting the right vendor is as critical as selecting the right product. A strategic partner can significantly impact project timelines, budget, and the ultimate success of an installation. Here are key criteria for evaluating potential suppliers:

- Quality Assurance and Certifications: Verify that the vendor adheres to international quality standards (e.g., ISO 9001:2015) and that their products are certified to relevant material specifications (e.g., ASTM, EN, BS, JIS). Request material test reports (MTRs) and mill certificates.

- Technical Expertise and Support: A reputable vendor should possess deep technical knowledge about galvanized pipe manufacturing, applications, and problem-solving. They should be able to provide detailed technical data, advise on product selection, and offer post-sales support.

- Manufacturing Capabilities and Capacity: Assess their production capacity to ensure they can meet your volume requirements and project deadlines, especially for large bulk orders. Inquire about their manufacturing processes and quality control checkpoints.

- Customization and Fabrication Services: For projects with unique requirements, a vendor offering cutting, threading, grooving, or specific coating thicknesses can add significant value.

- Logistics and Delivery Reliability: Evaluate their supply chain management, warehousing capabilities, and ability to deliver on time and to specific project sites, both domestically and internationally.

- Pricing and Payment Terms: While not the sole determinant, competitive pricing coupled with flexible payment terms can significantly benefit project cash flow.

- Reputation and References: Look for vendors with a proven track record, positive customer feedback, and the ability to provide references from similar B2B projects.

Customized Solutions and Project Tailoring

Every industrial project presents unique challenges and specifications. Recognizing this, leading suppliers offer extensive customization capabilities for bulk galvanized pipe to precisely match project demands. Our services extend beyond standard product offerings to encompass comprehensive tailored solutions:

- Specific Dimensions and Lengths: While standard lengths are common, we can provide pipes cut to specific lengths, reducing waste and on-site fabrication costs.

- End Finishing Options: Custom end treatments such as precision threading, grooving, or specialized beveling can be applied to facilitate specific joining methods and accelerate installation.

- Enhanced Coating Thickness: For extremely aggressive environments (e.g., highly corrosive industrial zones or marine applications), we can supply pipes with increased zinc coating thickness, extending service life even further.

- Special Material Grades: Beyond common steel grades, we can source and galvanize pipes made from specific alloy compositions to meet unique mechanical property or chemical resistance requirements.

- Integrated Solutions: This includes providing complementary fittings, valves, and structural components that are also galvanized, ensuring a complete, corrosion-resistant piping system.

Our engineering team collaborates closely with clients from conceptualization to deployment, ensuring that every customized solution is optimized for performance, cost-efficiency, and compliance with all relevant industry standards.

Real-World Application Case Studies

Practical applications demonstrate the tangible benefits of galvanized pipes. These case studies highlight their reliability and performance in demanding environments.

Case Study 1: Municipal Water Distribution Network Upgrade

A major metropolitan area embarked on a multi-phase project to upgrade its aging potable water distribution network, replacing corroded cast iron pipes. The primary challenges included ensuring long-term pipe integrity, minimizing water leakage, and adhering to strict public health standards. Over 500 kilometers of hot-dipped galvanized pipe, ranging from DN150 to DN400, were supplied. The pipes were selected for their exceptional corrosion resistance, non-toxic zinc coating, and robust mechanical properties. After five years in service, the network has reported a 90% reduction in pipe-related leaks and a significant improvement in water quality, demonstrating the long-term reliability and cost-effectiveness compared to alternative materials.

Case Study 2: Industrial Wastewater Treatment Plant

An industrial facility needed a durable piping solution for its new wastewater treatment plant, specifically for the non-potable water lines and structural supports exposed to a humid, chemically active atmosphere. The previous experience with un-galvanized steel resulted in rapid corrosion and frequent replacements. The solution involved the installation of hot-dipped galvanized steel pipes and structural galvanized tubing throughout the plant. The zinc coating provided robust protection against both atmospheric corrosion and incidental chemical exposure. Post-installation, the client noted a drastic reduction in maintenance expenditures related to piping and structural elements, with the galvanized components showing minimal signs of degradation after several years of continuous operation, thereby reducing overall lifecycle costs and ensuring operational continuity.

Ensuring Trust and Authority (Google Standards)

Our commitment to providing high-quality galvanized steel pipe is underpinned by stringent adherence to industry best practices and quality benchmarks. We understand that for B2B clients, trust and authority are paramount.

Certifications and Quality Assurance

All our manufacturing processes and products are rigorously tested and certified to international standards, including ISO 9001 for quality management, ASTM A53 for steel pipe, and ISO 1461/ASTM A123 for hot-dip galvanization. Each batch undergoes comprehensive quality control, including chemical composition analysis, mechanical testing (tensile strength, yield strength, elongation), hydrostatic pressure testing, and non-destructive testing (NDT) such as eddy current testing. Detailed test data and Mill Test Certificates (MTCs) are provided with every order, ensuring full traceability and compliance.

Customer Feedback and Longevity

Our long-standing relationships with industrial clients, municipalities, and construction firms globally underscore our commitment to excellence. Feedback consistently highlights the exceptional durability and minimal maintenance requirements of our galvanized products. We pride ourselves on products that perform reliably for decades, contributing to reduced operational costs and sustained infrastructure integrity for our partners.

Years of Service and Partnerships

With over two decades of dedicated service in the steel materials industry, we have cultivated a deep understanding of market demands and technical challenges. Our extensive network of reputable partner clients and suppliers speaks volumes about our reliability and the quality of our offerings. We are committed to fostering long-term partnerships built on trust, transparency, and consistent product delivery.

Frequently Asked Questions (FAQ) about Galvanized Pipe

- Q: What is the primary difference between hot-dipped and electro-galvanized pipes?

- A: Hot-dipped galvanized pipes have a significantly thicker, more durable zinc coating achieved by immersing the steel in molten zinc, forming a metallurgical bond. Electro-galvanized pipes have a thinner coating applied via electroplating, offering less robust corrosion protection and are generally suitable for less aggressive environments.

- Q: How long does galvanized pipe typically last?

- A: The service life of galvanized pipe varies based on environmental conditions and coating thickness. In typical atmospheric conditions, hot-dipped galvanized pipes can last 50 years or more. In more aggressive industrial or marine environments, a lifespan of 20-30 years is common.

- Q: Can galvanized pipes be welded?

- A: Yes, galvanized pipes can be welded, but it requires specific precautions. The zinc coating vaporizes at welding temperatures, producing zinc oxide fumes which can be hazardous if inhaled. Proper ventilation, respiratory protection, and specialized welding techniques are necessary. Post-welding, the exposed steel at the weld joint will require touch-up with zinc-rich paint to restore corrosion protection.

- Q: Are galvanized pipes safe for drinking water?

- A: Hot-dipped galvanized pipes have historically been used for potable water. However, some regions and building codes now prefer alternative materials like copper or plastic for new installations due to potential for zinc leaching or internal scaling in certain water chemistries over time. Always check local regulations. Our products comply with relevant health standards where applicable.

- Q: What inspection and testing methods are used for galvanized pipes?

- A: Standard inspections include visual checks for coating uniformity, coating thickness measurement (magnetic induction), adhesion tests (hammer test), and mechanical property tests of the base steel. Third-party inspections and specific customer requirements can also be accommodated.

Logistics and Support: Lead Time, Fulfillment, Warranty, and Customer Service

Ensuring a seamless procurement and post-purchase experience is integral to our service philosophy. We are committed to efficient logistics, reliable fulfillment, robust warranty, and responsive customer support for all our galvanized pipe solutions.

Lead Time and Fulfillment

Our state-of-the-art manufacturing facilities and optimized supply chain enable competitive lead times. For standard galvanized pipe orders, typical lead times range from 2-4 weeks. Customized or large-volume orders may require 4-8 weeks, depending on complexity and current production schedules. We provide accurate lead time estimates at the quotation stage and maintain transparent communication throughout the order fulfillment process, including real-time tracking updates.

Warranty Commitments

We stand behind the quality of our galvanized pipes with a comprehensive warranty against manufacturing defects and premature corrosion under specified conditions. Our standard warranty covers materials and workmanship for a period of 12 months from the date of shipment or 18 months from the date of manufacture, whichever comes first. Specific project warranties or extended warranty options can be negotiated based on contract terms and application requirements.

Customer Support Information

Our dedicated customer support team is available to assist with technical inquiries, order status updates, after-sales support, and any concerns that may arise. We offer multiple channels for communication:

- Email Support: Reach our expert team at info@world-steelmaterial.com for detailed queries.

- Phone Support: Contact our sales and support representatives during business hours at [Insert Phone Number Here, e.g., +86-123-4567-8900].

- Online Portal: Access project documentation, order history, and submit support tickets through our client portal at world-steelmaterial.com/client-portal (example).

We are committed to providing prompt, professional, and effective support to ensure your projects proceed without interruption.

Conclusion

In summary, the strategic selection and deployment of high-quality hot-dipped galvanized steel pipes are pivotal for achieving durable, cost-effective, and sustainable infrastructure across diverse industrial and municipal applications. From the meticulous manufacturing process that imbues each pipe with its characteristic corrosion resistance to the extensive range of technical specifications and customization options available, galvanized pipes represent a sound investment for any project demanding longevity and reliability.

By understanding the critical advantages, embracing the various types, and engaging with experienced vendors who prioritize quality and client-specific solutions, B2B decision-makers can ensure the long-term success and integrity of their ventures. Our commitment to meeting rigorous quality standards, coupled with comprehensive support and technical expertise, positions us as a trusted partner in supplying superior galvanized piping solutions globally.

References

- American Society for Testing and Materials. ASTM A123/A123M-17: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products. ASTM International, 2017.

- International Organization for Standardization. ISO 1461: Hot-dip galvanized coatings on fabricated iron and steel articles – Specifications and test methods. ISO, 2022.

- Galvanizers Association. (n.d.). Life Expectancy of Hot Dip Galvanized Steel. Retrieved from [industry association website providing technical guidance on galvanization, e.g., galvanizeit.org/hot-dip-galvanizing/how-long-does-it-last].

- British Standards Institution. BS 1387: Specification for screwed steel tubes and tubulars and for plain end steel tubes suitable for welding or for screwing to BS 21 pipe threads. BSI, 1985.

Post time: Aug . 30, 2025 06:40