The Imperative Role of Anti-Corrosion Pipes in Modern Infrastructure

In demanding industrial environments, the integrity and longevity of pipeline systems are paramount. Corrosion poses a relentless threat, leading to significant material degradation, operational inefficiencies, environmental hazards, and substantial financial losses. Addressing this challenge effectively requires advanced solutions, with the anti corrosion pipe emerging as a critical component in safeguarding vital infrastructure. These specialized pipes, often enhanced with advanced coatings like 3LPE, PP, or FBE, are engineered to withstand aggressive corrosive agents, ensuring the safe and efficient transport of various media over extended periods.

Our focus herein delves into the technical intricacies, application diversity, and strategic advantages of modern anti-corrosion solutions, providing B2B decision-makers and engineers with comprehensive insights into selecting optimal pipeline protection. We will explore the manufacturing excellence, performance metrics, and the commitment to quality that underpins reliable anti-corrosion pipe systems.

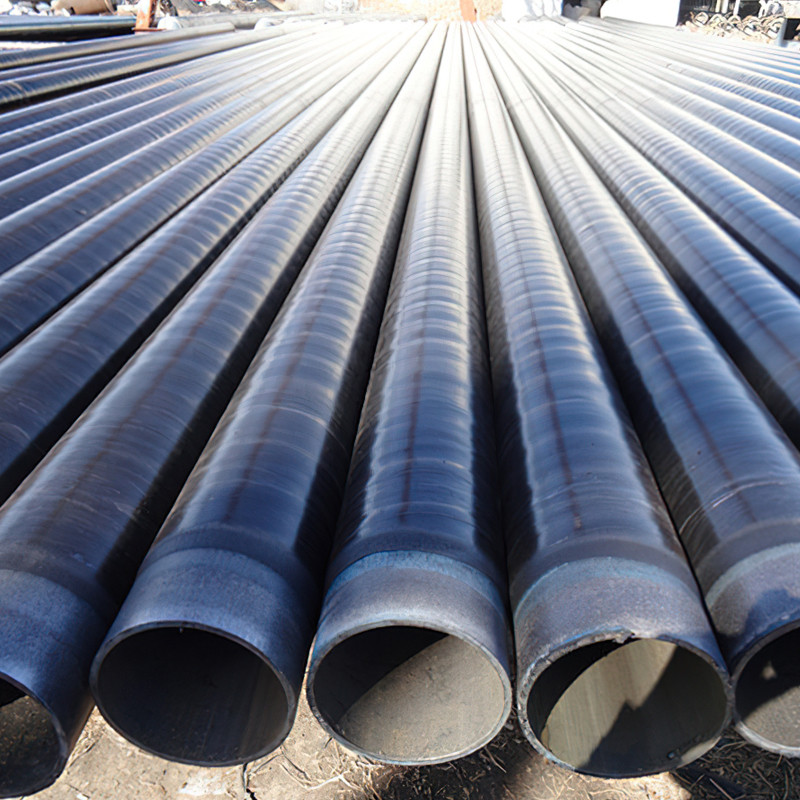

Figure 1: Advanced anti corrosion pipe solutions deployed in critical infrastructure.

Industry Trends and Market Dynamics

The global demand for robust and sustainable infrastructure continues to surge, driven by rapid urbanization, industrial expansion, and the increasing need for reliable energy and water supply. This growth intrinsically elevates the importance of effective corrosion prevention, positioning the anti corrosion pipe market for significant expansion. Key trends include:

- Regulatory Stringency: Stricter environmental regulations and safety standards (e.g., API, ISO) are mandating enhanced pipeline integrity, pushing industries towards superior corrosion protection methods.

- Technological Advancements: Continuous innovation in polymer science and coating application techniques leads to more durable, environmentally friendly, and cost-effective anti corrosion pipe coating solutions.

- Aging Infrastructure Renewal: A significant portion of existing global pipeline infrastructure is nearing the end of its design life, necessitating replacement with technologically advanced and corrosion-resistant materials.

- Demand for Extended Service Life: Industries are prioritizing solutions that offer longer operational lifespans (50+ years), reducing maintenance costs and operational disruptions.

The market's trajectory is also influenced by geopolitical factors, fluctuating raw material costs, and the ongoing transition towards cleaner energy sources, all of which underscore the long-term value of investing in high-quality anti corrosion pipe systems.

Technical Specifications and Advanced Coating Systems

The effectiveness of an anti corrosion pipe is primarily defined by its base material and, critically, its protective coating. Typically, the base material is high-grade carbon steel or stainless steel, forming an anti corrosion steel pipe backbone. The choice of coating system—3LPE, PP, or FBE—depends on specific project requirements, operational temperature, environmental conditions, and desired service life.

Understanding Coating Technologies: 3LPE, PP, and FBE

- 3LPE (Three-Layer Polyethylene) Coating: This system consists of three layers: a high-performance fusion bonded epoxy (FBE) primer for excellent adhesion and corrosion protection, a copolymer adhesive layer, and an outer layer of polyethylene (PE) for physical protection. It's widely used for operating temperatures up to 80°C.

- 3LPP (Three-Layer Polypropylene) Coating: Similar in structure to 3LPE, but with an outer layer of polypropylene (PP). This offers superior high-temperature performance, suitable for applications up to 110-120°C, and provides enhanced abrasion resistance.

- FBE (Fusion Bonded Epoxy) Coating: A single-layer thermoset coating applied as a dry powder that fuses to the preheated pipe surface. FBE offers excellent adhesion, cathodic disbondment resistance, and is ideal for operating temperatures up to 85°C. It's also suitable as an internal coating.

Key Product Specifications

The following table outlines typical specifications for an anti corrosion pipe with various coating options, adhering to international standards like ISO 21809, DIN 30670, and CSA Z245.21.

| Parameter | 3LPE Coating | 3LPP Coating | FBE Coating |

|---|---|---|---|

| Applicable Standards | ISO 21809-1, DIN 30670, CSA Z245.21 | ISO 21809-1, DIN 30678 | AWWA C213, ISO 21809-2, API RP 5L7 |

| Max. Operating Temperature | Up to 80°C | Up to 110-120°C | Up to 85°C |

| Coating Thickness (min) | 2.5 mm (for DN100-250), 3.0 mm (for DN250-500) | 2.7 mm (for DN100-250), 3.2 mm (for DN250-500) | 350-450 microns (0.35-0.45 mm) |

| Adhesion (min) | ≥30 N/cm (at 23°C) | ≥35 N/cm (at 23°C) | ≥12 MPa (at 23°C) |

| Impact Resistance (J/mm) | ≥10 | ≥12 | No cracking or disbondment |

| Cathodic Disbondment (mm) | ≤7 mm (28 days, 23°C) | ≤6 mm (28 days, 23°C) | ≤8 mm (28 days, 65°C) |

Figure 2: Illustrative cross-section of a multi-layer anti-corrosion pipe coating.

Detailed Manufacturing Process Flow for Anti-Corrosion Pipes

The production of a high-performance anti corrosion pipe involves a meticulously controlled, multi-stage process designed to ensure optimal adhesion, uniformity, and durability of the protective coating. From raw material inspection to final quality assurance, each step is critical:

Process Steps:

- Pipe Preparation: The process begins with raw steel pipes (e.g., seamless, ERW, LSAW) meeting specifications such as API 5L, ASTM, or EN standards. Pipes undergo thorough visual inspection and dimensional checks.

- Surface Cleaning and Blasting: Pipes are transported to a cleaning station where oil, grease, and other contaminants are removed. Subsequently, they enter an abrasive blast cleaning chamber (often using steel grit or shot) to achieve a near-white metal finish (Sa 2.5 or Sa 3 according to ISO 8501-1). This roughens the surface, enhancing the mechanical adhesion of the coating.

- Induction Heating: After blasting, pipes are rapidly heated to the specified application temperature (typically 180-230°C for FBE and 3LPE/PP) using induction coils. This ensures proper curing and adhesion of the coating materials.

- FBE Application (for 3LPE/PP and FBE): For 3LPE/PP systems, a thin layer of fusion bonded epoxy (FBE) powder is electrostatically sprayed onto the hot pipe surface. The FBE powder melts, flows, and cures to form a continuous film, providing primary corrosion protection. For FBE-only coatings, this is the final coating layer.

- Adhesive Layer Application (for 3LPE/PP): Immediately after FBE, a copolymer adhesive layer is applied. This intermediate layer chemically bonds the FBE to the outer polyethylene/polypropylene layer, preventing delamination.

- Polyethylene/Polypropylene Extrusion (for 3LPE/PP): The final protective layer of polyethylene (PE) or polypropylene (PP) is applied over the adhesive layer, typically by side extrusion. This robust outer layer provides excellent mechanical protection against abrasion, impact, and UV radiation.

- Quenching and Cooling: The coated pipe is then cooled in a water spray to solidify the coating and prevent damage.

- End Cutting and Beveling: The pipe ends are trimmed and beveled as per project specifications, ensuring readiness for welding.

- Quality Control and Testing: A series of rigorous tests are performed to ensure the integrity and performance of the anti corrosion pipe coating:

- Holiday Detection: High voltage electrical inspection to detect any pinholes or discontinuities in the coating.

- Coating Thickness Measurement: Verification of specified coating thickness using magnetic induction gauges.

- Adhesion Test: Cross-hatch or peel tests to ensure strong bond strength between layers and to the pipe surface.

- Impact Resistance Test: Assessment of the coating’s ability to withstand mechanical impact.

- Cathodic Disbondment Test: Evaluates the coating's resistance to disbondment under cathodic protection conditions.

- Bend Test: For certain standards, evaluating coating flexibility.

- Marking and Storage: Approved pipes are marked with essential information (manufacturer, coating type, date) and stored appropriately to prevent damage before shipment.

Figure 3: Schematic representation of the anti-corrosion pipe coating process.

Key Technical Advantages and Performance Benefits

Investing in high-quality anti corrosion pipe systems offers a multitude of technical and economic advantages crucial for long-term project success:

- Extended Service Life: With proper application and maintenance, coated pipes can achieve a service life exceeding 50 years, significantly outperforming unprotected or minimally coated pipes. This reduces the need for frequent replacements and associated costs.

- Superior Corrosion Resistance: The multi-layered structure of 3LPE/PP coatings and the robust nature of FBE provide an impermeable barrier against corrosive elements, including soil chemicals, moisture, acids, and alkalis. This is especially vital for buried or submerged pipelines.

- Excellent Mechanical Protection: The polyethylene or polypropylene outer layers offer outstanding resistance to abrasion, impact, and mechanical damage during handling, installation, and backfilling, minimizing the risk of coating damage that could lead to localized corrosion.

- Reduced Maintenance Costs: By preventing corrosion, these pipes drastically lower the frequency and intensity of inspection, repair, and replacement activities, leading to substantial operational savings over the pipeline’s lifespan.

- Enhanced Flow Efficiency (Internal Coatings): For applications requiring internal corrosion protection, FBE coatings provide a smooth surface, reducing friction and energy consumption during fluid transport. This translates to energy savings and reduced pumping costs.

- Environmental Protection: Preventing pipeline leaks caused by corrosion safeguards the environment from potential contamination by transported fluids (e.g., oil, gas, chemicals), aligning with corporate social responsibility and regulatory compliance.

- Temperature Versatility: While 3LPE handles standard temperatures, 3LPP coatings extend suitability to high-temperature environments, providing flexibility across diverse project requirements. This makes a well-specified anti corrosion pipe highly adaptable.

These combined advantages underscore why specialized anti corrosion pipe coating systems are not just an expense, but a strategic investment for critical infrastructure projects.

Application Scenarios and Target Industries

The versatility and robust performance of the anti corrosion pipe make it indispensable across a broad spectrum of industries, where pipeline integrity is non-negotiable. Its primary target industries include:

- Oil and Gas (Onshore & Offshore): Essential for crude oil, natural gas, and refined product transmission pipelines. Coatings protect against harsh underground environments, seawater corrosion, and high operating temperatures. The reliability of an anti corrosion steel pipe is critical in this sector.

- Water Supply and Drainage: Used for potable water transmission, wastewater, and sewage systems. Anti-corrosion coatings ensure water quality and prevent leaks that could lead to service disruptions or environmental issues.

- Chemical and Petrochemical Plants: Transporting various corrosive chemicals and industrial effluents requires pipes with superior chemical resistance, often leveraging the specific properties of FBE or PP coatings.

- Mining Industry: Handling abrasive slurries and corrosive process water. The mechanical toughness of 3LPE/PP is particularly beneficial in these demanding conditions.

- Power Generation: Used in cooling water systems, fuel lines, and waste disposal systems, where high temperatures and corrosive media are common.

- Offshore and Marine Applications: Subsea pipelines, risers, and structural components exposed to seawater and marine environments rely heavily on specialized heavy-duty anti-corrosion coatings.

In scenarios like long-distance oil and gas transmission in deserts or sub-zero conditions, or municipal water distribution networks exposed to varied soil chemistries, the chosen anti corrosion pipe solution directly impacts system reliability, safety, and economic viability. Even niche applications like specialized coatings or anti corrosion paint for copper pipe used in HVAC or plumbing require tailored approaches based on material interaction and environmental factors.

Figure 4: Anti-corrosion pipes in a complex industrial setting.

Vendor Comparison and Customized Solutions

Selecting the right anti corrosion pipe supplier is as critical as the pipe itself. A reliable vendor offers not just products, but also expertise, technical support, and the capability for customized solutions. When evaluating 3lpe coating suppliers or providers of other advanced coatings, consider the following:

Key Vendor Selection Criteria:

- Certifications and Compliance: Verify adherence to international standards (ISO 9001, API, NACE) and local regulatory requirements. These ensure consistent quality and performance.

- Experience and Track Record: A proven history of successful projects in relevant industries demonstrates expertise and reliability. Look for long-standing client relationships.

- Production Capacity and Lead Time: Assess the supplier’s ability to meet project deadlines and handle large-scale orders without compromising quality.

- Technical Support and R&D: A vendor who invests in research and development and offers robust technical support can provide innovative solutions and assist with complex challenges.

- Customization Capabilities: The ability to tailor coating thickness, pipe diameter, lengths, and specific coating types to unique project specifications is invaluable.

- Quality Control Procedures: Inquire about their internal QC/QA protocols, including destructive and non-destructive testing regimes.

Product Comparison: 3LPE vs. FBE vs. 3LPP

While we've detailed their individual specs, a direct comparison helps in strategic selection:

| Feature | 3LPE Coating | FBE Coating | 3LPP Coating |

|---|---|---|---|

| Primary Use | External corrosion for buried/submerged pipes | Internal & External for moderate temps, excellent adhesion | External corrosion for high-temp, abrasion-prone environments |

| Temperature Range | -40°C to +80°C | -30°C to +85°C | -20°C to +110°C (or higher) |

| Mechanical Protection | Excellent (due to thick PE layer) | Good (less compared to 3LPE/PP) | Superior (due to thick PP layer, higher impact resistance) |

| Cathodic Disbondment | Very Good | Excellent | Very Good |

| Flexibility | Good | Excellent | Moderate (less flexible than 3LPE/FBE) |

| Cost Effectiveness | Moderate to High | Moderate | High (due to high-temp performance) |

Figure 5: Customized anti-corrosion pipe solutions awaiting shipment.

Application Case Studies and Success Stories

Real-world applications powerfully demonstrate the efficacy and reliability of anti corrosion pipe systems:

- Major Oil & Gas Transmission Pipeline (Middle East): A multi-billion dollar project involving thousands of kilometers of pipelines across desert terrains and coastal regions utilized large-diameter (up to 48-inch) 3LPE coated anti corrosion steel pipe. The chosen coating system provided robust protection against highly corrosive desert soils, extreme temperatures, and mechanical damage during installation, contributing to a projected service life of over 60 years and significantly reducing operational risks and maintenance requirements.

- High-Pressure Water Main Rehabilitation (North America): An urban water utility faced severe external corrosion issues on aging cast iron pipes, leading to frequent bursts and water loss. They opted for replacement with FBE-coated ductile iron and steel pipes for key sections. The FBE coating provided excellent long-term protection against aggressive urban soil conditions, reducing future repair costs and ensuring reliable potable water delivery to millions of residents.

- Offshore Gas Gathering Network (Southeast Asia): In a challenging subsea environment with high operating temperatures and strong currents, 3LPP-coated pipelines were deployed for a gas gathering network. The 3LPP system offered superior temperature resistance (withstanding fluid temperatures up to 100°C) and exceptional mechanical protection against seabed abrasion and impact during laying operations, proving its resilience in deepwater applications.

- Industrial Wastewater Treatment Plant (Europe): For transporting highly corrosive industrial effluents, a combination of FBE internal and 3LPE external coatings was specified for a network of carbon steel pipes. This dual-layer approach addressed both the aggressive chemical nature of the wastewater and the corrosive underground environment, ensuring the plant's operational continuity and environmental compliance.

These cases exemplify how tailored anti corrosion pipe coating solutions are pivotal in delivering long-term value, enhancing safety, and ensuring environmental stewardship across diverse and demanding industrial landscapes.

Commitment to Quality, Support, and Trust

Our commitment extends beyond manufacturing high-quality anti corrosion pipe solutions. We understand that trust and reliability are built on a foundation of rigorous quality assurance, transparent processes, and unwavering customer support. Our adherence to international standards and robust service framework ensures client confidence.

Authoritative Standards and Certifications:

We operate under stringent quality management systems, certified to ISO 9001, demonstrating our consistent ability to meet customer and regulatory requirements. Our products comply with major industry specifications, including API 5L, ISO 21809 series, DIN, and AWWA standards, which are internationally recognized benchmarks for pipeline integrity and performance.

FAQ Module: Common Questions Answered

- Q: What is the typical lead time for a custom anti corrosion pipe order?

- A: Lead times vary based on pipe dimensions, coating type, order volume, and current production schedules. Standard orders typically range from 4 to 8 weeks, with expedited options available for urgent projects. We provide precise estimates upon order confirmation.

- Q: What warranty is offered on your anti-corrosion pipe products?

- A: Our anti corrosion pipe products typically come with a standard warranty covering material and manufacturing defects for a specified period (e.g., 10-15 years), contingent on proper handling, installation, and usage as per industry best practices. Extended warranty options may be available for specific projects.

- Q: How do you ensure the quality of coating adhesion?

- A: Coating adhesion is critical. We employ advanced surface preparation (Sa 2.5/3 blasting) and conduct rigorous adhesion tests (peel test, cross-hatch) in our in-house laboratories, complying with standards like ISO 21809 and ASTM D3359. Every batch undergoes comprehensive quality checks.

- Q: Can you provide third-party inspection and test reports?

- A: Absolutely. We regularly collaborate with reputable third-party inspection agencies (e.g., SGS, Bureau Veritas, TUV) to provide independent verification of our products and processes. All relevant test reports and certification documents are provided with each shipment.

Customer Support and After-Sales Service:

Our dedicated technical support team is available to assist clients from project inception through execution and beyond. This includes expert consultation on material selection, coating specifications, installation guidance, and troubleshooting. We prioritize long-term partnerships, ensuring that our clients receive comprehensive support for the entire lifespan of their pipeline assets.

Figure 6: Rigorous quality control measures ensuring pipe integrity.

Conclusion

The deployment of high-performance anti corrosion pipe solutions is more than a precautionary measure; it is a fundamental pillar of modern industrial infrastructure. By mitigating the pervasive threat of corrosion, these specialized pipes ensure operational continuity, enhance safety, reduce environmental impact, and deliver significant economic advantages over the long term. Through adherence to stringent technical specifications, continuous innovation in coating technologies (3LPE, PP, FBE), and a steadfast commitment to quality and customer support, manufacturers are empowering industries to build robust, reliable, and sustainable pipeline networks for decades to come.

References

- ISO 21809-1:2018. Petroleum and natural gas industries — External coatings for buried or submerged pipelines used in pipeline transportation systems — Part 1: Polyolefin coatings (3-layer PE and 3-layer PP). International Organization for Standardization.

- NACE International Standard SP0169-2013. Control of External Corrosion on Underground or Submerged Metallic Piping Systems. NACE International.

- API Recommended Practice 5L7. Recommended Practice for Unprimed External Fusion Bonded Epoxy Coating of Line Pipe. American Petroleum Institute.

- AWWA C213-14. Standard for Fusion-Bonded Epoxy Coating for the Interior and Exterior of Steel Water Pipelines and Fittings. American Water Works Association.

- ASTM D3359-09. Standard Test Methods for Measuring Adhesion by Tape Test. ASTM International.

- DIN 30670:2012-07. Polyethylene coatings for steel pipes and fittings - Requirements and testing. Deutsches Institut für Normung e.V.

Post time: Sep . 12, 2025 11:00