Hydraulic Pipe Fittings Machine is a key solution in the manufacturing industry, specifically within Special Equipment Manufacturing Industry and Manufacturing of metal processing machinery. This article explores how Beijing Sinoworld Steel Material Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Hydraulic Pipe Fittings Machine Overview

- Benefits & Use Cases of Hydraulic Pipe Fittings Machine in Manufacturing of metal processing machinery

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Hydraulic Pipe Fittings Machine from Beijing Sinoworld Steel Material Co., Ltd.

Hydraulic Pipe Fittings Machine Overview

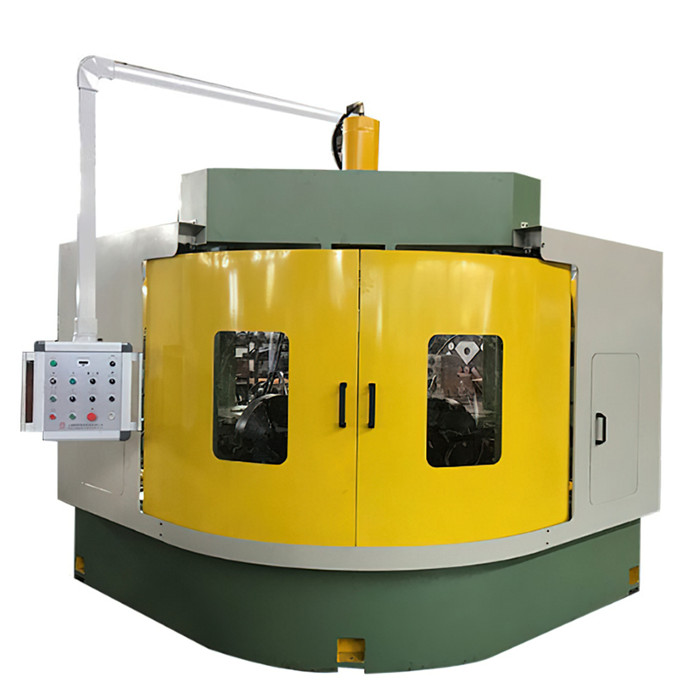

A Hydraulic Pipe Fittings Machine is engineered to form, end-finish, and prepare pipe and tube components—such as elbows, tees, reducers, and couplings—with repeatable accuracy and high throughput. In the Special Equipment Manufacturing Industry, it occupies a strategic position on the production line, enabling cold-forming, expanding, swaging, flaring, and beveling operations under precise hydraulic control. For manufacturers of metal processing machinery, the machine’s stability, tonnage capacity, stroke precision, and tooling flexibility directly influence cycle times, scrap rates, and overall equipment effectiveness (OEE).

Typical configurations include servo-hydraulic power packs, PLC/HMI control, closed-loop position and pressure feedback, and interchangeable tooling for multi-size production. When integrated with dedicated fixtures, the same platform can support tee forming machine operations for T-branch fittings, as well as integrated chamfering and beveling before welding or coating. Beijing Sinoworld Steel Material Co., Ltd. designs and supplies robust systems built to international standards, pairing heavy-duty frames with precise motion control. Their portfolio, which includes specialized beveling solutions like the Q1245 series, helps customers streamline pre-weld preparation and achieve consistent weld-ready edges across a wide range of diameters and materials.

Benefits & Use Cases of Hydraulic Pipe Fittings Machine in Manufacturing of metal processing machinery

In metal processing machinery environments, Hydraulic Pipe Fittings Machines are deployed for oil & gas pipeline components, HVAC and fire-protection systems, water and wastewater networks, and structural pipe assemblies. They support critical tasks including hot/cold forming of elbows, hydraulic bulging for tees, end swaging for coupling fitment, and beveling to prepare weld edges that meet downstream quality specifications. With modular tooling, one line can switch between multiple diameters and wall thicknesses, reducing changeover time and supporting mixed-batch production without sacrificing accuracy.

Competitive advantages include high forming forces with smooth pressure ramps (protecting metallurgical integrity), programmable recipes for rapid repeat setups, and integrated safety and diagnostics. When paired with upstream cutting and downstream inspection, the machine becomes the backbone of a lean, traceable production cell. Beijing Sinoworld Steel Material Co., Ltd. brings deep application knowledge—covering materials from carbon steel and stainless steel to alloy grades—and supports customers with process tuning, tooling selection, and commissioning. Their engineering team helps align tonnage, stroke, die design, and bevel geometries with your specification to shorten process steps while maintaining stringent dimensional tolerances and weld quality.

Cost, Maintenance & User Experience

Total cost of ownership (TCO) for a Hydraulic Pipe Fittings Machine hinges on throughput, scrap reduction, tooling longevity, energy consumption, and maintenance. Durable frames and precision hydraulics extend service life, while servo-controlled motion can lower energy usage per part. Predictable, recipe-driven forming and beveling reduce rework and inspection bottlenecks—boosting ROI by consolidating operations and stabilizing quality. For B2B decision makers, this translates into fewer unplanned stoppages, faster PPAP or first-article approvals, and a clearer path to OEE targets.

Maintenance is simplified through accessible manifolds, filtration monitoring, and standardized seals. Recommended practices include hydraulic fluid analysis at defined intervals, routine calibration of pressure/position sensors, and proactive inspection of wear surfaces and tooling. Beijing Sinoworld Steel Material Co., Ltd. supports lifecycle performance with operator training, spare parts programs, and remote diagnostics to minimize MTTR. Customer feedback in the Special Equipment Manufacturing Industry consistently highlights stable cycle times, user-friendly HMIs, and repeatable bevel geometries that reduce welding defects—key contributors to predictable capacity planning and lower cost-per-part.

Sustainability & Market Trends in manufacturing

Manufacturers face growing pressure to decarbonize operations, document energy intensity, and comply with stricter safety and environmental standards. Modern Hydraulic Pipe Fittings Machines contribute to these goals through efficient power units, smart standby modes, and cleaner hydraulic fluid options. In parallel, Industry 4.0 connectivity enables condition monitoring, energy tracking, and traceability from cut length to final bevel—data that helps satisfy audits and continuous-improvement programs. As infrastructure renewal, LNG and hydrogen projects, and urban utilities expand globally, demand for high-integrity fittings and weld-ready pipe ends continues to rise.

Beijing Sinoworld Steel Material Co., Ltd. is aligning with these trends by emphasizing energy-efficient components, robust guarding and safety interlocks, and digital-ready controls for plant-wide integration. Whether the application is tee forming machine operations for branch lines or precision beveling ahead of automated welding cells, their solutions support lower scrap, safer operation, and consistent quality—all while helping customers report on sustainability metrics. The result is equipment that not only meets today’s production targets but is ready for tomorrow’s compliance and data-driven manufacturing requirements.

Conclusion on Hydraulic Pipe Fittings Machine from Beijing Sinoworld Steel Material Co., Ltd.

For manufacturers in the Special Equipment Manufacturing Industry and the broader metal processing machinery sector, a Hydraulic Pipe Fittings Machine is central to forming, end-finishing, and preparing weld-ready components with speed and precision. By combining hydraulic power, intelligent control, and flexible tooling, it elevates quality while controlling cost-per-part. Beijing Sinoworld Steel Material Co., Ltd. stands out for durable designs, attentive engineering support, and solutions that integrate seamlessly from cutting to beveling and beyond.

- Contact us: email: garvinliu@world-steelmaterial.com

- Visit our website: https://www.world-steelmaterial.com

- Explore product details: Q1245 Beveling Machine

Post time: Nov . 14, 2025 08:40