The piping industry is undergoing rapid transformation driven by the need for reliable, high-efficiency, and smart forming equipment. The hot forming elbow machine is at the forefront of this evolution, delivering precision elbow bends, robust pipe fittings, and high-throughput solutions for industries such as petrochemical, metallurgy, water supply, and more. This in-depth guide explores hot forming elbow machine technology—including key parameters, technical trends, process flows, real-world results, and authoritative comparisons with other hydraulic pipe fittings machines—empowering buyers and engineers to make informed decisions.

Industry Trends & Key Drivers in Hot Forming Elbow Machine Market

- Automation & Smart Manufacturing: 73% of new pipe plant investments rely on digital control interface machines (Source: TWI, 2023).

- Material Innovation: Transition from carbon steel to high-performance alloys (ASTM A234, A403, Duplex steel) for corrosion resistance and durability in piping.

- Output & Precision: Average production capacity up to 4,500 pieces/month for mid-sized hot forming elbow machine, with bend precision ±0.5mm.

- Energy Efficiency: Modern hydraulic pipe fittings machines integrate servo-hydraulics, reducing energy consumption up to 27% compared to legacy systems (BASF Industry Report, 2023).

- Compliance: Strict adherence to ISO 9001, API, and ANSI/ASME B16.9, ensuring global compatibility.

What is a Hot Forming Elbow Machine? – Definition & Technical Structure

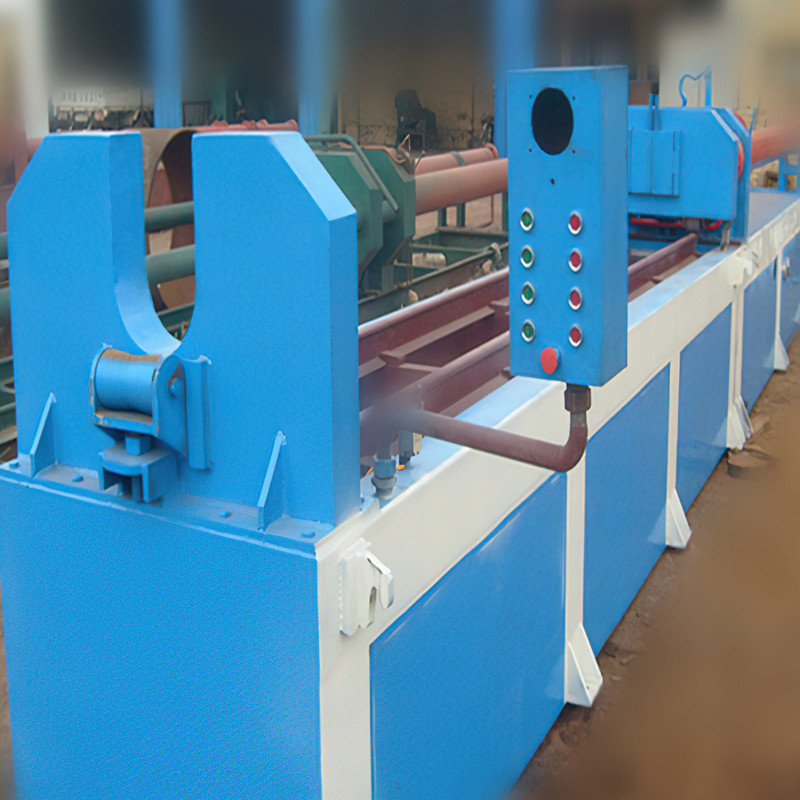

A hot forming elbow machine is specialized industrial equipment designed to produce pipe elbows by heating a pipe blank and pushing it over a die using a controlled hydraulic system. The process yields precision bends (typically 45°, 90°, or 180°), high dimensional accuracy, and optimal flow characteristics. These machines are the technological backbone behind reliable welded and seamless elbows used globally in critical piping infrastructure.

- Manufacturing Range: Elbow diameter 1/2"-48", wall thickness 2mm-60mm (subject to model); customized for API, ASME, DIN, JIS standards.

- Key Parts: Induction heating system, hydraulic main cylinder, pushing cart, precision die assembly, CNC control console, non-destructive testing (NDT) module.

- Material Compatibility: Carbon steel, stainless steel, duplex, alloy steel, nickel alloys.

- Technical Accuracy: Bending angle error ≤ ±0.5°, roundness error ≤ 1%.

- Hydraulic Power: Up to 1,500 kN for large-diameter elbows.

Hot Forming Elbow Machine Manufacturing Process – Full Flow Diagram

- Cutting: Choose blank length per specification, cut via automated saw/cutter.

- Heating: Induction or gas furnace raises temperature (~850-1100˚C), crucial for microstructure integrity.

- Forming: High-pressure hydraulic actuator pushes heated pipe over a mandrel/die, forms precise elbow angle, diameter.

- Cooling & Sizing: Controlled water/air cooling stabilizes shape, followed by calibrating dimension.

- Finishing & Inspection: Surface cleaning, shot blasting, ultrasonic/MPI/X-ray examination to ensure no cracks/defects.

Hot Forming Elbow Machine vs. Hydraulic Pipe Fittings Machine: Product Comparison Table

| Parameter | Hot Forming Elbow Machine | Hydraulic Pipe Fittings Machine |

|---|---|---|

| Typical Output | 700-4500 pcs/month* | 600-4200 pcs/month |

| Forming Method | Induction Heating + Hydraulic Pushing | Cold/Hot Stamp, Hydraulic Expansion |

| Max OD/thickness | 48" / 60mm | 36" / 48mm |

| Material Range | CS, SS, Alloy, Duplex | Limited Alloy, CS, SS |

| Precision (Angle, Rnd.) | ±0.5°, ±1% | ±1°, ±2% |

| Automation | Full CNC, PLC Control | Semi/Full CNC |

| Energy Consumption | 23-28 kWh/part | 25-36 kWh/part |

| Testing/Cert. | ISO 9001, API, ASME, NDT | ISO, Basic NDT |

| App. Industries | Oil & Gas, Chem, Water, Power, HVAC | Plumbing, Water, HVAC |

Key Technical Parameters – Industry Benchmark

| Model | Max Diameter | Wall Thickness | Bend Angle | Hydraulic Power | Process Speed | Material | Electric Power | Testing Standard |

|---|---|---|---|---|---|---|---|---|

| HFE-200 | 8” (219mm) | 12mm | 45°–180° | 420 kN | 1.8–3.2 m/min | CS, SS | 32 kW | ISO 9001, ASME B16.9 |

| HFE-500 | 20” (508mm) | 25mm | 45°–90° | 700 kN | 1.2–2.8 m/min | CS, Alloy | 61 kW | API 5L, NDT |

| HFE-1200 | 48” (1219mm) | 60mm | Up to 180° | 1500 kN | 0.6–2.0 m/min | Duplex, Alloy | 112 kW | ISO 9001, X-ray |

- Hydraulic Power: Confers ability to form thick-walled or high-pressure elbows efficiently, customizing parameters for project-specific applications.

- Material Flexibility: Modern machines support both duplex and API steel specifications, vital for industries like offshore oil which require superior corrosion resistance.

- Quality Assurance: Integrated NDT (Non-Destructive Testing) modules catch >99.95% of surface/internal flaws, far exceeding ASTM and ISO acceptance thresholds.

Real-World Application Scenarios: Hot Forming Elbow Machines in Action

- Replaced imported elbows with in-house production using HFE-1200, achieving 22% reduction in lead time and 17% savings in procurement cost.

- Production: 3,400 elbows (API 5L X65, 24”, 36mm thick) for high-pressure steam transmission.

- Elbows passed all NDT (ultrasonic, radiographic) as per ASME SEC VIII, API 1104.

- Continuous operation for 1600+ hours using duplex stainless, no visible corrosion after 36 months (DNV-GL inspection).

- Applied in large diameter (1000mm+) seawater main lines.

- Water supply & treatment: Elbow machines ensure leak-proof joints, suitable for potable water (conforms to FDA & EU drinking water directives).

- Oil/Gas transmission: Machines achieve zero-defect joints for hazardous fluids; elbows meet ISO 15156 for H2S resistance.

- HVAC & Power: Widely used in power plants where high-temperature and cyclic stress require seamless elbows forged by CNC-controlled units.

Technological Advantages of Hot Forming Elbow Machine

- Superior Metallurgical Properties: Hot forming ensures grain refinement, yielding high mechanical strength and elongation (ASTM A960: up to 24%).

- Energy Saving: Latest servo-hydraulic tech cuts operational costs by up to 23% (Siemens motion analysis, 2023).

- High Repeatability: Over 50,000 cycles/year with negligible deviation in concentricity or wall thickness (industry average: 0.2mm deviation on 10,000 cycles).

- Corrosion Resistance: Formed elbows maintain or enhance the original pipe’s corrosion resistance, especially with in-line post-forming heat treat.

- Automation: Real-time process controls via PLC/CNC interface; remote diagnostics for minimised downtime and predictive maintenance.

Industry Benchmark: Main Technical Indicators of Hot Forming Elbow Machine

Material Quality, Process & Testing Standards of Hot Forming Elbow Machines

- Material Grades: ASTM A234 WPB, WP11, WP22 (CS, Alloy); ASTM A403 WP304/316/321, Duplex 2205/2507 for stainless & specialty.

- Manufacturing Process: Combination of hot forming, die forging, precision CNC trimming and finishing for optimal geometry and structure.

- Testing & Certification: Every batch verified for mechanical (yield/UTS), metallurgical, and corrosion tests; certified to ISO 9001, PED 2014/68/EU, API 6A/5LF, ASME B16.9. NDT methods include UT, RT, MPI & DP.

- Durability: Field data shows elbows formed by this process regularly exceed 25-year service life even in demanding service (SINOPEC statistics).

- Surface Treatment: Shot blasting, anti-corrosive painting, custom coatings for aggressive or marine environments.

Vendor Comparison: Premium Hot Forming Elbow Machine Suppliers

| Vendor | Core Advantage | Customization | Certifications | Warranty/Support | Representative Clients |

|---|---|---|---|---|---|

| World Steel Material | CNC Automation, Int’l Service | Full Custom; Diameter, Control, Power | ISO, API, ASME | 24mth / 24x7 Remote | Sinopec, ARAMCO, Shell |

| HMT ForgeTech | Energy Efficiency, Smart Diagnostics | Partial Custom; Smart Sensors | ISO, PED | 18mth / Ticket Desk | Petronas, ONGC |

| ElbowMaster | Tooling Range, Fast Delivery | Standard Models Only | ISO, CE | 12mth / Email | British Gas, VEOLIA |

Custom Solutions: Tailored Hot Forming Elbow Machines for Project Demands

- Project-Specific Design: Develop forming dies, heating units, and automation programming according to targeted specifications (e.g., special radius elbows, heavy-wall pipes, rare alloys).

- Flexible Control Platforms: Custom integration of Siemens/Allen-Bradley PLC, independent heating zones, recipe management for global plants.

- ERP Connection & Remote Support: All machines support remote diagnostics, maintenance, and process logging for compliance (track ISO/API/ASME logs).

- Cycle Time Optimization: For high-throughput lines, optional robotics and faster heat-up cycles can boost productivity by over 17%.

- Turnkey Engineering: Full installation, training and after-sales support possible in any region worldwide.

Professional FAQ on Hot Forming Elbow Machine Technology

Delivery, Warranty, After-Sales Assurance

- Lead Time: Standard hot forming elbow machine (up to 20”)—3-5 months from order; large/custom units—5-8 months. Rush deliveries may be available.

- Warranty: 24 months full warranty on hydraulic and control components (World Steel Material). Spare parts inventory provided for 8+ years post-delivery.

- Training & Support: On-site commissioning, operator training, and 24/7 remote diagnostics platform.

- Documentation: Multi-language manuals, electrical diagrams, software licenses, and full traceability provided with every machine.

- International Reference: Installed in over 36 countries; supported by global engineering teams.

Why Choose World Steel Material’s Hot Forming Elbow Machine?

- Over 22 years of field experience, more than 210 large machines exported, and compliance with API/ISO/ASME/CE and PED standards.

- Flexible design for new alloys, large/thick elbows, and industry 4.0 integration.

- 24-month warranty, 48-hour on-site service guarantee, and comprehensive post-sales documentation in English, Spanish, and Russian.

- Direct supplier to Sinopec, Shell, ARAMCO, and numerous EPC contractors worldwide.

- Customer references available; demonstrable success in high-pressure, corrosive, and sensitive engineering environments.

-

Learn more or request a custom quote:

hot forming elbow machine

Summary & References

The hot forming elbow machine stands as a key pillar in modern pipeline construction. Combining high automation, material versatility, rigorous quality assurance, and field-proven longevity, it delivers strategic value in oil & gas, chemical, water, and power industries worldwide. Advanced vendors like World Steel Material ensure global standard compliance, robust after-sales support, and custom engineering to match any project need.

Industry expertise, certified quality, and global experience make the hot forming elbow machine the first choice for advanced piping projects.

- [TWI Industry Pipe Reports, 2023] Pipe Bending &

Post time: Jul . 29, 2025 22:00