Navigating the Market for High-Performance Casing Pipes

In the demanding sectors of oil & gas, geothermal energy, and advanced water well drilling, the integrity and longevity of well infrastructure hinge critically on the quality of its foundational components. Among these, well casing pipe for sale stands as a paramount element, providing structural support to the wellbore and isolating different geological formations. The global market for casing pipe is experiencing robust growth, driven by increasing energy demands, technological advancements in drilling, and a heightened focus on environmental protection and wellbore integrity. Industry trends indicate a pivot towards materials offering superior corrosion resistance, higher strength-to-weight ratios, and enhanced connection integrity, especially for sour gas environments and deep, high-pressure, high-temperature (HPHT) wells. As operators seek to maximize operational efficiency and minimize downtime, the selection of reliable and durable casing pipe for borewell applications becomes a strategic imperative. This article delves into the technical intricacies, manufacturing excellence, and strategic considerations for procuring premium API 5CT L80/N80/J55/K55 BTC casing and tubing pipes.

The Meticulous Manufacturing Process of Casing Pipe

The production of high-quality casing pipe for sale is a multi-stage process, meticulously controlled to ensure adherence to stringent international standards like API 5CT, ISO 9001, and ANSI. This process guarantees the structural integrity, dimensional accuracy, and material performance required for critical downhole applications.

1. Material Selection and Preparation:

The journey begins with the careful selection of raw materials, primarily high-grade steel billets or seamless tubes. These materials are chosen based on their chemical composition, ensuring the final product possesses the desired mechanical properties such as tensile strength, yield strength, and hardness. Typical steel grades used for API 5CT casing and tubing include J55, K55, N80, L80, P110, and Q125, each designed for specific well conditions. For example, L80 is often selected for its resistance to sulfide stress cracking (SSC) in mildly corrosive environments.

2. Seamless Pipe Production (Mandatory for API 5CT):

- Heating: Steel billets are uniformly heated to precise temperatures, typically around 1200-1300°C, in a rotary hearth furnace.

- Piercing: The heated billet is then pierced by a mandrel over a rolling mill to create a hollow shell, which is the foundational form of the seamless pipe. This forging process ensures a uniform wall thickness and eliminates welds, crucial for high-pressure applications.

- Rolling and Sizing: The hollow shell undergoes multiple passes through rolling mills to achieve the specified outer diameter (OD) and wall thickness. A sizing mill then finely adjusts the pipe dimensions.

3. Heat Treatment:

Heat treatment is critical for developing the desired mechanical properties and microstructure. Depending on the steel grade (e.g., L80, N80), pipes undergo processes such as normalizing, quenching, and tempering. Quenching involves rapid cooling to harden the steel, followed by tempering to improve toughness and ductility, while reducing brittleness. This step significantly enhances the service life and resistance to environmental factors like corrosion.

4. Straightening and End Processing:

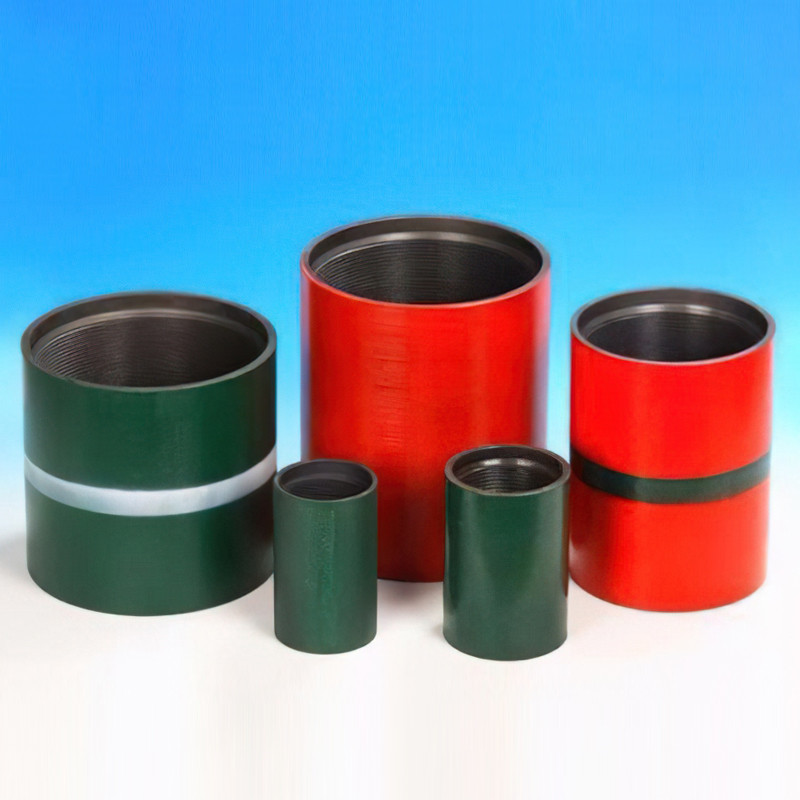

Pipes are straightened to meet dimensional tolerances. The pipe ends are then precisely machined using CNC equipment to create specific thread profiles, such as Buttress Thread Casing (BTC), Long Round Thread (LTC), or Short Round Thread (STC), ensuring robust and leak-proof connections.

5. Non-Destructive Testing (NDT) and Inspection:

Every length of casing pipe undergoes rigorous inspection and NDT as per API 5CT and other relevant standards.

- Visual Inspection: Checking for surface defects, dents, or laminations.

- Dimensional Inspection: Verifying OD, wall thickness, length, and straightness.

- Hydrostatic Testing: Pressurizing the pipe with water to detect leaks and confirm pressure containment capabilities.

- Ultrasonic Testing (UT): Detecting internal flaws, laminations, or wall thickness variations.

- Electromagnetic Inspection (EMI): Identifying longitudinal and transverse imperfections.

- Drift Testing: Ensuring the internal diameter allows passage of drilling tools.

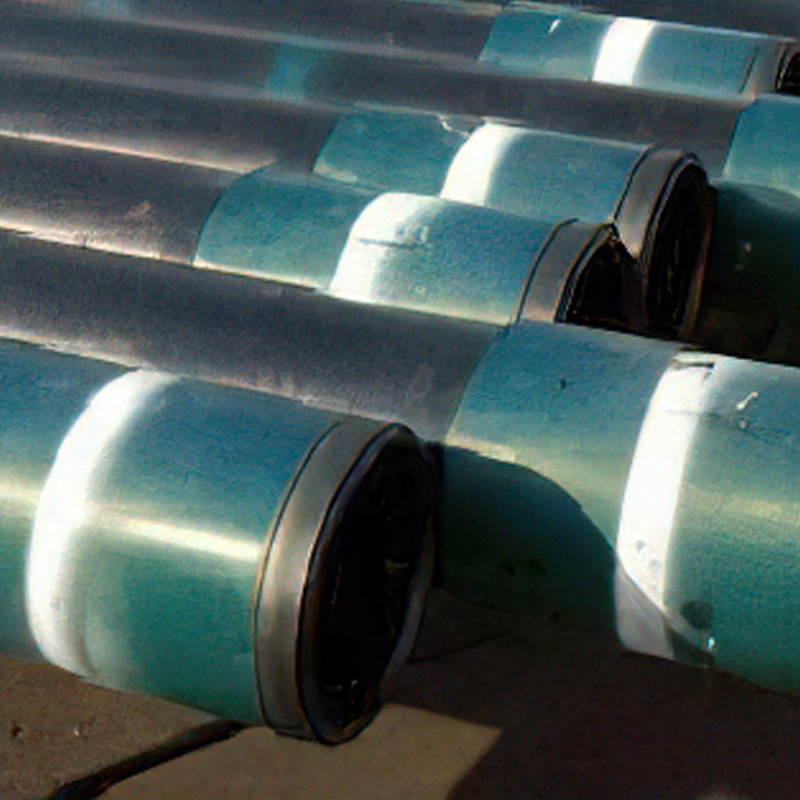

6. Coating and Marking:

Finally, protective coatings (e.g., varnish, anti-corrosion paint) are applied, and pipes are stenciled with relevant information including manufacturer, size, grade, and API monogram. This comprehensive process, from material sourcing to final inspection, ensures that each casing pipe meets the exacting demands of the industry, delivering energy saving benefits through reduced wellbore friction and unparalleled corrosion resistance in challenging environments.

Technical Specifications and Industry Standards

Our API 5CT L80/N80/J55/K55 BTC casing pipe products are engineered to meet and exceed the most rigorous industry standards, providing robust solutions for diverse drilling and production needs. These specifications dictate material composition, mechanical properties, dimensions, and testing protocols, ensuring consistent quality and performance across the industry.

API 5CT Grades Overview:

- J55/K55: General purpose grades suitable for wells with low to medium depths and pressures. K55 has slightly higher minimum tensile strength than J55.

- N80: A medium-strength grade used in various well conditions, offering enhanced performance over J55/K55. Available in N80-1 and N80Q (Quenched & Tempered).

- L80: Often chosen for sour service applications due to its controlled hardness and excellent resistance to sulfide stress cracking (SSC). Available in L80 Type 1, L80 9Cr, and L80 13Cr, with varying levels of corrosion resistance.

- P110/Q125: High-strength grades for deep wells, high pressures, and complex geological formations, offering superior collapse resistance.

Standard Specifications for API 5CT Casing Pipe (Example: 5 1/2" Casing Pipe)

| Parameter | J55 | K55 | N80Q | L80 Type 1 |

|---|---|---|---|---|

| Outer Diameter Range | 4 1/2" to 20" (114.3mm to 508mm) | |||

| Wall Thickness Range | 0.205" to 0.650" (5.21mm to 16.51mm) | |||

| Min. Yield Strength (PSI) | 55,000 | 55,000 | 80,000 | 80,000 |

| Max. Yield Strength (PSI) | 80,000 | 80,000 | 110,000 | 95,000 |

| Min. Tensile Strength (PSI) | 75,000 | 95,000 | 100,000 | 95,000 |

| Connection Type | Buttress Thread Casing (BTC), Long/Short Round Thread (LTC/STC), Premium Connections | |||

| Hardness (HRC Max) | N/A | N/A | N/A | 23 (for SSC resistance) |

This table provides a generalized overview. Specific 5 1/2 casing pipe for sale parameters can vary based on nominal weight per foot and specific manufacturing tolerances. All products comply with API Q1 and ISO 9001 quality management systems, ensuring robust performance and traceability.

Diverse Application Scenarios and Technical Advantages

The versatility and robust performance of our casing pipe for borewell applications extend across a multitude of critical industries, demonstrating significant advantages in demanding environments.

Key Application Sectors:

- Oil and Gas Exploration & Production: Essential for supporting the wellbore, preventing collapse, and isolating different fluid zones. High-strength grades like P110 and Q125 are crucial for deep, unconventional drilling, including shale gas and tight oil. L80 is frequently deployed in H2S-containing (sour) environments to resist sulfide stress cracking, ensuring long-term well integrity.

- Geothermal Energy: With high temperatures and often corrosive geothermal fluids, specialized casing, including L80 13Cr, is vital for long-term operational integrity and energy efficiency in power generation.

- Water Well Drilling: Providing structural support and preventing contamination in potable and agricultural water extraction. Grades like J55 and K55 offer cost-effective and reliable solutions for water well casing.

- Carbon Capture and Storage (CCS): Emerging applications require casing that can withstand the unique pressures and corrosive properties associated with CO2 injection and storage, demanding high integrity and corrosion resistance.

- Mining and Mineral Extraction: Used in exploration and dewatering wells to maintain borewell stability and prevent formation damage.

Technical Advantages:

- Superior Corrosion Resistance: Especially with L80 (Type 1, 9Cr, 13Cr) grades, our casing pipes are specifically designed to resist degradation from corrosive agents like H2S, CO2, and chlorides, common in sour gas wells and geothermal environments. This extends the service life significantly, reducing costly replacements and ensuring system longevity.

- High Strength and Collapse Resistance: Through precise material selection and advanced heat treatment (Quenched & Tempered N80, P110), our casing provides exceptional yield and tensile strength, crucial for withstanding external pressures in deep wells and complex geological strata, preventing wellbore collapse.

- Enhanced Connection Integrity: Buttress Thread Casing (BTC) connections are engineered for high-load applications, offering excellent tensile strength and sealing capabilities. This minimizes leakage risks and ensures the structural continuity of the casing string, vital for well safety and environmental protection.

- Optimized Metallurgy for Energy Efficiency: The smooth internal surface finish and precise dimensional control reduce friction during drilling and production, contributing to energy saving in pumping operations and facilitating efficient fluid flow. The inherent durability also reduces the energy footprint associated with frequent pipe replacement.

- Consistency and Reliability: Adherence to API 5CT and ISO standards, coupled with rigorous NDT, guarantees consistent quality, reducing operational risks and increasing confidence in well construction.

Industry Trends and Market Dynamics

The market for well casing pipe for sale is constantly evolving, shaped by macro-economic factors, technological advancements, and shifting regulatory landscapes. Key trends influencing demand and product development include:

- Increased Unconventional Drilling: The proliferation of shale gas and tight oil plays drives demand for longer, stronger, and more specialized casing strings, often requiring higher-grade materials (P110, Q125) and premium connections.

- Focus on Well Integrity and Safety: Stringent environmental regulations and increased awareness of well integrity failures are pushing operators to invest in higher-quality casing pipe that offers superior burst and collapse resistance, as well as enhanced corrosion mitigation. This includes a greater emphasis on advanced NDT and traceability.

- Digitalization and Automation: The industry is embracing digital technologies for real-time monitoring of casing performance, predictive maintenance, and optimized supply chain management, improving efficiency in the procurement and deployment of casing pipe.

- Advanced Materials and Metallurgy: Ongoing research and development into new steel alloys and heat treatment processes aim to produce casing pipes with even greater strength, ductility, and resistance to extreme temperatures and corrosive agents, extending well life in challenging downhole conditions. This includes advancements in duplex and super duplex steels for ultra-sour service.

- Geographic Shifts in Production: While traditional oil & gas regions remain significant, new exploration and production activities in areas like Africa, South America, and Asia are opening up new markets for casing and tubing suppliers.

Vendor Comparison and Customization Solutions

Selecting the right supplier for casing pipe is as crucial as selecting the right product itself. A reliable vendor offers not just quality products but also extensive technical support, customization capabilities, and strong logistical expertise.

Key Differentiators in Vendor Selection:

| Feature | Premium Supplier (e.g., World Steel Material) | Standard Supplier |

|---|---|---|

| Certifications | API 5CT, API Q1, ISO 9001, CE, NACE MR0175 (for sour service) | Basic ISO 9001, often limited API compliance |

| Product Range | Comprehensive API 5CT grades (J55 to Q125), proprietary connections, specialty alloys | Limited standard grades (J55, N80), basic connections |

| Quality Control | 100% NDT (EMI, UT, Hydrostatic), third-party inspection readiness, full traceability | Batch testing, minimal NDT, less detailed reporting |

| Customization | Tailored lengths, specific coatings, premium connections, specialized metallurgy (e.g., L80 13Cr for specific corrosion needs) | Limited to standard dimensions and grades |

| Technical Support | Application engineering, metallurgical consultation, real-time problem-solving | Basic product information, limited technical expertise |

| Lead Time & Logistics | Optimized supply chain, global distribution network, reliable delivery schedules | Potentially longer lead times, less flexible logistics |

Customized Solutions:

Recognizing that every drilling project presents unique challenges, we offer comprehensive customized solutions for well casing pipe for sale. This includes:

- Tailored Dimensions: Pipes cut to precise lengths to minimize waste and optimize operational efficiency on-site.

- Special Coatings: Internal and external coatings (e.g., epoxy, phenolic) for enhanced corrosion or abrasion resistance in specific downhole conditions.

- Proprietary Connections: Beyond standard BTC, LTC, and STC, we can facilitate premium connections designed for extreme torque, pressure, and sealing capabilities.

- Metallurgical Customization: Adjustments to alloy composition and heat treatment to fine-tune mechanical properties or corrosion resistance for unique well environments (e.g., specific H2S/CO2 concentrations, ultra-HPHT).

- Logistical Flexibility: Specialized packaging, stacking, and shipping arrangements to accommodate remote locations or demanding schedules.

Real-World Application Case Studies

Our commitment to quality and technical excellence is demonstrated through successful deployments in challenging projects worldwide. These case studies highlight the tangible benefits of choosing high-grade API 5CT casing and tubing pipes.

Case Study 1: Deepwater Offshore Gas Field

- Challenge: An operator in the Gulf of Mexico faced extreme pressures (up to 20,000 psi) and high temperatures (350°F / 175°C) in a deepwater sour gas reservoir. The combination of H2S and CO2 required highly corrosion-resistant and ultra-high-strength casing.

- Solution: We supplied 5 1/2" (139.7mm) and 7" (177.8mm) API 5CT L80 13Cr and P110 casing pipe with specialized premium connections. The L80 13Cr offered exceptional resistance to chloride and H2S stress corrosion cracking, while P110 provided the necessary collapse and burst strength for deep sections.

- Outcome: The wells have been in continuous production for over 7 years without any casing-related failures, significantly exceeding the client's initial 5-year operational target. This outcome demonstrated superior wellbore integrity and substantial savings on potential workover costs.

Case Study 2: Geothermal Power Plant Expansion

- Challenge: A geothermal energy project in Southeast Asia required expansion drilling into highly corrosive and high-temperature (up to 250°C) steam reservoirs. Standard carbon steel casing pipe suffered rapid degradation.

- Solution: We provided custom-length 9 5/8" (244.5mm) API 5CT L80 9Cr casing pipe. This specific alloy offered enhanced resistance to the unique chemical composition of the geothermal brine, including high levels of chlorides and non-condensable gases.

- Outcome: The L80 9Cr casing significantly extended the service life of the geothermal wells, reducing maintenance frequency by 40% compared to previous installations. This enhanced operational reliability directly contributed to consistent power generation and improved profitability.

Case Study 3: Large-Scale Water Well Project

- Challenge: A municipal water supply project required drilling numerous large-diameter water wells in a region with varying soil stability. The primary concern was reliable long-term structural support for the borewells and prevention of sediment ingress.

- Solution: We supplied 13 3/8" (339.7mm) and 10 3/4" (273.1mm) API 5CT J55 and K55 casing pipe for borewell applications. The pipes were delivered with customized perforations and slotting as per geotechnical requirements, enabling efficient water intake while filtering out undesirable particulates.

- Outcome: The project successfully established a stable and clean water supply infrastructure. The robust J55/K55 casing ensured excellent structural integrity, and the customized perforations maximized well efficiency, delivering consistent water flow and extending the operational life of the wells.

Trustworthiness and Support: Your Partner in Success

Establishing long-term partnerships built on trust and reliability is paramount in the B2B sector. We are committed to transparency, quality assurance, and comprehensive customer support for every well casing pipe for sale we provide.

Frequently Asked Questions (FAQ):

- Q1: What certifications do your API 5CT casing and tubing pipes hold?

- A1: Our products are manufactured under strict adherence to API 5CT, API Q1, and ISO 9001 standards. We also comply with NACE MR0175/ISO 15156 for sour service applications, ensuring suitability for corrosive environments.

- Q2: What is the typical lead time for an order?

- A2: Lead times vary depending on pipe grade, size, quantity, and customization requirements. For standard API 5CT grades and sizes, lead times typically range from 4 to 8 weeks. Specialized or large orders may require longer, but we always provide a precise timeline upon quotation and work diligently to meet project deadlines.

- Q3: Do you offer warranty on your products?

- A3: Yes, all our API 5CT casing and tubing pipes come with a comprehensive warranty against manufacturing defects and non-conformance to specified API and agreed-upon standards. Our commitment to quality ensures product reliability under specified operating conditions.

- Q4: Can you provide technical support for selecting the right casing for my project?

- A4: Absolutely. Our team of experienced metallurgical and application engineers is available to provide detailed technical consultation, assisting you in selecting the optimal casing grade, size, and connection type based on your specific well parameters, geological conditions, and operational requirements.

Lead Time & Fulfillment:

Our streamlined manufacturing processes and robust supply chain management enable us to offer competitive lead times. From order confirmation to delivery, our logistics team ensures efficient and reliable fulfillment, including specialized packaging and transportation options to remote locations globally. We maintain strategic inventory levels for common casing pipe grades to expedite urgent requirements.

Warranty and After-Sales Support:

We stand by the quality of our products with a robust warranty program. Beyond the sale, our dedicated after-sales support team is available to address any technical inquiries, operational challenges, or provide assistance with future project phases. Our commitment extends to providing comprehensive documentation, material test reports (MTRs), and full traceability for every pipe supplied, ensuring peace of mind and operational continuity for our clients.

Conclusion

The selection of appropriate casing and tubing pipe is a critical determinant of well integrity, operational efficiency, and environmental safety across various industries. By offering API 5CT L80/N80/J55/K55 BTC casing pipe manufactured to the highest standards, backed by rigorous testing, expert technical support, and flexible customization, we aim to be your trusted partner in navigating complex drilling and production challenges. Our comprehensive solutions ensure that your projects benefit from superior performance, extended service life, and optimized total cost of ownership.

References:

- American Petroleum Institute (API). API Specification 5CT: Specification for Casing and Tubing. 10th Edition.

- International Organization for Standardization (ISO). ISO 9001: Quality management systems – Requirements.

- National Association of Corrosion Engineers (NACE). NACE MR0175 / ISO 15156: Petroleum and natural gas industries - Materials for use in H2S-containing environments in oil and gas production.

- Wang, P., Guo, W., Liu, Z., & Gao, D. (2018). Research on the mechanical properties of API 5CT casing and tubing under complex loading. Journal of Petroleum Science and Engineering, 169, 363-370.

- Cai, X., Peng, X., Liu, Y., & Dong, F. (2019). Evolution of material properties of casing steels and its application in unconventional oil and gas development. Engineering Failure Analysis, 96, 442-452.

Post time: Sep . 15, 2025 12:00