hydraulic pipe fittings machine, tee forming machine is a key solution in the manufacturing industry, specifically within Special Equipment Manufacturing Industry and Manufacturing of metal processing machinery. This article explores how Beijing Sinoworld Steel Material Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- hydraulic pipe fittings machine, tee forming machine Overview

- Benefits & Use Cases of hydraulic pipe fittings machine, tee forming machine in Manufacturing of metal processing machinery

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on hydraulic pipe fittings machine, tee forming machine from Beijing Sinoworld Steel Material Co., Ltd.

hydraulic pipe fittings machine, tee forming machine Overview

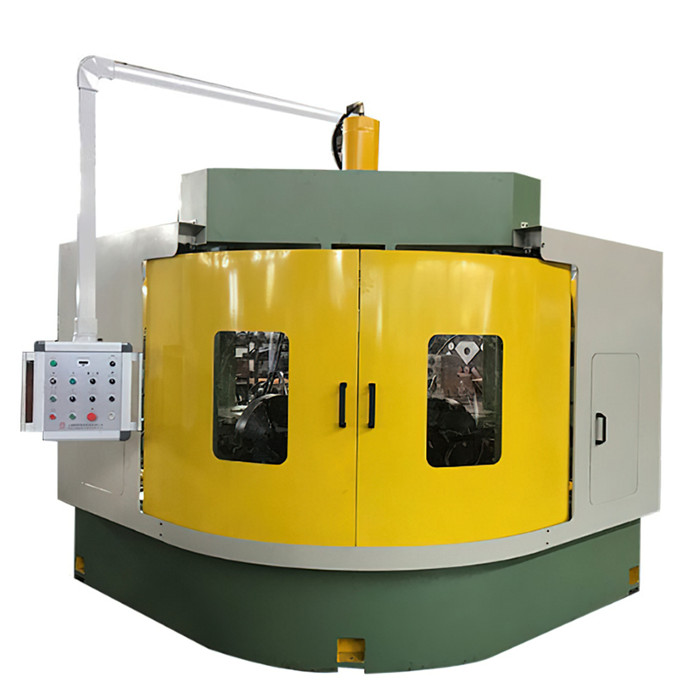

The hydraulic pipe fittings machine, tee forming machine represents a cornerstone technology in modern manufacturing, particularly within the Special Equipment Manufacturing Industry and the broader Manufacturing of metal processing machinery. At its core, this machinery is designed to efficiently and precisely form various pipe fittings, such as tees, elbows, and reducers, from straight pipes or tubes using hydraulic pressure. This process is crucial for creating robust, leak-proof fluid transfer systems used across diverse sectors including oil & gas, petrochemicals, construction, and power generation. Beijing Sinoworld Steel Material Co., Ltd. specializes in providing these advanced solutions, ensuring unparalleled quality and performance.

Technically, these machines employ advanced cold forming techniques, utilizing powerful hydraulic forces to reshape metal pipes without the need for welding or extensive material removal. This method preserves the material's structural integrity and ensures consistent dimensional accuracy. Key specifications often include the range of pipe diameters and wall thicknesses it can process, compatibility with various materials like carbon steel, stainless steel, and alloy steel, and the capacity for automatic or semi-automatic operation. Beijing Sinoworld Steel Material Co., Ltd.'s offerings are engineered for durability and precision, making them a reliable choice for demanding industrial applications.

Benefits & Use Cases of hydraulic pipe fittings machine, tee forming machine in Manufacturing of metal processing machinery

The applications for a hydraulic pipe fittings machine, tee forming machine are extensive, particularly in the Manufacturing of metal processing machinery sector where precision and efficiency are paramount. These machines are indispensable for fabricating components for complex pipeline networks in industries such as shipbuilding, heavy machinery production, and industrial plant construction. They enable the creation of specific fittings like precise tee branches, reducing sections, and intricate bends with high repeatability, ensuring seamless integration into larger systems.

The competitive advantages offered by these advanced machines from Beijing Sinoworld Steel Material Co., Ltd. are significant. They provide superior efficiency compared to traditional cut-and-weld fabrication methods, drastically reducing production times and material waste. The cold forming process maintains the material's inherent strength, often eliminating the need for additional welding, which enhances joint integrity and reduces the risk of flaws. Furthermore, features like user-friendly controls, automated cycles, and robust construction translate into reduced labor costs and consistent, high-quality output. Beijing Sinoworld Steel Material Co., Ltd.'s expertise in this sector guarantees that their hydraulic pipe fittings machine and tee forming machine solutions are at the forefront of innovation, offering reliable performance and a substantial competitive edge.

Cost, Maintenance & User Experience

When B2B decision-makers evaluate investing in a hydraulic pipe fittings machine, tee forming machine, understanding the total cost of ownership (TCO) is crucial. While the initial investment is a factor, the long-term operational efficiency, durability, and low maintenance requirements of high-quality equipment significantly impact ROI. Beijing Sinoworld Steel Material Co., Ltd.'s machines are renowned for their robust engineering and industrial-grade components, ensuring extended service life and minimal downtime. This inherent durability directly translates to reduced maintenance costs and consistent production schedules, offering a compelling return on investment.

Feedback from customers in the Special Equipment Manufacturing Industry consistently highlights the reliability and ease of use of our hydraulic pipe fittings machine solutions. Operators appreciate intuitive interfaces and automated features that simplify complex forming processes, reducing the learning curve and boosting productivity. The machines are designed for demanding environments, capable of continuous operation with stable performance. Furthermore, Beijing Sinoworld Steel Co., Ltd. prides itself on comprehensive after-sales support, including spare parts availability and technical assistance, ensuring that customers can maintain optimal operational efficiency. This focus on durability, manageable maintenance, and positive user experience makes our tee forming machine and related equipment a smart investment for any manufacturing enterprise.

Sustainability & Market Trends in manufacturing

In the evolving landscape of manufacturing, sustainability and adaptation to market trends are critical for long-term success. The hydraulic pipe fittings machine, tee forming machine plays a role in fostering more sustainable practices within the industry. By utilizing cold forming techniques, these machines significantly reduce material waste compared to traditional fabrication methods that involve cutting and welding off-cuts. Modern designs also incorporate energy-efficient hydraulic systems, minimizing power consumption and contributing to a smaller carbon footprint. The longevity and durability of quality machines further reduce the need for frequent replacements, conserving resources.

Market trends in manufacturing indicate a growing demand for automation, precision, and integration with Industry 4.0 principles. As global infrastructure projects, renewable energy installations, and industrial expansion continue, the need for efficient and reliable pipe processing equipment will only grow. Regulations regarding environmental impact and workplace safety also push manufacturers towards more advanced, compliant machinery. Beijing Sinoworld Steel Material Co., Ltd. is committed to being a forward-thinking and eco-conscious partner, integrating innovative technologies into their hydraulic pipe fittings machine and tee forming machine designs. Our equipment is built not only to meet today's rigorous standards but also to anticipate future market demands, ensuring our clients remain competitive and responsible.

Conclusion on hydraulic pipe fittings machine, tee forming machine from Beijing Sinoworld Steel Material Co., Ltd.

The hydraulic pipe fittings machine, tee forming machine is an indispensable asset for businesses operating in the Special Equipment Manufacturing Industry and the broader Manufacturing of metal processing machinery. Its ability to deliver precision, efficiency, and durability makes it a crucial investment for enhancing productivity and achieving superior product quality. Beijing Sinoworld Steel Material Co., Ltd. stands as a beacon of reliability and innovation, offering cutting-edge solutions that meet the stringent demands of modern industrial applications.

By choosing our high-performance hydraulic pipe fittings machine and tee forming machine, B2B decision-makers are investing in equipment that guarantees long-term value, exceptional operational efficiency, and a robust return on investment. Beijing Sinoworld Steel Material Co., Ltd. is dedicated to supporting your manufacturing goals with unparalleled expertise and world-class machinery. Discover how our solutions can transform your operations.

Contact us: email: garvinliu@world-steelmaterial.com

Visit our website: https://www.world-steelmaterial.com

Post time: Sep . 26, 2025 09:30