The Critical Role of Anti-Corrosion Pipe in Industrial Infrastructure

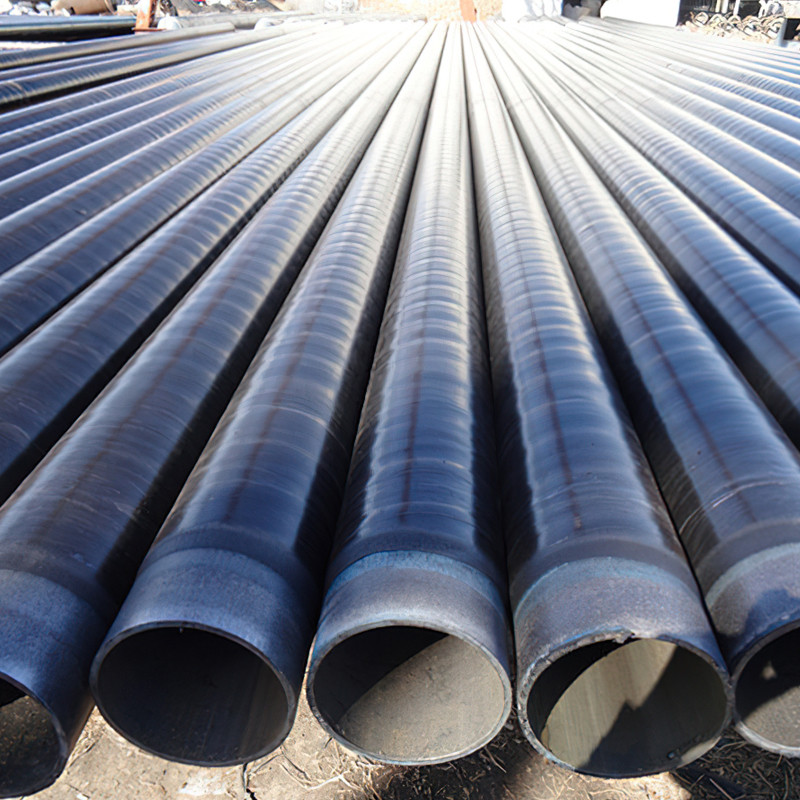

In industrial environments, the longevity and reliability of piping systems are paramount. Exposure to aggressive media, fluctuating temperatures, and abrasive conditions can lead to severe corrosion, compromising structural integrity, causing operational disruptions, and incurring significant economic losses. This necessitates the widespread adoption of specialized anti corrosion pipe solutions, designed to withstand these challenges and ensure sustained performance.

Our focus today is on advanced anti-corrosion pipe technologies, specifically those incorporating 3-Layer Polyethylene (3LPE), 3-Layer Polypropylene (3LPP), and Fusion Bonded Epoxy (FBE) coatings. These state-of-the-art coatings represent the forefront of material science in protecting vital infrastructure across diverse sectors, including petrochemical, oil & gas, water treatment, and mining.

Current Industry Trends in Anti-Corrosion Pipe Technology

The demand for robust corrosion protection continues to grow, driven by aging infrastructure, the exploration of new energy sources in challenging environments, and stricter environmental regulations. Key trends shaping the anti corrosion pipe market include:

- Sustainable Coatings: Increasing emphasis on environmentally friendly coating processes and materials with lower VOC emissions.

- Advanced Testing & Monitoring: Development of intelligent inspection techniques, including IoT-enabled sensors for real-time corrosion monitoring.

- High-Temperature & High-Pressure Applications: Innovations in coatings like 3LPP for enhanced performance in extreme operating conditions, particularly in offshore and deep-sea exploration.

- Hybrid Coating Systems: Exploration of multi-layer hybrid systems combining properties of different coatings for optimized performance and cost-effectiveness.

- Standardization and Certification: Continuous refinement of international standards (e.g., ISO 21809, NACE SP0169) to ensure product quality and reliability.

These trends reflect a collective industry effort to extend the service life of pipelines, minimize maintenance costs, and enhance safety across critical infrastructure projects.

Detailed Process Flow: Manufacturing Anti-Corrosion Pipe Coatings

The manufacturing of anti corrosion steel pipe with advanced coatings involves several meticulously controlled stages to ensure optimal adhesion, uniformity, and protective properties. The primary goal is to create a durable barrier against environmental degradation.

General Process for 3LPE/3LPP/FBE Coating:

-

Pipe Inspection & Preparation:

Raw pipe inspection (visual, dimensional, NDT). Cleaning to remove oil, grease, and loose debris. This often involves solvent cleaning or high-pressure water washing.

-

Surface Blasting:

Pipes undergo abrasive blast cleaning (e.g., grit or shot blasting) to achieve a specified surface roughness profile (typically Sa 2.5 or Sa 3 according to ISO 8501-1) and remove mill scale and rust. This rough surface is crucial for mechanical interlocking and good adhesion of the coating.

-

Dust Removal & Heating:

After blasting, dust and abrasive particles are removed using brushes and vacuum systems. The pipe is then pre-heated to the specific temperature required for coating application (e.g., 200-230°C for FBE, 180-220°C for 3LPE/3LPP).

-

Coating Application (Specific to Coating Type):

- FBE (Fusion Bonded Epoxy): Epoxy powder is electrostatically applied to the hot pipe. The heat causes the powder to melt, flow, and cure, forming a uniform, tough film.

-

3LPE/3LPP (3-Layer Polyethylene/Polypropylene): This involves three layers:

- Layer 1 (FBE): A thin layer of Fusion Bonded Epoxy (FBE) primer is applied for excellent adhesion to steel and enhanced corrosion protection.

- Layer 2 (Adhesive): A copolymer adhesive layer is extruded over the FBE, chemically bonding the FBE to the outer polyolefin layer.

- Layer 3 (Polyethylene/Polypropylene): An outer layer of extruded medium or high-density polyethylene (for 3LPE) or polypropylene (for 3LPP) provides mechanical protection and weather resistance.

-

Cooling & Curing:

After application, the coated pipe is cooled, typically by water spray, to solidify the coating. FBE also undergoes a specific curing process to achieve its full protective properties.

-

Quality Control & Inspection:

Stringent quality checks are performed, including holiday detection (spark testing for pinholes), coating thickness measurement, adhesion testing (peel test), impact resistance, cathodic disbondment tests, and visual inspection. Compliance with standards like ISO 21809, DIN 30670, CAN/CSA Z245.21, and NACE is verified.

-

End Cut Back & Marking:

Pipe ends are typically left uncoated (cut back) to facilitate welding. The finished pipes are marked with essential information (e.g., coating type, batch number, date).

The careful execution of each step ensures the long-term integrity and performance of the anti corrosion pipe coating system.

Technical Specifications and Parameters

Understanding the technical parameters of anti corrosion pipe is crucial for selecting the appropriate product for specific applications. The choice of coating depends on operating temperature, environmental conditions, and mechanical stress requirements.

Typical Product Specifications: ANTI-CORROSION PIPE (3LPE/3LPP/FBE)

| Parameter | 3LPE Coating | 3LPP Coating | FBE Coating |

|---|---|---|---|

| Base Pipe Material | Carbon Steel, Alloy Steel | Carbon Steel, Alloy Steel | Carbon Steel, Alloy Steel |

| Pipe Diameter Range (OD) | DN80 - DN1600 (3" - 64") | DN80 - DN1600 (3" - 64") | DN25 - DN1600 (1" - 64") |

| Max Operating Temperature | -40°C to +80°C | -40°C to +110°C | -40°C to +90°C |

| Minimum Coating Thickness (mm) | 1.8 - 4.5 (based on OD) | 1.8 - 4.5 (based on OD) | 0.3 - 0.7 (300-700 microns) |

| Adhesion (ASTM D4541) | >20 N/cm (peel test) | >25 N/cm (peel test) | >10 MPa (pull-off) |

| Impact Resistance (J/mm) | >5 J/mm (typically @ 23°C) | >6 J/mm (typically @ 23°C) | ~1.5 - 2.5 J/mm |

| Cathodic Disbondment (mm) | <7 mm (ISO 21809-1 @ 28 days) | <7 mm (ISO 21809-1 @ 28 days) | <7 mm (ISO 21809-1 @ 28 days) |

| Water Absorption (%) | <0.1% | <0.05% | <0.05% |

| Standards Compliance | ISO 21809-1, DIN 30670, CAN/CSA Z245.21 | ISO 21809-1, DIN 30678, CAN/CSA Z245.21 | ISO 21809-2, AWWA C213, API RP 5L7 |

These specifications are generalized and may vary based on specific project requirements and manufacturer capabilities. We encourage consultation for tailored solutions.

Application Scenarios and Industry Benefits

The versatility and robust protection offered by anti corrosion pipe make it indispensable across a multitude of heavy industries. Its application directly translates into enhanced operational efficiency, reduced maintenance, and improved safety.

-

Oil and Gas Industry (Onshore & Offshore):

Transporting crude oil, natural gas, and refined products through diverse terrains and challenging marine environments. Anti corrosion pipe is crucial for preventing external corrosion from soil, seawater, and internal corrosion from aggressive media (e.g., H₂S, CO₂). The coatings ensure a service life of 30-50 years, significantly reducing pipeline failures and environmental risks.

-

Water Supply & Drainage Systems:

Ensuring the safe and clean delivery of potable water and efficient wastewater removal. Coatings prevent pipe degradation, preserving water quality and minimizing leakage due to rust. Anti corrosion paint for copper pipe is often used in smaller, internal plumbing systems, while robust coatings are essential for large-scale municipal and industrial water pipelines.

-

Petrochemical and Chemical Processing Plants:

Handling corrosive chemicals and hydrocarbons at varying temperatures and pressures. Coated pipes resist chemical attack, contributing to plant safety and operational continuity. The robust protection supports higher throughput and reduces downtime associated with pipe replacement.

-

Mining and Slurry Transportation:

Transporting abrasive slurries and corrosive mine water. The mechanical toughness of 3LPE/3LPP coatings, combined with their corrosion resistance, helps withstand both abrasive wear and chemical degradation, extending pipeline life in highly demanding environments.

In each scenario, the underlying advantage is the significant reduction in life-cycle costs, enhanced safety, and environmental protection due to minimized leakages and extended pipeline service life.

Technical Advantages of 3LPE, 3LPP, and FBE Coatings

Each coating system offers distinct benefits, making them suitable for different operational challenges. Our anti corrosion pipe coating solutions are engineered for optimal performance.

Comparative Advantages:

| Feature | 3LPE Coating | 3LPP Coating | FBE Coating |

|---|---|---|---|

| Corrosion Resistance | Excellent, especially against soil chemicals and moisture. | Superior, excellent resistance to hot water and cathodic disbondment. | Excellent, forms a strong barrier against corrosion. |

| Mechanical Protection | Very High: Excellent impact, abrasion, and penetration resistance. | Exceptional: Higher mechanical strength and hardness than 3LPE. | Good: Sufficient for typical handling, but less than polyolefin layers. |

| Operating Temperature | Up to 80°C | Up to 110°C (ideal for high-temp applications) | Up to 90°C |

| Adhesion to Steel | Excellent, due to FBE primer and adhesive layer. | Excellent, strong chemical bond with steel via FBE primer. | Outstanding, strong chemical bond at molecular level. |

| Flexibility | Good, suitable for bending and varying terrain. | Moderate, slightly less flexible than 3LPE due to higher hardness. | Good, maintains integrity during bending. |

| Cathodic Disbondment | Very Good, resists disbondment under cathodic protection. | Excellent, superior performance in high-temperature environments. | Excellent, strong resistance to disbondment. |

These robust characteristics contribute to significantly extended pipeline lifespans, minimizing the need for costly repairs and replacements, and reducing environmental impact through leak prevention. The selection of the optimal coating depends on a thorough analysis of operational parameters and environmental conditions.

Vendor Comparison and Selection for Anti-Corrosion Pipe

Choosing the right supplier for anti corrosion pipe is as critical as selecting the coating itself. Reputable 3lpe coating suppliers and other coating specialists differentiate themselves through a combination of technical expertise, quality assurance, and service capabilities.

Key Considerations for Vendor Selection:

- Certifications and Compliance: Verify adherence to international standards (e.g., ISO 9001, API, NACE, DNV). Our products conform to global industry benchmarks, ensuring reliability.

- Experience and Track Record: Assess the vendor's years of service and portfolio of successfully completed projects, particularly in demanding environments. Our company boasts extensive experience and a robust track record.

- Manufacturing Capabilities: Evaluate facility capacity, advanced equipment, and the ability to handle diverse pipe sizes and coating types (3LPE, 3LPP, FBE).

- Quality Control Procedures: Inquire about their in-house testing facilities, personnel qualifications, and comprehensive inspection protocols throughout the production process.

- Customization Options: The ability to provide tailored solutions for specific project parameters, including unique coating thickness, materials, or pipe dimensions.

- Logistics and Support: Timely delivery, robust packaging, and responsive post-sales support are crucial for large-scale projects.

A reliable vendor acts as a strategic partner, ensuring that your investment in anti corrosion pipe delivers maximum long-term value.

Customized Solutions for Diverse Project Requirements

Recognizing that no two projects are identical, we offer highly customized anti corrosion pipe solutions. Our engineering team collaborates closely with clients to understand specific environmental challenges, operational parameters, and regulatory requirements.

Customization extends to various aspects:

- Coating Thickness: Tailored thickness for enhanced protection in abrasive or highly corrosive environments.

- Pipe Dimensions: Production of coated pipes in non-standard diameters or lengths to minimize field welds.

- End Preparation: Specific cut-back lengths or beveling as per project welding specifications.

- Specialized Coatings: Blended polyolefin compounds for specific temperature ranges or chemical resistances.

- Logistical Solutions: Custom packaging, transportation, and onsite support for remote or complex project locations.

This bespoke approach ensures that each anti corrosion pipe solution is perfectly aligned with the project's unique demands, maximizing performance and cost-efficiency.

Application Case Study: High-Pressure Gas Pipeline in Arid Environment

Project Overview: A major energy company required a new high-pressure gas transmission pipeline spanning 300 km through an arid desert region, characterized by extreme temperature fluctuations, highly abrasive sand, and corrosive soil conditions. The pipeline was critical for national energy supply, demanding a minimum service life of 40 years without significant maintenance.

Challenge: The primary challenges were severe external corrosion due to saline soil, high UV exposure, and mechanical damage from abrasive sand during installation and operation. Internal corrosion was also a concern due to sour gas content.

Solution: After extensive consultation and analysis of environmental data, we recommended a 3LPE anti corrosion pipe system for the external protection. The pipe diameter varied from 24" to 36" (DN600-DN900) with a specialized internal FBE coating for sour gas resistance.

- The 3LPE coating provided exceptional mechanical protection against abrasion and impact, crucial for the desert environment.

- Its high dielectric strength and excellent adhesion ensured long-term cathodic disbondment resistance, even in the highly corrosive soil.

- The internal FBE coating formed a tough barrier against H₂S and CO₂, mitigating internal corrosion risks.

- All pipes underwent rigorous testing, including high-voltage holiday detection, adhesion, and cathodic disbondment tests, exceeding ISO 21809-1 and NACE standards.

Outcome: The project was delivered on schedule, with the coated pipes demonstrating superior performance during and after installation. The client reported significant confidence in the pipeline's projected 50-year service life, attributed to the robust and tailor-made anti corrosion pipe coating solution. This minimized the need for expensive post-installation inspections and repairs, resulting in substantial operational savings and enhanced energy security.

Trustworthiness: FAQ, Lead Time, Warranty & Support

Frequently Asked Questions (FAQ)

Q1: What is the typical service life of an anti corrosion pipe with 3LPE coating?

A1: Under normal operating conditions and proper installation, 3LPE coated pipes are designed for a service life of 30-50 years, often exceeding this with adequate cathodic protection.

Q2: Can FBE coating be used for high-temperature applications?

A2: Standard FBE is suitable for temperatures up to 90°C. For higher temperatures, specialized high-temperature FBE (HT-FBE) or 3LPP coatings are recommended.

Q3: How are coating damages repaired in the field?

A3: Minor damages can be repaired using specialized repair kits, typically involving liquid epoxy or heat-shrink sleeves, ensuring the integrity of the anti corrosion pipe coating is maintained.

Lead Time and Fulfillment

Our lead times vary based on pipe dimensions, coating type, order volume, and current production schedules. Typically, standard orders can be fulfilled within 4-8 weeks. For large-scale projects or custom specifications, we provide a detailed project timeline upon request, ensuring transparent communication and timely delivery. We maintain robust supply chain management to minimize delays.

Warranty Commitments

We stand by the quality of our anti corrosion pipe products. All coated pipes are supplied with a comprehensive warranty covering material defects and coating adhesion under specified operating conditions. Specific warranty terms are provided with each quotation and conform to industry standards, reflecting our commitment to product excellence and customer satisfaction.

Customer Support and After-Sales Service

Our commitment extends beyond delivery. We offer dedicated customer support, including technical assistance for installation, field repair guidance, and expert advice on optimizing pipeline performance. Our team of experienced engineers is available to address any queries or challenges that may arise throughout the project lifecycle, ensuring seamless integration and long-term reliability of our anti corrosion pipe solutions.

Authoritative References and Standards

Our anti corrosion pipe products and processes strictly adhere to recognized international standards and certifications, demonstrating our commitment to quality, safety, and environmental responsibility:

- ISO 9001: Quality Management System certification.

- ISO 21809-1 / DIN 30670 / CAN/CSA Z245.21: Standards for external polyethylene coatings for pipelines.

- ISO 21809-2 / AWWA C213 / API RP 5L7: Standards for fusion-bonded epoxy coatings for pipelines.

- ISO 21809-3 / DIN 30678: Standards for external polypropylene coatings for pipelines.

- NACE SP0169: Control of External Corrosion on Underground or Submerged Metallic Piping Systems.

- API 5L: Specification for Line Pipe, ensuring base pipe material quality.

These certifications validate our expertise and the reliability of our products, ensuring that clients receive solutions that meet the highest industry benchmarks.

Citations

- J. A. K. W. J. R. L. R. L. M. G. G. J. L. A. E. A. W. C. L. C. C. M. J. W. M. M. W. T. W. M. X. M. Y. Z. (2018). Pipeline Coating Systems. In: Pipeline Inspection and Integrity Management. Elsevier. pp. 289-325.

- NACE International. (2018). NACE SP0169-2013: Control of External Corrosion on Underground or Submerged Metallic Piping Systems. NACE International.

- ISO. (2016). ISO 21809-1: Petroleum and natural gas industries — External coatings for buried or submerged pipelines used in pipeline transportation systems — Part 1: Polyolefin coatings (3-layer PE and 3-layer PP). International Organization for Standardization.

- American Water Works Association. (2014). AWWA C213-14: Standard for Fusion-Bonded Epoxy Coating for the Interior and Exterior of Steel Water Pipes. AWWA.

- American Petroleum Institute. (2020). API RP 5L7: Recommended Practice for Unprimed External Fusion Bonded Epoxy Coating of Line Pipe. API Publishing.

Post time: Sep . 19, 2025 10:50