Anti Corrosion Pipe is a key solution in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of pipes and fittings. This article explores how Beijing Sinoworld Steel Material Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Anti Corrosion Pipe Overview

- Benefits & Use Cases of Anti Corrosion Pipe in Manufacturing of pipes and fittings

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Anti Corrosion Pipe from Beijing Sinoworld Steel Material Co., Ltd.

Anti Corrosion Pipe Overview

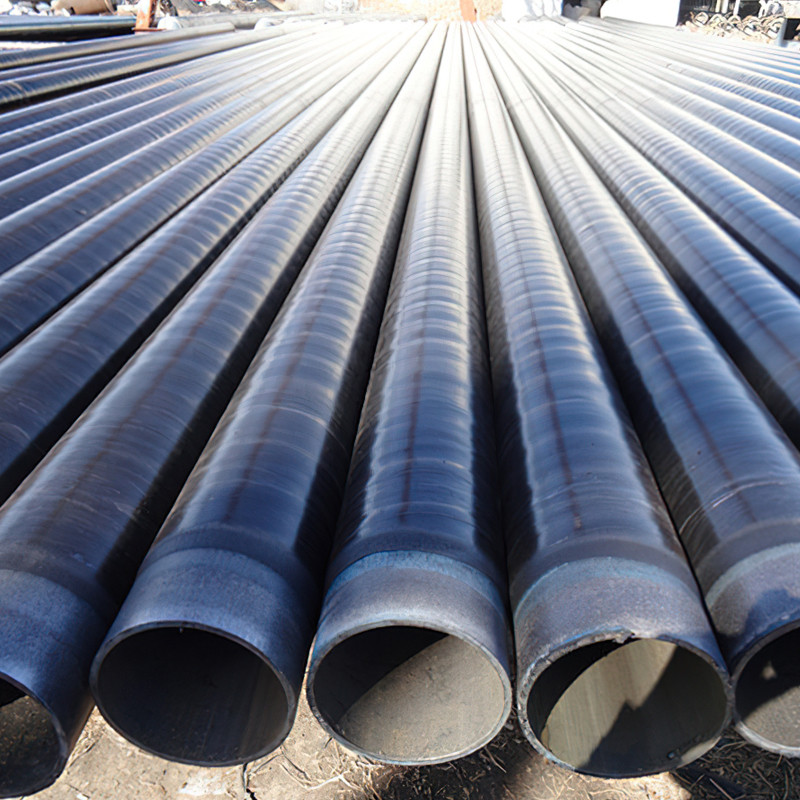

In corrosive service environments, an Anti Corrosion Pipe is engineered to resist moisture, chemicals, soil stress, and temperature cycles that typically degrade unprotected steel. For B2B decision makers in Fabricated metal products and the Manufacturing of pipes and fittings, the right anti corrosion pipe coating is central to lifecycle performance and compliance. Beijing Sinoworld Steel Material Co., Ltd. manufactures anti corrosion steel pipe with industry-proven systems such as 3LPE, 3LPP, and FBE to meet demanding cross-country pipeline, plant piping, and municipal water specifications.

- Technical background: 3LPE (fusion-bonded epoxy + copolymer adhesive + polyethylene) offers excellent cathodic disbondment resistance and impact strength, with typical total thickness 1.8–3.7 mm depending on class and diameter. 3LPP substitutes polypropylene for higher operating temperatures. FBE (single- or dual-layer) provides robust adhesion and a tough dielectric barrier.

- Manufacturability: Pipes can be produced to common project requirements (for example, API 5L grade pipes with external coatings manufactured to widely applied coating standards) and tested via holiday detection, peel strength, and impact tests per project specification.

- As reliable 3LPE coating suppliers, Beijing Sinoworld combines surface preparation, automated coating lines, and QC traceability to deliver consistent performance and on-time delivery for midstream, waterworks, and industrial clients.

Benefits & Use Cases of Anti Corrosion Pipe in Manufacturing of pipes and fittings

In fabrication shops and field projects, coated pipe integrates seamlessly with bends, elbows, tees, and flanged spools. Typical applications include oil and gas transmission, city gas distribution, industrial water and slurry lines, firewater networks, district heating/cooling, and plant interconnects. For tie-ins and small-diameter utilities, anti corrosion paint for copper pipe can complement coated steel networks at equipment interfaces, supporting holistic corrosion protection strategies across mixed materials.

- Key benefits: superior adhesion and dielectric strength, high impact/abrasion resistance, low water permeability, and compatibility with cathodic protection. Field joints can be finished with compatible sleeves or liquid epoxies matched to the original anti corrosion pipe coating.

- Competitive advantages: broad size range, tailored coating thickness by service class, and documented inspection (surface profile, DFT, holiday test) reduce rework and accelerate hydrotest and commissioning timelines.

- Beijing Sinoworld Steel Material Co., Ltd. provides engineering support for coating selection (FBE vs. 3LPE vs. 3LPP), joint protection, and handling/transport best practices, helping EPCs and fabricators minimize damage, waste, and delays.

Cost, Maintenance & User Experience

Total cost of ownership favors coated solutions. While anti corrosion steel pipe has a higher initial purchase price than bare pipe, it reduces coating repairs, mitigates corrosion-related leaks, and extends service life—lowering OPEX and unplanned downtime. Many owners evaluate ROI by comparing life-cycle costs over 20–30 years; with fewer interventions and simplified cathodic protection, the payback typically occurs early in operation for buried or submerged lines.

- Maintenance considerations: proper storage/handling to avoid coating damage, holiday surveys before backfill, compatible field-joint systems, and periodic CP monitoring. FBE systems are readily repairable on site, streamlining punch-list closure.

- User feedback from the fabricated metal products sector highlights faster fabrication fit-up due to consistent bevel protection, fewer NCRs tied to coating holidays, and shorter commissioning cycles thanks to documented QC from the coating line.

Sustainability & Market Trends in manufacturing

Sustainability in pipeline and plant infrastructure is increasingly measured by durability, leak prevention, and embodied carbon per service year. Powder systems like FBE minimize VOC emissions during application, while long-life barrier systems such as 3LPE/3LPP reduce premature replacements, supporting circularity through extended asset life. As environmental regulations and integrity management programs tighten, robust anti corrosion pipe coating strategies help owners meet compliance while protecting communities and ecosystems.

- Market trends: investment in water and wastewater networks, district energy, and integrity upgrades for oil/gas lines; increasing attention to coating compatibility with cathodic protection and trenchless installation stresses; and growing demand for experienced 3LPE coating suppliers who can support complex logistics and documentation.

- Beijing Sinoworld Steel Material Co., Ltd. advances these goals with continuous process improvement, meticulous QA, and customer guidance on best practices—from coating selection to end-of-life recycling pathways for steel assets—positioning your projects for resilient, low-risk performance.

Conclusion on Anti Corrosion Pipe from Beijing Sinoworld Steel Material Co., Ltd.

For manufacturers and EPCs in Fabricated metal products and the Manufacturing of pipes and fittings, specifying Anti Corrosion Pipe is a strategic decision that safeguards uptime, compliance, and budget. With proven 3LPE/3LPP/FBE options, expert guidance, and rigorous QC, Beijing Sinoworld Steel Material Co., Ltd. delivers durable, fit-for-purpose solutions from mill to site.

- Recap: optimized barrier protection, streamlined fabrication, and lower life-cycle costs.

- Reputation: dependable partner for anti corrosion steel pipe and coatings across sectors.

- Strong CTA: Contact us: email: garvinliu@world-steelmaterial.com — Visit our website: https://www.world-steelmaterial.com

Post time: Nov . 10, 2025 07:40