Industry Overview & Market Trends: Seamless Tubing Evolution

The global seamless pipe market was valued at USD 215.36 billion in 2022 and is projected to reach USD 271.12 billion by 2028, growing at a CAGR of 3.8%. Demand for seamless steel pipe is propelled by the rising needs in oil & gas, chemical processing, water transmission, energy generation, and structural applications. Among advanced grades, 17 4 seamless tubing for sale stands out for its high-strength stainless alloy composition (17% chromium, 4% nickel precipitation hardening steel), making it ideal for hostile, high-pressure environments.

Technical Parameters: 17 4 Seamless Tubing for Sale Specification Table

| Parameter | Specification | Industry Standard | Typical Value |

|---|---|---|---|

| Material Grade | 17-4 PH (UNS S17400, ASTM A564) | ASTM A312, API 5L PSL1/PSL2 | Precipitation Hardened Stainless Steel |

| Dimensions | OD: 1/8"-12", Wall: Sch5 - Sch160 | ANSI B36.10, B36.19 | Customized |

| Yield Strength | ≥ 105 ksi (724 MPa) | ISO 6892-1 | 130-150 ksi typical |

| Tensile Strength | ≥ 125 ksi (862 MPa) | ISO 6892-1 | 135-172 ksi |

| Corrosion Resistance | Excellent | ASTM A262 Practice E | Pitting / Crevice Resistant |

| Operating Temperature | -50°C to 600°C | API 5L | - |

| Certifications | API, ISO 9001:2015, PED | 3.1 MTC, NACE MR0175 | Yes |

| Surface Finish | Annealed, Pickled, Passivated | - | Ra ≤ 1.2μm |

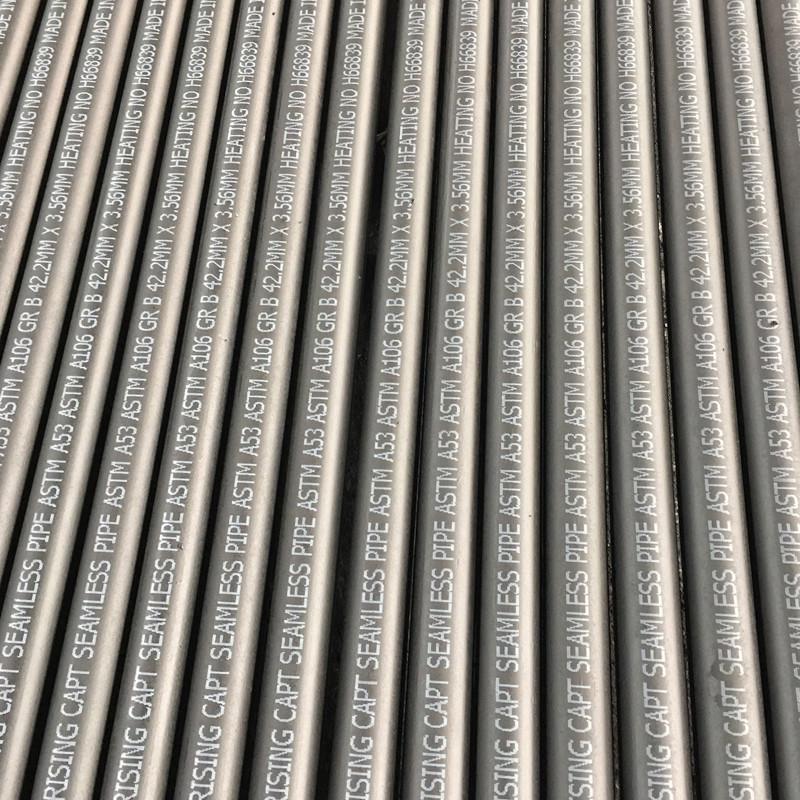

Manufacturing Process: 17 4 Seamless Tubing for Sale

17-4PH Ingot or Billet

Hollowing via Rotary Piercing or Extrusion

Seamless Pipe Reduction to Target Size

Sizing, Facing, ID/OD Machining

Solution Annealing & Age-Hardening

Eddy Current, Ultrasonic, PMI, Hydro-Test

Pickling, Passivating, Marking

Protective End Caps, Export Cases

- Hot Piercing & Rolling (Process animation)

- CNC Machining for Accurate Dimension Control

- ISO 9001 Quality System, ANSI/API Compliance, 100% traceability via 3.1 MTC.

Material & Performance—Why Choose 17 4 Seamless Tubing for Sale?

- Precipitation hardening for outstanding strength: Mechanically outperforms conventional 304/316 in high-pressure, cyclical load conditions.

- Exceptional corrosion resistance: Laboratory pitting resistance equivalent to Duplex/Super Duplex grades.

- Wide temperature operability: Maintains mechanical properties from cryogenic -50°C to 600°C (API data).

- Extended lifecycle: Up to 130% longer in severe/CO2-H2S service than ferritic alternatives (per API industry reports).

- Proven weldability, machinability, and easy forming for custom requirements.

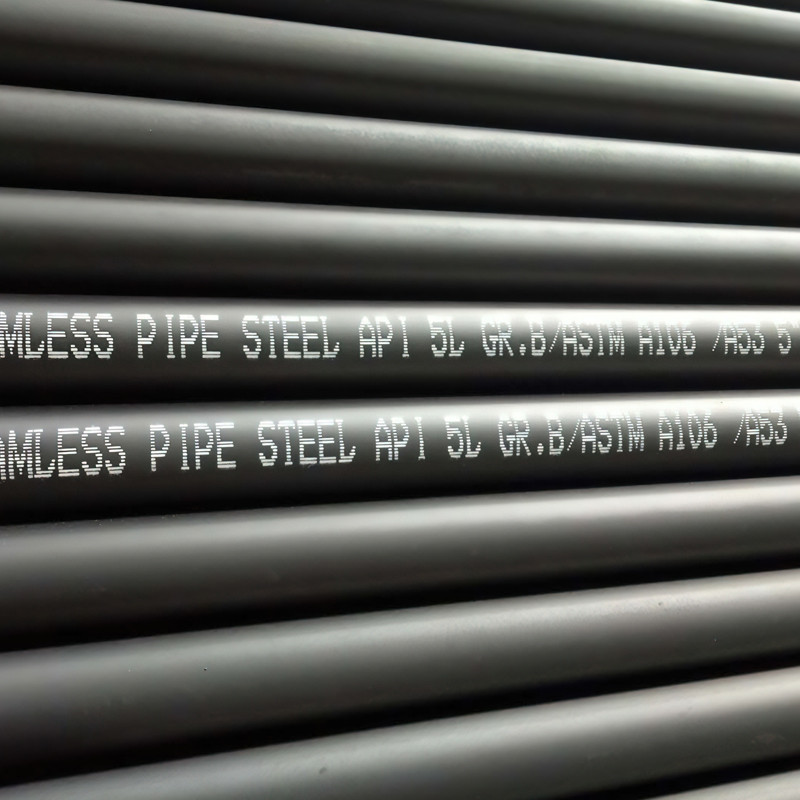

Product Benchmarking: API 5L PSL1 PSL2 Gr.B X42 X52 X60 Seamless Steel Pipe Line

Application Scenarios: 17 4 Seamless Tubing for Sale in Modern Industries

- Oil & Gas Pipelines (upstream to downstream, especially sour gas fields)

- Petrochemical process lines (exposed to aggressive chemicals)

- Water desalination & transmission (anti-corrosion, high-pressure)

- Power generation (steam/high-temperature superheater tubes)

- Automotive exhaust, mechanical drive shafts, and hydraulic cylinder liners

- Offshore engineering, drilling platforms, subsea manifolds (EN 10216 tested)

A Middle East petrochemical project replaced legacy carbon steel with 17 4 seamless tubing for sale—resulting in:

- 40% reduced maintenance events over 12 years

- 35% savings in total cost of ownership due to minimized corrosion failures

- Extended equipment uptime: 99.7% average yearly operational availability

Customization & Engineering—Your Project, Our Expertise

- Non-standard dimensions (OD, wall thickness, cut lengths, custom bends/fittings)

- Special surface finishes—mechanical/mirror, passivation, or PVDF/PTFE lined

- Dedicated pressure classes; fire-safe or sour-service certified

- Nondestructive testing options (UT, RT, PMI, hydrostatic test)

- Custom marking and packaging to project specifications

Leading Vendors: Factory Comparison Snapshot

| Vendor | Main Product Range | Certifications | Delivery Time | Customization |

|---|---|---|---|---|

| World Steel Material | API 5L PSL1/2, 17-4PH, X42–X80 | API, ISO 9001, PED, NACE | 15-30 days | Yes—Full Range |

| Vallourec | Line Pipe, OCTG, Alloy Steels | API, ISO, DNV-GL | 30-60 days | Wide |

| Tenaris | Oil & Gas, Seamless Tube | API, ISO, EN | 35-70 days | Tailored Projects |

| Nippon Steel | JIS, API 5L, CR/SS Tube | API, ISO, JIS | 45-80 days | Partial |

Lead Time, Warranty & Support

- Lead Times: Standard sizes: 15-20 days; Custom dimensions: 25-40 days depending on process complexity.

- Quality Guarantee: All pipes covered under 2-year manufacturing warranty (material/workmanship defects; terms apply).

- Customer Support: 24/7 engineering hotline & full documentation transparency (in-process photos, test certificates, shipping traceability).

FAQ—Technical FAQ

Frequently Asked Questions on 17 4 Seamless Tubing for Sale

-

Q: What is the “seamless” advantage versus welded?

A: Seamless tubes have no weld seam, delivering uniform strength, enhanced corrosion resistance, and better ductility under pressure. This is critical in oil & gas and corrosive chemical operations. -

Q: What are typical product sizes and tolerances for seamless pipeline solutions?

A: Outer Diameters from 6mm to 610mm, wall thickness from 1mm to 60mm; tight OD/W.T. tolerances up to +/- 0.5% and cut-to-length tolerances within +/- 1.5mm. -

Q: Which standards does the 17 4 seamless tubing for sale comply with?

A: Main compliance standards: API 5L (PSL1/PSL2), ASTM A312/A564, EN 10216, and certified to ISO 9001:2015, PED, NACE MR0175 for sour service applications. -

Q: How is quality controlled in the production of seamless steel pipe?

A: Multi-stage inspection: ultrasonic/Eddy current non-destructive testing, PMI (Positive Material Identification), hydrostatic testing, and surface inspection; traceability by 3.1 MTC. -

Q: Can this tubing be used in highly corrosive or high-H2S/CO2 environments?

A: Yes—its PH stainless composition, with high Cr/Ni/Mo, ensures proven pitting/crevice resistance, meeting NACE/ISO 15156 requirements for severe sour gas environments. -

Q: Are tailored ends and surface treatments available?

A: Absolutely. Options include beveled, grooved, threaded, plain ends; surface treatments like passivation, PVDF lining, or shot-peening. -

Q: What is the typical lifespan of a seamless pipeline versus welded?

A: In aggressive environments, seamless tubes (esp. 17 4 seamless tubing for sale) can last 2–3x longer due to absence of weld corrosion and superior mechanical integrity, as substantiated by lab/field case studies.

Conclusion—Why 17 4 Seamless Tubing for Sale is the Future of Seamless Pipeline Solutions

Engineered for excellence and proven in the field, 17 4 seamless tubing for sale offers unmatched reliability where safety, longevity, and efficiency are demanded. With growing compliance and stricter API/ISO/FDA norms, the future value of seamless pipe solutions only strengthens for industrial, petrochemical, and energy infrastructure.

Further reading & references:

- API Standards for Pipes & Tubes

- World Steel Association Annual Review

- Recent Developments in Seamless Pipe Market, ResearchGate

- Stainless Steel World Forum

- Frost & Sullivan: Seamless Pipes Market Forecast

Post time: Jul . 31, 2025 08:40