Searching for the ideal well casing pipe for sale? As global energy and water infrastructure demand rises, the importance of high-performance casing pipe—including casing pipe for borewell and oil/gas projects—has surged. This comprehensive guide explores the latest trends, technical parameters, application scenarios, and competitive advantages of top-tier casing pipes, with a focus on the API 5CT series (L80/N80/J55/K55 BTC).

Industry Overview: Well Casing Pipe Market Update 2024

- The global oil & gas well casing pipe market is projected to reach $10.3 billion by 2028, growing at a CAGR of 6.8% (source: Grand View Research 2024).

- Borewell casing pipe demand in emerging economies is growing due to groundwater extraction for agriculture and urban water supply.

- Key challenges include stricter ISO/API standards, rising corrosion resistance requirements, and drive toward sustainable manufacturing.

- Common sizes: 5 1/2, 7, 9 5/8, 13 3/8 inch diameters; grades: J55, N80, L80, K55, P110.

Global Well Casing Pipe Sales by Application (2023, %)

Product Spotlight: API 5CT L80/N80/J55/K55 BTC Casing and Tubing Pipe

- Standard: API 5CT / ISO 11960

- Material Grades: J55, K55, N80-1, N80-Q, L80, P110

- Diameter: 4 1/2" ~ 20" (114.3mm ~ 508mm); e.g. 5 1/2” casing pipe for sale

- Wall Thickness: 5.21–16.13mm

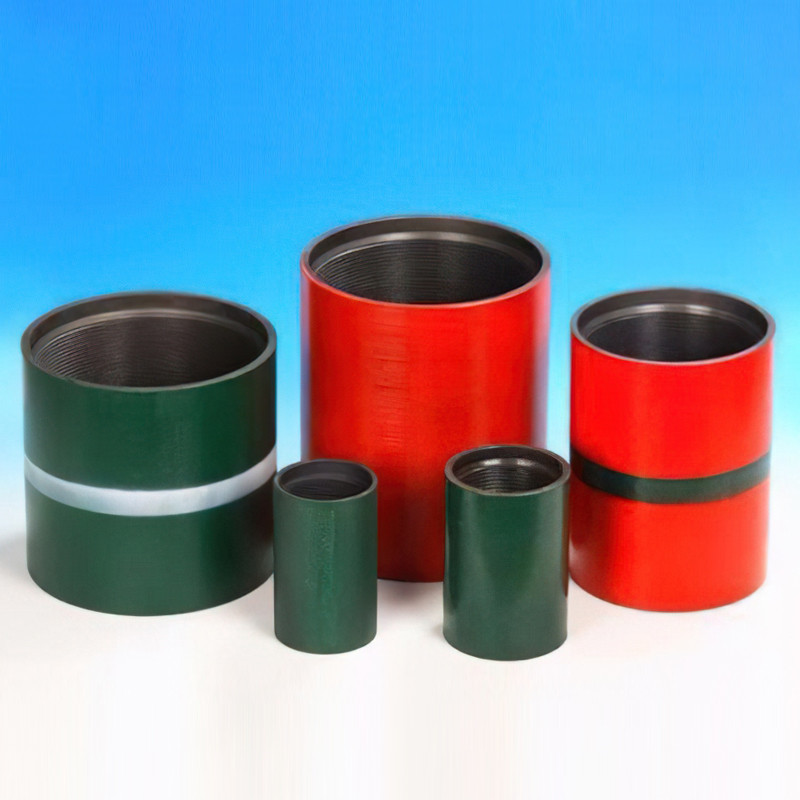

- Thread Type: BTC, LTC, STC

- Length: R1, R2, R3 (API standard pipe lengths)

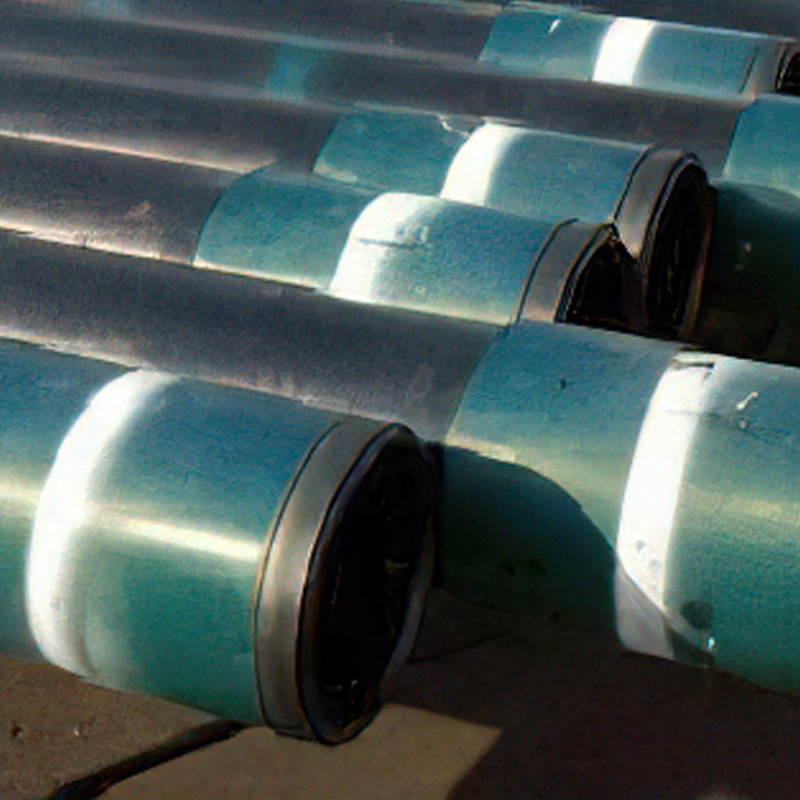

- Surface Finish: Varnished, anti-corrosion coated

| Grade | Yield Strength (MPa) | OD (inch) | Wall Thickness (mm) | Connection | Application |

|---|---|---|---|---|---|

| J55 | 379 - 552 | 5 1/2, 7, 9 5/8 | 5.21–12.7 | BTC/LTC | Water/Oil Casing |

| K55 | 379 - 552 | 5 1/2, 7, 9 5/8 | 6.10–15.88 | BTC/STC | General Borewell, Gas |

| N80 | 552 - 758 | 5 1/2, 7, 9 5/8, 13 3/8 | 5.95–16.13 | BTC/LTC | Deep Oil/Gas Wells |

| L80 | 655 - 885 | 7, 9 5/8, 13 3/8 | 6.40–15.88 | BTC/LTC | CO2/H2S Corrosive |

| P110 | 758 - 965 | 7, 9 5/8, 13 3/8 | 8.05–16.13 | BTC/LTC | Ultra-Deep Oil |

— Steel Pipes Industry Journal 2024

Manufacturing Process Flow – Well Casing Pipe

(Open hearth/BOF/EAF)

(Continuous)

(Mandrel Mill Process)

+ NDT Testing

& Final Machining

- Material Highlight: Casing pipes use high-grade carbon and alloy steel, tailored for chemical resistance and mechanical strength.

- Process: Ladle refining & continuous casting ensure steel purity.

- Forming: Hot piercing, rolling, and normalizing guarantee wall uniformity and microstructure.

- Threading: BTC (Buttress Thread), LTC, STC per ISO/API for leak-proof joints.

- Quality Control: 100% ultrasonic NDT (non-destructive), hydrostatic pressure, and hardness testing per API/ISO.

- Anti-Corrosion: Specialized phosphating or composite coatings greatly extend service life & reduce scale buildup.

Manufacturing Video

Watch the full process: API Well Casing Pipe Production (YouTube)

Competitive Analysis: Leading Well Casing Pipe for Sale vs. Peers

| Brand | Product | API/ISO Accreditation | Delivery (days) | Custom Specs | Price US$/ton | Notable Clients |

|---|---|---|---|---|---|---|

| World Steel Material | API 5CT L80/N80/J55/K55 | API, ISO 9001, ISO 14001 | 13-22 | ✔ (OD, Thread, Coating) | 1150–1390 | PetroChina, Veolia |

| Tenaris | Hydril Casing | API, ISO 9001 | 28-35 | ✔ | 1580–1700 | Shell, Aramco |

| Vallourec | VAM OCTG | API/ISO | 34-42 | ✔ | 1660–1800 | Total, ONGC |

| Nippon Steel | NSC Casing | API, JIS | 29-36 | ✔ (Size) | 1650–1800 | Petronas |

Yield Strength Comparison (MPa) – Casing Pipe Grades

Custom Solutions & Application Cases

- Custom Borewell Projects: Deep-water casing pipes with 5 1/2” and 7” diameters delivered for farmers in Rajasthan, India—reduced pump failures by 42% after switching to L80 anti-corrosion pipes (India Water Portal).

- Oilfield Development: [2024] Saudi Aramco project adopted N80Q casing for high-H2S fields, reporting 17% longer maintenance intervals (per GCC Oil Review).

- Mining Sector: Canadian diamond exploration (2023): J55 casing pipe for sale used as lining to depths of 900m, confirming API 5CT pipes' reliability under variable freezing conditions.

- Municipal Water Supply: Veolia China selected K55 for anti-leakage pressurized mains; 11-year service record with zero corrosion claims.

Casing Pipe Types Sold by Application Segment (2023, tons)

Technical Advantages of API 5CT Well Casing Pipe for Sale

- High Collapse Resistance: Advanced alloys withstand high formation and downhole pressures.

- Extended Service Life: Up to 30 years (NACE/ISO testing) in aggressive brine or H2S/CO2 environments.

- Perfect Connections: API BTC threaded joints ensure gas/liquid tightness, reducing well integrity risk.

- Custom Coatings: Epoxy/polyurethane layer options reduce both internal and external corrosion.

- End-to-End Traceability: Each pipe tracked by heat number, with mill test certificates as per ISO/API/ANSI.

- Strict Certification: All products are API, ISO, CE certified and subjected to 100% hydrostatic pressure testing.

Typical Application Scenarios

- Oil & Gas Wells: Casing installed as the permanent lining in every well — crucial for structural support and groundwater protection.

- Borewells for Agriculture: Casing pipe for borewell supports deep tube wells, preventing well collapse and contamination.

- Municipal Water Supply: Used in pressurized water mains due to leak-tight threading and high mechanical strength.

- Mining/Geotechnical: Essential as temporary or permanent casing in exploratory and resource wells.

Professional FAQ – Casing Pipe Selection, Specs & Quality

1. What material grades are available for casing pipe and what are their differences?

The main grades include J55 (standard strength), K55 (improved yield and API compliance), N80 (good strength, higher temperature tolerance), and L80 (withstand H2S/CO2, meets ISO 15156). Selection depends on well depth, formation pressure, and corrosive presence.

2. What is the meaning of "BTC" thread in API 5CT BTC Casing Pipe?

BTC stands for "Buttress Thread Coupling", an API-standard thread profile designed for strong mechanical engagement, rapid assembly, and superior gas-tightness compared to STC (Short Thread) or LTC (Long Thread).

3. What is the API 5CT regulation and why is it important?

API 5CT is the "Specification for Casing and Tubing" published by the American Petroleum Institute. It covers performance/design parameters and manufacturing tolerances for casing and tubing, ensuring safe and reliable oilfield well completion worldwide.

4. How do I select casing pipe for borewell applications?

Consider groundwater environment (pH, salinity), required diameter (usually 4"–10"), mechanical/collapse strength, and preferred threading for leak avoidance. Polyvinyl chloride (PVC) is sometimes used, but steel casing pipe offers far superior lifespan and integrity for deep borewells.

5. What is the usual delivery time for well casing pipe for sale after order?

For standard sizes (e.g. 5 1/2", 7", 9 5/8") and common grades, delivery is typically within 2–4 weeks. For custom diameters, thicknesses, or coatings, allow up to 35 days.

6. What are the main hydrostatic and mechanical tests carried out before shipment?

Each pipe undergoes non-destructive ultrasonic testing (UT), hydrostatic pressure test (per API 5CT), and mechanical tensile/yield strength test to verify batch compliance with ISO, API, NACE or localized standards.

7. What warranty and quality support do you provide?

World Steel Material offers a 12–24 month warranty against manufacturing defects. Product is traceable and accompanied by mill certificates. Technical/customer support is available 24/7 for field or installation guidance.

Order & Support Information

- Delivery Time: Stocked models ship in 2–3 weeks; custom specs up to 35 days.

- Warranty: 12–24 months (grade- and order-dependent). Full reclaimed/replacement policy per contract.

- International Certification: API, ISO 9001, ISO 14001, CE, NACE as applicable.

- Technical Support: 24/7 hotline, on-site field support by API-certified engineers, remote video QA/assistance.

- After-Sales Service: Dedicated account managers, lifetime data retention for all test records.

Post time: Jul . 30, 2025 06:20