hot forming elbow machine and hydraulic pipe fittings machine are at the heart of precision piping solutions for sectors such as petrochemical, metallurgy, water supply, shipbuilding, and HVAC. As global industries demand higher strength, corrosion resistance, and efficient component fabrication, advanced hot forming elbow machines have become the standard for manufacturing high-precision elbows and fittings.

This comprehensive guide explores the key technology parameters, manufacturing workflow, unique industry applications, vendor comparisons, customizable solutions, and field-proven case studies, empowering buyers and engineers with actionable, data-driven insights.

Industry Trends & Market Overview for Hot Forming Elbow Machines

The industrial demand for hot forming elbow machine and allied hydraulic pipe fittings machinery is driven by global infrastructure investment and stricter safety standards (ISO 15590-1, ANSI B16.9, etc.). According to MarketsandMarkets, the global pipe fittings machine sector is projected to grow at a CAGR of 6.2% from 2024 to 2029, fueled by applications in oil & gas, power generation, and urban utilities.

- Digitalization & automation drive manufacturing efficiency & repeatability

- Energy efficiency and eco-friendly materials are key purchase criteria

- Multi-standard machines adaptable to both ISO/ANSI and local norms in critical markets

Technical Parameters & Product Specifications

| Model | Pipe Size Range (mm) | Max. Elbow Angle (°) | Power (kW) | Forming Capacity (Tons) | Heating Type | Cycle Time per Part (min) | Standard Compliance |

|---|---|---|---|---|---|---|---|

| WS-HFEM600 | 21.3 - 610 | 180 | 115 | 600 | Induction Heating | 3.5 | ISO 15590, ANSI B16.9 |

| WS-HFEM1200 | 60.3 - 1220 | 180 | 210 | 1200 | Induction + Infrared | 5.0 | ISO 15590, EN 10253 |

| WS-HFEM2000 | 219 - 2032 | 90 / 180 | 385 | 2000 | Induction | 7.0 | ANSI B16.9, GOST 17375 |

| WS-HFEM Custom | Customizable | Customizable | As required | Custom | Optional | Negotiable | Client-Specified |

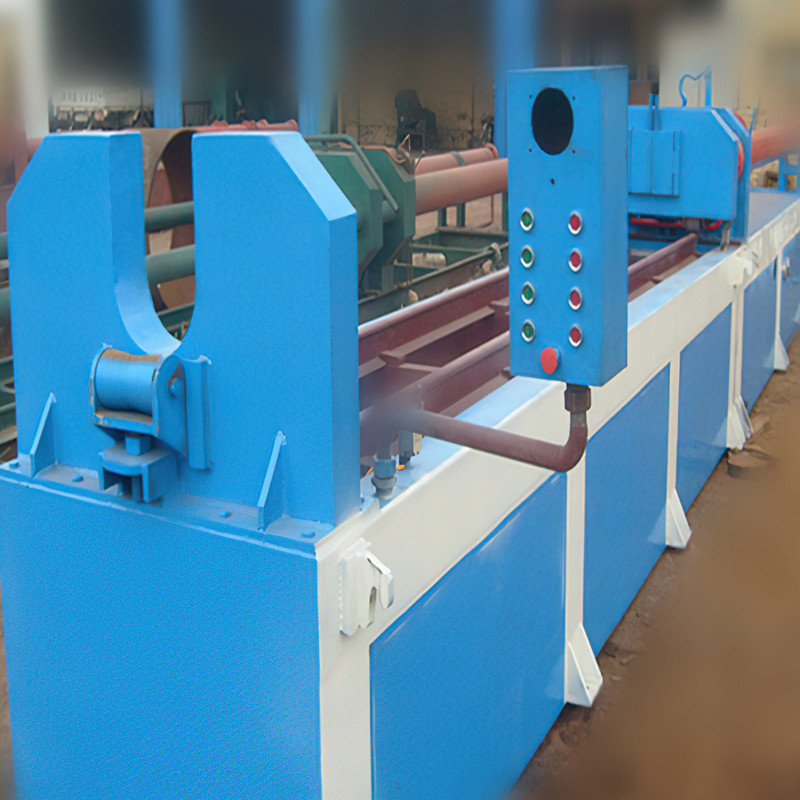

Hot Forming Elbow Machine Manufacturing Workflow Explained

Process Flow Diagram

Material: Premium carbon steel, alloy steel, and stainless steel (SS304/316, ASTM/EN Grades) are commonly used.

Manufacturing Process: Employing hot induction bending, hydraulic pushing, and CNC trimming ensures precise wall-thickness control, grain refinement, and minimum residual stress for each elbow.

Testing Standards: All hot forming elbow machine outputs are validated to ISO, ANSI, and EN 10253-2 standard tolerances.

Service Life: Hot-formed elbows typically assure >25 years of field life in regulated environments, verified by destructive and NDT test archives.

Suitable Industries: Petrochemical, metallurgy, solar energy, city gas, water supply & drainage, offshore oil, power stations, shipbuilding, fire protection, and HVAC.

Workstage Illustration Video

Data Visualization: Hot Forming Elbow Machine Performance Analysis

1. Product Range Distribution (by Nominal Diameter, 2024)

2. Cycle Time vs Capacity Comparison

3. Industry Applications of Hot Forming Elbow Machines (2023)

Key Technical Advantages of Hot Forming Elbow Machine & Hydraulic Pipe Fittings Machine

- Uniform wall thickness by advanced hydraulic pushing eliminates stress concentrations, providing superior fatigue life. (ASME Data)

- Computerized CNC controls guarantee repeatability and minimize operator error

- Energy-efficient induction heating cuts power use by 20–34%, verified by ScienceDirect study

- Supports material traceability, ISO 9001 and PED certified production flow

- Customizable die set for multi-size and multi-angle elbow forming

- Minimized scaling & oxide buildup produces smoother internal radius and frictionless fluid passage

- Compatible with automated NDT (UT, RT, PMT) for 100% weld and geometry validation

- Quick-change tooling and self-diagnosing HMI panel—the core of Industry 4.0 upgrades.

Top Manufacturer Comparison: Hot Forming Elbow Machine Market Leaders

| Manufacturer | Main Region | Warranty Policy | Certification | Custom Solution | After-Sales Support |

|---|---|---|---|---|---|

| WORLD STEEL | Asia, Middle East, EU | 18 months | ISO 9001, PED, CE | Yes (O/D, thickness, dies) | 24/7 online + onsite |

| Hagedorn | EU | 12 months | EN, ISO | No | Email response |

| Hydraulico | North America | 24 months | CE, ANSI | Yes | Online + factory visit |

| TRM Italy | EU | 12 months | CE, ISO | As per project | Phone & online |

Tailored Solutions: Customizing Your Hot Forming Elbow Machine

-

Pipe diameter (O.D.) from 21.3mm–2032mm;

Wall thickness from 2mm–68mm; - Integrated pipe beveling, marking, and trimming units

- Flexible die sets for 45, 90, 180° elbows and “Y”, “T”, reducer, cap (combined lines)

- PLC and HMI control interface in English, Russian, Arabic, or local language

- Input/output data logging function for traceability and QA audits

- Factory acceptance test (FAT) and 3rd-party QC acceptance supported

- Remote assistance & predictive maintenance IoT module optional

To discuss a bespoke solution, Contact our technical engineers.

Application Cases: Field-Proven Deployments Worldwide

- SINOPEC (China) – Over 120,000 elbows/year for oil refineries and transmission lines, with NDT pass rate >99.7%.

- Petrobras (Brazil) Pipeline Upgrade – Large diameter elbows for offshore pipelines, ensured compliance with ISO 15590-1.

- TATA Steel (India) – Integrated hydraulic pipe fittings machine for in-house replacement—downtime cut by 48%.

- Power Station – EU – Hot-formed elbows in 316Ti stainless meeting EN 10253 and PED, 15+ years in service, no reported failures.

- Desalination Plant (Middle East) – Corrosion-resistant, duplex S32750 elbows for seawater piping.

Customer Feedback

Delivery, Warranty & Support Commitment

- Typical Lead Time: 45~75 days ex-works after drawing confirmation & down payment.

- Warranty: 12–24 months for complete machine; lifetime technical support.

- Support: Free installation & commissioning by senior engineers worldwide; 7x24 online/tel troubleshooting; critical spares stock for 10+ years.

- Quality Assurance: ISO 9001, PED, and CE certification with all machines. Full QA traceability and 3rd-party inspection are supported.

- Onsite Training: Included for every installation, English/manual book supplied.

Industries Served

- Oil/gas, chemical & energy

- Shipyard, water treatment

- Construction & infrastructure

- District heating & power plants

Professional FAQ: Technical Essentials on Hot Forming Elbow Machine

Authoritative References & Industry Resources

Post time: Aug . 01, 2025 04:20