- Overview of the Flange Industry and Market Potential

- Technical Advantages and Innovation in Flange Manufacturing

- Comprehensive Comparison of Leading Flange Manufacturers

- Integration of Steel Structures and Pipe Caps with Flanges

- Customized Solutions: Meeting Diverse Industrial Requirements

- Application Cases: Real-World Success Stories

- Solutions for Sourcing the Best Flange for Sale

(flange for sale)

Overview of the Flange for Sale Market

The current global industrial landscape places significant emphasis on the supply and demand of high-quality flanges for sale. Projections by Global Market Insights estimate that the worldwide flange market, valued at USD 5.6 billion in 2023, is set to surpass USD 8.9 billion by 2028, fueled by the burgeoning construction, oil & gas, and water treatment sectors. Growth is especially strong in regions prioritizing infrastructure modernization, including North America and Asia-Pacific, where steel structure for sale and pipe cap for sale products complement flange offerings. The constantly evolving manufacturing standards and increased engineering project complexity necessitate robust, precision-machined connections, highlighting the pivotal role of flanges.

Technical Advantages and Innovations in Flange Manufacturing

Technological innovation lies at the core of flange production, addressing challenges such as corrosion resistance, mechanical strength, and dimensional consistency. Materials like carbon steel, stainless steel, and alloy steel are meticulously selected to satisfy diverse application environments, from offshore platforms to chemical facilities. The adoption of hot forging, precision machining, and automated QC testing ensures dimensional accuracy within spectrums as tight as ±0.1 mm. Additionally, non-destructive testing (NDT) such as ultrasonic and radiography is a standard requirement, ensuring each flange meets or exceeds international standards like ASME B16.5 and EN 1092-1.

Modern manufacturers leverage CAD-assisted design for bespoke flange geometry, and advances in surface treatments—including hot-dipped galvanizing and epoxy coatings—enhance service life by up to 40% compared to untreated alternatives. Meanwhile, the introduction of integrated automatic welding robots raises production capacity and stability, reducing lead times for urgent infrastructure projects. These innovations not only elevate the reliability of flanges but also drive down total cost of ownership for industrial consumers.

Comprehensive Manufacturer Comparison: Data-Driven Insights

Selecting a reliable manufacturer is crucial for seamless project execution. Key manufacturers vary significantly in terms of production scale, material quality, and after-sales support. The following table outlines the comparative strengths of industry leaders based on rigorous market research:

| Manufacturer | Annual Output (Tons) | Certifications | Lead Time (Days) | Technical Support | Product Range |

|---|---|---|---|---|---|

| GlobalForge Ltd. | 55,000 | ASME, ISO 9001, PED | 18-28 | 24/7 Engineering Consulting | Flanges, Steel Structures, Pipe Caps |

| SteelMaster Inc. | 40,000 | EN 1092-1, API, ISO 14001 | 22-35 | In-house R&D Team | Flanges, Pipe Fittings, Pipe Caps |

| PrimeSteel Works | 27,000 | ISO 9001, ASME | 30-45 | On-request Technical Reports | Custom Flanges, Sheet Metal, Pipe Caps |

| FlowConnect | 32,000 | ASME, API | 25-38 | Dedicated Project Managers | Flanges, Steel Structures for Pipelines |

The comparative data underscores the importance of balancing speed, certification, and product breadth when choosing suppliers; GlobalForge Ltd. distinguishes itself through high throughput and comprehensive product lines.

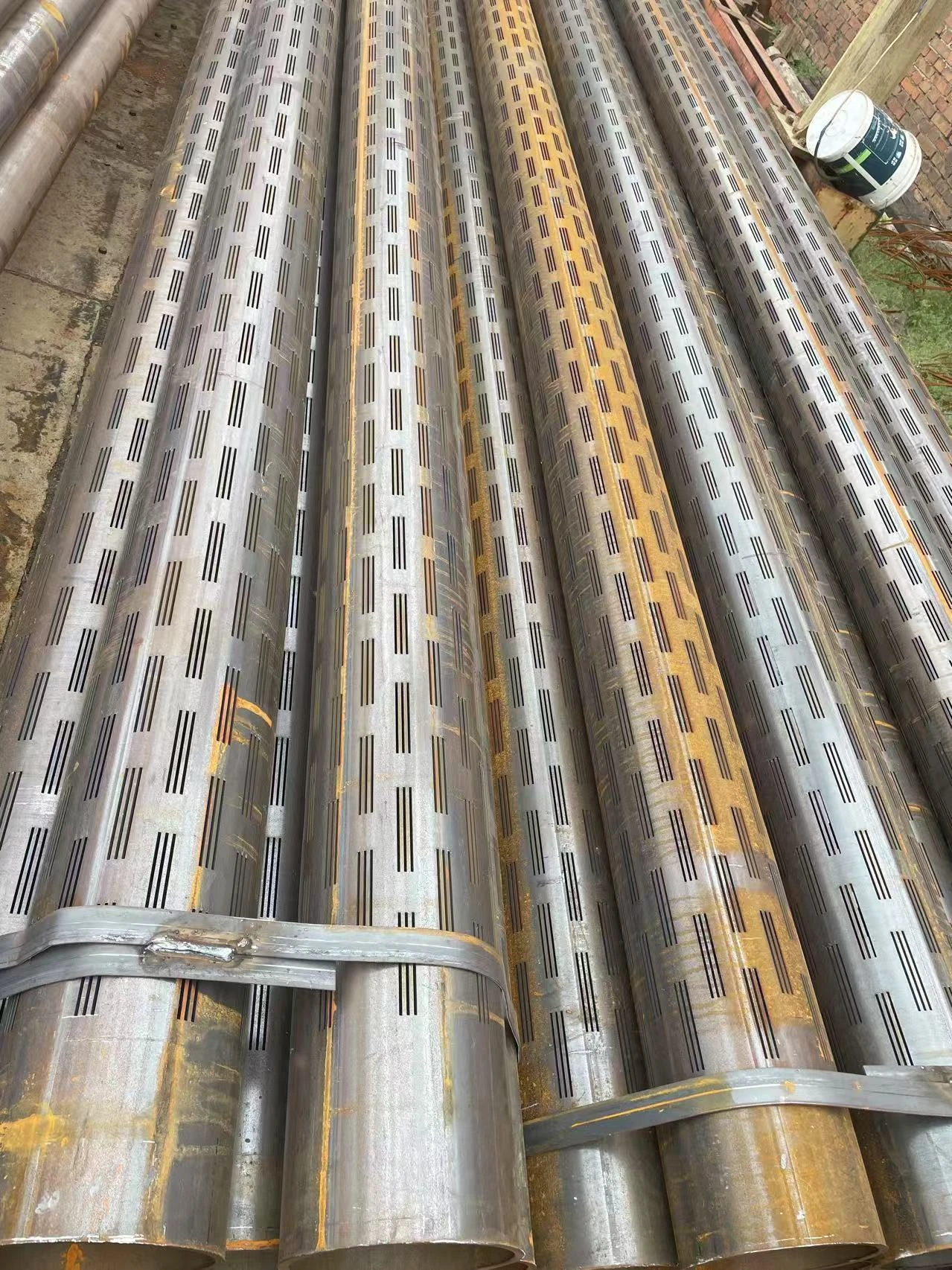

Integration of Steel Structures and Pipe Caps with Flanges

Industrial assembly projects increasingly require the seamless integration of flanges, steel structures for sale, and advanced pipe cap designs. Modular steel structures, now constituting over 60% of new power and petrochemical plants, rely on precision flanges for joint stability and leak-proof performance. Sophisticated closed-die forging processes in flange manufacturing facilitate the effective coupling of large-diameter pipes and custom steel panels, reducing structural fatigue by up to 28% over traditional joining methods.

Meanwhile, pipe caps—critical for system isolation and maintenance—are frequently manufactured to conform alongside flanges, ensuring material and finish compatibility. The rise of hybrid assemblies has encouraged suppliers to provide comprehensive packages combining flanges, steel structure elements, and matching pipe caps, streamlining procurement and expediting on-site installation. This holistic supply methodology introduces time efficiencies while minimizing potential sources of mechanical mismatch or corrosion over the equipment lifecycle.

Customized Solutions: Addressing Unique Industrial Needs

Industries such as oil & gas, chemical processing, and renewable energy require non-standard solutions that off-the-shelf products cannot fulfill. Customized flanges—ranging from unusual pressure ratings (up to Class 2500) to unique geometries like lap joint and spectacle blind flanges—are increasingly common. Buyers can specify materials such as duplex stainless steel, nickel alloys, or cladded carbon steel to address demanding operating environments involving high salinity, acidic conditions, or extreme temperatures.

Modern manufacturers offer comprehensive custom engineering services, from digital modeling to rapid prototyping and batch production. CAD/CAM systems enable exacting conformity to project blueprints, while ERP-integrated order tracking provides transparency across the production cycle. Custom pipe caps and tailored steel structure elements are delivered assembled or in module form for fast track construction. Typically, custom items represent nearly 32% of all flange orders in advanced economies, highlighting the growing reliance on tailored engineering.

Application Cases: Real-World Success Stories

Consider the recent successful deployment of advanced flanges and steel structure solutions in several high-impact projects:

- Offshore Oil Platform – North Sea: Utilization of super duplex flanges and corrosion-resistant pipe caps enabled uninterrupted operation in a highly saline environment. System reliability increased by 37% compared to platforms using conventional components.

- Thermal Power Plant – India: Integration of modular steel structures and high-pressure flanges contributed to a 22% reduction in construction time and maximized pipeline efficiency.

- Municipal Water Treatment Facility – Germany: Tailored flanges and matching pipe caps ensured complete system integrity, supporting continuous operation with no pipeline failures over a 5-year review period.

- Petrochemical Expansion Project – Texas: Adoption of forged carbon steel flanges with advanced non-destructive testing decreased scheduled maintenance shutdowns by 18%.

These cases underline the critical link between precisionmanufactured flanges and long-term operational success. The combination of flange for sale

offerings with complementary steel and pipe cap solutions delivers measurable performance gains for industrial end users.

Solutions for Sourcing the Best Flange for Sale

Identifying and securing the right flange for sale is central to ensuring reliability across high-stakes projects. Buyers should prioritize partners who demonstrate a consistent track record in quality control, technical innovation, and post-sale support. Third-party certifications such as ASME, ISO 9001, and PED offer valuable assurance regarding product reliability and compliance.

Developing strong relationships with suppliers capable of providing integrated packages—including steel structures for sale and tailored pipe cap for sale options—streamlines logistics and boosts project predictability. In today’s performance-driven environment, investing in flange solutions engineered for durability and fit-for-purpose application pays significant dividends, driving both safety and cost efficiency for the full project lifecycle.

(flange for sale)

FAQS on flange for sale

Q: What types of flange for sale are available?

A: We offer a wide variety of flanges for sale, including slip-on, weld neck, blind, and threaded types. All flanges are manufactured according to international standards to ensure quality. Contact us for specific sizes and materials.Q: Are there customized steel structure for sale options?

A: Yes, we provide customized steel structure for sale tailored to your project requirements. You can specify size, shape, and material. Reach out to discuss your exact needs.Q: Do you offer pipe cap for sale in different materials?

A: Absolutely, our pipe cap for sale are available in carbon steel, stainless steel, and other alloy materials. Various sizes and coating options are also provided. Please send us your requirements for a quote.Q: Can I get discounts on bulk flange for sale orders?

A: Yes, we offer competitive discounts for bulk orders of flange for sale. The more you buy, the better the price. Contact our sales team for details.Q: Are your steel structure for sale products certified?

A: All our steel structure for sale products come with relevant quality and safety certifications. This ensures they meet global standards for construction and industrial use. Certificates can be provided upon request.Post time: Jul . 07, 2025 06:11