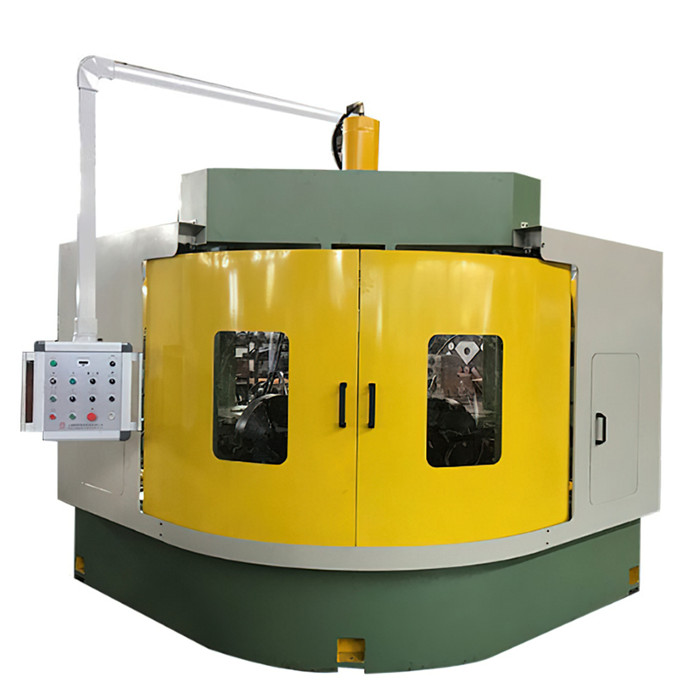

Hydraulic Pipe Fittings Machine buyers tell me the same thing every quarter: end-prep accuracy is where projects are won or lost. That’s exactly why the Q1245 Beveling Machine from Beijing (Rm 1103, Shangpintaihu Bld 3#, Tongzhou District) has been getting attention in oil & gas yards, shipyards, and fab shops that can’t afford rework. I’ve spent time with teams running it on carbon steel and duplex—real-world cycles, not showroom demos—and the takeaway is simple: consistent bevels, fewer rejects.

What it is and why it matters

Q1245 is a hydraulic-driven beveling unit used for pipe ends and fitting ends—think elbows, tees, reducers—where weld prep geometry must match spec every time. In a market leaning hard into automated fit-up and NDE-friendly joints, a Hydraulic Pipe Fittings Machine that holds bevel angle and land width without babysitting is, frankly, a quiet competitive edge.

Industry trends (quick take)

- Shift to cold-cut beveling for safety and HAZ control.

- Documentation-first QA with traceable bevel data (Ra, angle, L.O.C.).

- Modular tooling to switch from V to U or compound bevels without long downtime.

Technical snapshot (Q1245)

| Model | Q1245 Beveling Machine |

| Pipe OD Range | ≈ 25–323 mm (1"–12.75"); optional kits up to 18" |

| Bevel Types | V, U, J, compound; per ASME B16.25 |

| Max Wall Thickness | up to ≈ 20 mm (material-dependent) |

| Drive | Hydraulic, closed-loop feed; variable speed |

| Surface Finish | Ra ≤ 3.2 μm (typical); ≤ 1.6 μm with finishing pass, ISO 4287 |

| Angle Accuracy | ±0.5°; land width repeatability ≤ 0.2 mm |

| Service Life | 5–8 years in typical fab shops; real-world use may vary |

Process flow (how shops run it)

- Material ID: ASTM A106/API 5L/EN 10216 pipes; fittings to ASME B16.9.

- Clamping and centering: hydraulic jaws; concentricity check ≤ 0.05 mm TIR.

- Tooling setup: carbide inserts; geometry per joint design (V/U/J).

- Beveling pass: cold cut; feed rate tuned to wall thickness and grade.

- Inspection: bevel angle gauge, surface roughness (ISO 4287), visual to ASME B16.25.

- Documentation: lot traceability; QA sign-off for B31.3/B31.1 lines.

Where it’s used

- Refineries and petrochemical piping (ASME B31.3).

- Power plants (B31.1), boiler shops, and pressure vessels.

- Shipbuilding spool shops and offshore skids.

- Water transmission (ductile/CS) with documented bevels for automated welding.

Advantages people report: faster setup than portable torch bevels, tidy chips (no grind dust), and fewer NDE flags on root pass. One maintenance chief told me their reject rate dropped “from annoying to forgettable.” To be honest, that’s the metric that matters.

Vendor comparison (field notes, ≈ values)

| Vendor/Machine | Q1245 (Beijing) | Brand X Turret Beveler | Portable Cold-Cut Unit |

| Power | Hydraulic | Electric/Servo | Pneumatic/Electric |

| OD Range | 1"–12.75" (kits to 18") | 2"–24" | 1"–12" |

| Typical Cycle (6" Sch40) | ≈ 45–70 s | ≈ 60–90 s | ≈ 90–150 s |

| Compliance | ASME B16.25, ISO 9001 shop | ASME B16.25 | Operator dependent |

Customization and QC

- Custom jaws for short-radius elbows and reducers.

- Tooling packs for exotic alloys (duplex, Inconel) with coolant options.

- Factory QA: geometry verification to ASME B16.25; roughness to ISO 4287; hardness check per ASTM E18 on contact points; machine alignment checks per ISO 230.

Case notes (two quick scenarios)

Pipeline spool shop (API 5L pipe): moved from flame bevel to Hydraulic Pipe Fittings Machine; weld repair rate reduced by ~35% over 3 months, mainly from consistent land width.

Shipyard fab line: introduced Q1245 for stainless fittings; achieved Ra ≈ 1.8 μm with a finishing pass, enabling smoother automatic root passes.

Certifications and paperwork

Typical package includes ISO 9001 shop certification, material/tooling COC, and a run-off report. If your client spec calls out B31.3 plus B16.25 prep, you’ll want those QC sheets attached to each heat/lot—most auditors expect it now.

Authoritative citations:

- ASME B16.25 – Buttwelding Ends

- ASME B31.3 – Process Piping

- API 5L – Line Pipe

- ISO 4287 – Geometrical Product Specifications (Surface texture)

- ISO 230 – Test code for machine tools

- ASTM E18 – Rockwell Hardness Testing

Post time: Oct . 22, 2025 18:25