Industry Trends and the Evolution of Pipe Fabrication

The landscape of industrial pipe fabrication is continuously evolving, driven by demands for higher precision, increased efficiency, and enhanced material integrity. Modern infrastructure projects across sectors such as petrochemicals, oil and gas, power generation, and water treatment necessitate advanced machinery capable of producing fittings that meet stringent international standards. A critical innovation in this field is the hydraulic pipe fittings machine. These sophisticated systems are pivotal for the efficient and accurate production of components like elbows, reducers, caps, and the highly specialized output of a tee forming machine.

Current industry trends highlight a significant shift towards automation and digitalization. Manufacturers are increasingly integrating IoT and AI-driven predictive maintenance into their machinery, reducing downtime and optimizing operational costs. The focus is also on energy efficiency, with newer models designed to minimize power consumption while maximizing output. Furthermore, the capacity to handle diverse materials, from various grades of stainless steel and carbon steel to high-nickel alloys, is paramount, reflecting the expanding material science requirements of modern engineering. This commitment to innovation ensures that the components produced are not only structurally sound but also resilient against extreme conditions such as high pressure, corrosive environments, and temperature fluctuations.

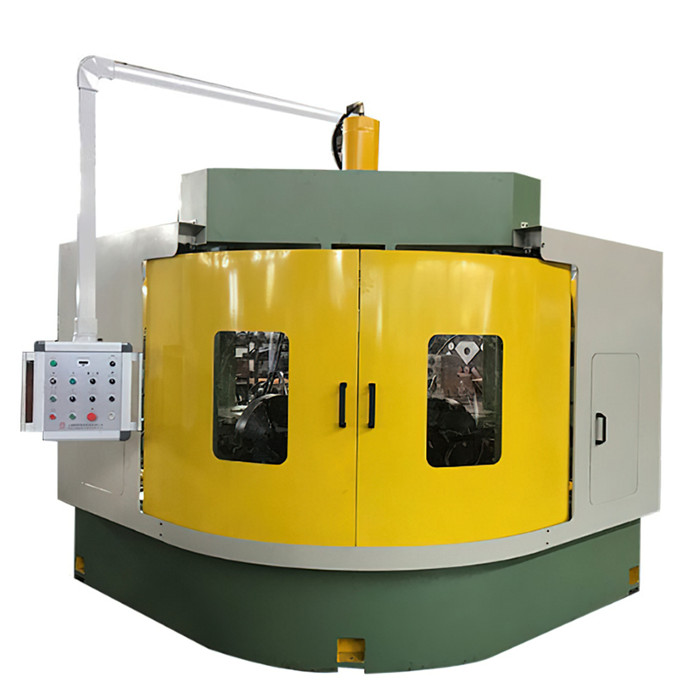

Advanced fabrication processes for pipe fittings.

Detailed Manufacturing Process of a Hydraulic Pipe Fittings Machine

The production of pipe fittings through a hydraulic pipe fittings machine involves a sophisticated multi-stage process, ensuring high-quality, durable, and precisely dimensioned products. This process integrates advanced engineering with rigorous quality control.

Process Flow Overview:

- 1. Material Selection and Preparation: High-grade raw materials, primarily seamless pipes, are selected based on end-use application. Common materials include carbon steel (ASTM A106, A53), stainless steel (ASTM A312, A213), and various alloy steels. These pipes undergo initial cutting to precise lengths using automated saws.

- 2. Forming Process (Hot or Cold):

- Hot Forming: For larger diameters and thicker walls, pipes are heated in induction furnaces to specific temperatures (typically 900-1100°C for steel) to enhance malleability. The heated pipe is then placed into the hydraulic machine, which uses powerful dies and mandrels to form the desired shape (e.g., elbow, reducer, tee). This method reduces internal stresses and ensures structural integrity.

- Cold Forming: For smaller diameters and thinner walls, pipes can be formed at ambient temperatures using precise hydraulic force. This process often offers better surface finish and tighter tolerances but requires higher material ductility.

- 3. Sizing and Calibration: After initial forming, fittings may undergo further sizing operations to achieve exact dimensions and wall thicknesses as per specifications. This step ensures uniformity and adherence to geometric tolerances.

- 4. Machining and Beveling: CNC machining centers are used for precision finishing, including boring, facing, and especially beveling the ends. Beveling is crucial for optimal welding preparation, ensuring strong, defect-free joints in final assembly. Our Q1245 Beveling Machine, for instance, specializes in creating precise bevels for various pipe sizes.

- 5. Heat Treatment: Post-forming, fittings often undergo specific heat treatments such as annealing, normalizing, or tempering. This step relieves residual stresses, refines grain structure, and optimizes mechanical properties like hardness and toughness, extending the service life of the components.

- 6. Surface Treatment: Depending on application, fittings may receive surface treatments like shot blasting, pickling, passivation, or protective coatings (e.g., epoxy, zinc primer) to enhance corrosion resistance and aesthetic appeal.

- 7. Non-Destructive Testing (NDT) & Quality Control: Each fitting undergoes stringent testing. This includes dimensional checks, visual inspection, radiographic testing (RT), ultrasonic testing (UT), magnetic particle inspection (MPI), and dye penetrant inspection (DPI) to detect any internal or surface flaws. Material composition is verified via Positive Material Identification (PMI).

- 8. Marking and Packaging: Conforming fittings are marked with material grade, size, schedule, and manufacturer's logo. They are then carefully packaged to prevent damage during transit.

Testing standards rigorously followed include ISO 9001, ASTM (e.g., ASTM A234 for carbon and alloy steel fittings, ASTM A403 for wrought stainless steel fittings), ANSI B16.9, ASME B16.9 (for factory-made wrought butt-welding fittings), and EN standards. These standards ensure product reliability and interoperability across global supply chains. The typical service life of such fittings, when manufactured to these specifications, often exceeds 20-30 years, even in harsh operational environments.

Target industries benefiting from these advanced manufacturing processes include petrochemicals (high-pressure, high-temperature lines), metallurgy (abrasion-resistant applications), and water supply & drainage (corrosion-resistant and leak-proof systems). Advantages in these scenarios include significant energy savings due to optimized flow dynamics, superior corrosion resistance through advanced material selection and surface treatments, and enhanced operational safety due to reduced risk of failure.

Technical Specifications of Modern Pipe Fittings Machines

A modern hydraulic pipe fittings machine is engineered for precision, robustness, and adaptability. Understanding its technical parameters is crucial for B2B decision-makers assessing their investment. Below are typical specifications for high-performance models, including those designed for specialized tasks such as tee forming.

Typical Product Specifications Table: Hydraulic Pipe Fittings Machine (e.g., for Elbow/Reducer Forming)

| Parameter | Specification | Notes/Range |

|---|---|---|

| Forming Method | Hydraulic Extrusion/Mandrel Forming (Hot/Cold) | Suitable for various fitting types. |

| Applicable Pipe Diameter | DN15 - DN1200 (NPS ½" - 48") | Varies by model and tooling. |

| Wall Thickness Range | 2 mm - 100 mm (Sch10 - SchXXS) | Max thickness depends on material strength. |

| Forming Pressure | Up to 5000 Tons | High pressure for large diameter/thick wall forming. |

| Main Motor Power | 75 kW - 450 kW (depending on tonnage) | Energy-efficient servo-hydraulic systems available. |

| Control System | PLC (Siemens, Mitsubishi, Fanuc) with HMI Touchscreen | Intuitive operation, diagnostic capabilities. |

| Dimensional Accuracy | ISO EN 10253, ASME B16.9 compliant | Ensures precise fitting for welding and installation. |

| Safety Features | Emergency Stop, Light Curtains, Interlocks | CE certified components. |

These specifications underscore the capabilities of modern hydraulic pipe fittings machines to handle diverse project requirements. The robust hydraulic systems ensure consistent forming pressure, critical for maintaining uniform wall thickness and material integrity during deformation processes. High-precision control systems allow for repeatable operations and minimize material waste, leading to significant cost savings in high-volume production.

Precision engineering for consistent output.

Application Scenarios and Technical Advantages

The versatility and precision of a hydraulic pipe fittings machine make it indispensable across a multitude of heavy industries. Its technical advantages translate directly into operational efficiencies and enhanced safety in critical applications.

Key Application Scenarios:

- Oil & Gas Industry: Fabrication of high-pressure and high-temperature fittings for upstream (drilling, extraction), midstream (pipelines), and downstream (refining, petrochemicals) operations. Essential for conveying crude oil, natural gas, and refined products safely.

- Power Generation: Production of robust fittings for steam lines, cooling systems, and critical process piping in thermal, nuclear, and hydroelectric power plants, where reliability under extreme conditions is non-negotiable.

- Chemical Processing: Manufacturing of corrosion-resistant fittings from specialized alloys for handling aggressive chemicals and maintaining process integrity in chemical plants.

- Water Treatment & Desalination: Production of large-diameter fittings for municipal water distribution networks and desalination plants, requiring high integrity against water pressure and corrosive elements.

- Shipbuilding: Custom pipe bends and fittings for marine propulsion systems, fluid transfer, and structural components that demand high strength and fatigue resistance.

Technical Advantages:

- Unparalleled Precision and Repeatability: Advanced hydraulic controls and CNC integration ensure that each fitting meets exact dimensional tolerances, critical for consistent performance and ease of installation. This minimizes rework and waste.

- Enhanced Material Integrity: Controlled forming processes, especially hot forming, prevent excessive material thinning or localized stress concentrations, preserving the mechanical properties of the raw material throughout the fitting.

- High Production Efficiency: Automated cycles and powerful hydraulics enable rapid forming, significantly increasing throughput compared to manual or less advanced methods. This is particularly beneficial for high-volume orders of standard or custom fittings.

- Versatility in Material Handling: Capable of forming fittings from a wide range of materials, including carbon steel, stainless steel, alloy steel, and non-ferrous metals, accommodating diverse industry requirements.

- Reduced Labor Costs & Increased Safety: Automation minimizes manual intervention, reducing labor requirements and eliminating risks associated with manual forming operations. Integrated safety features (e.g., light curtains, emergency stops) ensure operator protection.

- Optimal for Specialized Fittings: Highly effective for producing complex geometries, such as those made by a tee forming machine, which require precise control over material flow and distribution.

The investment in a high-quality hydraulic pipe fittings machine thus translates into superior product quality, reduced operational costs, and the ability to meet demanding project specifications, fostering long-term reliability for critical industrial applications.

Ensuring quality and efficiency in diverse industrial applications.

Vendor Comparison and Customized Solutions

Selecting the right hydraulic pipe fittings machine vendor is a critical decision that impacts long-term operational efficiency and product quality. A thorough comparison should consider not only technical specifications but also after-sales support, customization capabilities, and industry reputation.

Vendor Comparison Table: Hydraulic Pipe Fittings Machines

| Feature/Vendor | Vendor A (Global Precision Systems) | Vendor B (Industrial Automation Corp) | Vendor C (World Steel Material Co.) |

|---|---|---|---|

| Max Tonnage | 3000 Tons | 4500 Tons | 5000 Tons |

| Pipe Diameter Range | NPS ½" - 36" | NPS 1" - 42" | NPS ½" - 48" |

| Control System | Basic PLC (Local) | Siemens S7-1500, HMI | Advanced PLC (Siemens/Mitsubishi), Remote Diagnostics, IoT-ready |

| Customization Options | Limited (Standard tooling) | Moderate (Tooling adaptation) | Extensive (Machine design, tooling, integration) |

| After-Sales Support | Standard 1-year warranty, phone support | 1-year warranty, on-site support (regional) | 2-year warranty, global on-site support, remote monitoring, dedicated account manager |

| Certifications | ISO 9001 | ISO 9001, CE | ISO 9001, CE, TUV, PED |

Customized Solutions for Unique Requirements:

Many industrial projects demand pipe fittings that fall outside standard dimensions or require specialized material handling. This is where the ability to provide customized solutions for a hydraulic pipe fittings machine becomes invaluable. World Steel Material Co. excels in collaborating with clients to develop tailor-made machinery, addressing specific challenges such as:

- Unusual Pipe Dimensions: Designing and manufacturing specialized dies and mandrels for pipes with non-standard diameters or wall thicknesses, ensuring perfect fit and form.

- Exotic Materials: Adapting machine parameters and tooling materials to handle highly specialized alloys (e.g., Duplex, Super Duplex, Inconel) that require precise temperature control and specific forming pressures to avoid material degradation.

- Integrated Production Lines: Designing machines that seamlessly integrate into existing or planned automated production lines, optimizing material flow from cutting to finishing. This includes specialized tee forming machine units integrated for continuous production.

- Specific Throughput Requirements: Scaling machine capacity and automation levels to meet precise production volume targets, whether for batch processing or high-volume continuous output.

- Specialized Fitting Geometries: Developing bespoke tooling and programming for unique fitting shapes or complex branching configurations beyond standard elbows and tees.

Our engineering team works closely with clients from conceptualization through commissioning, ensuring that every customized solution delivers optimal performance and adheres to the strictest industry standards. This bespoke approach minimizes risks and maximizes return on investment for highly specialized projects.

Application Case Studies & Customer Success

Real-world applications demonstrate the tangible benefits of investing in a high-performance hydraulic pipe fittings machine. Our experience and customer feedback consistently highlight improved efficiency, enhanced product quality, and significant cost savings.

Case Study 1: Large-Scale Oil & Gas Pipeline Project

- Challenge: A major energy company required a consistent supply of large-diameter (NPS 48", Sch 80) carbon steel elbows and reducers for a new cross-country pipeline. Previous suppliers struggled with maintaining uniform wall thickness and meeting aggressive delivery schedules.

- Solution: We supplied a custom-engineered 5000-ton hot-forming hydraulic pipe fittings machine with advanced induction heating and automated material handling. The machine was capable of forming elbows with a uniform wall thickness deviation of less than 3%.

- Results: The client achieved a 30% increase in production throughput and a 15% reduction in material waste due to fewer rejects. The consistency of the fittings significantly reduced welding time and improved overall pipeline integrity, meeting ISO 3183 standards. The project was completed ahead of schedule, attributing substantial savings to the efficiency of our machine.

Case Study 2: Municipal Water Treatment Plant Upgrade

- Challenge: A municipal utility needed a specialized tee forming machine to produce corrosion-resistant stainless steel tees (DN600, Sch 40) for a new water treatment plant. The design required specific branch outlet dimensions and smooth internal surfaces to prevent sediment build-up.

- Solution: We provided a customized hydraulic tee forming machine equipped with precision internal mandrels and a proprietary cold-forming process for stainless steel. This ensured a smooth internal finish and precise dimensional accuracy for the branch outlets.

- Results: The client reported a 99% success rate in producing defect-free tees, eliminating the need for costly post-forming internal grinding. The superior surface finish and precise geometry contributed to optimal flow characteristics and extended service life of the piping system, exceeding their initial expectations for water quality management.

These cases exemplify our commitment to delivering machines that not only meet but exceed client expectations in the most demanding industrial environments. Our expertise ensures reliable performance and a robust return on investment.

Delivering high-performance solutions for critical infrastructure.

Commitment to Trustworthiness: FAQ, Lead Time, Warranty & Support

At World Steel Material Co., we understand that a significant investment in a hydraulic pipe fittings machine demands absolute trust in the product and the supplier. Our commitment to transparency, robust support, and clear policies underscores our trustworthiness.

Frequently Asked Questions (FAQ):

- Q1: What materials can your hydraulic pipe fittings machines process?

A1: Our machines are designed to process a wide array of materials including carbon steel (e.g., A106, A53), stainless steel (e.g., 304, 316, Duplex), and various alloy steels (e.g., A335 P11, P22). Custom tooling and process parameters can be developed for exotic alloys.

- Q2: What is the typical lead time for a new machine?

A2: Standard machine models typically have a lead time of 10-14 weeks from order confirmation to shipment. For custom-designed machines or those with highly specialized tooling, lead times may extend to 16-24 weeks, depending on complexity. Specific project timelines will be detailed in your quotation.

- Q3: Do you provide installation and training services?

A3: Yes, we offer comprehensive on-site installation, commissioning, and operational training by our certified technicians globally. This ensures your team is fully proficient in operating and maintaining the equipment for optimal performance and safety.

- Q4: How does a tee forming machine differ from other pipe fitting machines?

A4: While sharing the core hydraulic technology, a tee forming machine is specifically designed with specialized dies and mandrels to create precise tee branches from a main pipe. It utilizes internal expansion methods to draw material outwards, ensuring the branch opening maintains structural integrity without thinning.

Lead Time & Fulfillment Details:

Our production facility operates with lean manufacturing principles to ensure efficient order fulfillment. We maintain a transparent communication channel throughout the production process, providing regular updates on fabrication milestones, quality control checks, and estimated shipment dates. Logistics are managed by experienced professionals to ensure timely and secure delivery to your facility worldwide. Expedited manufacturing options are available upon request for urgent projects.

Warranty Commitments:

World Steel Material Co. provides a standard two-year warranty on all new hydraulic pipe fittings machine purchases, covering manufacturing defects and major component failures under normal operating conditions. This commitment reflects our confidence in the quality and durability of our engineering. Extended warranty packages, including preventative maintenance schedules, are also available for enhanced peace of mind.

Customer Support & After-Sales Service:

Our dedication to customer satisfaction extends long after the sale. We offer comprehensive after-sales support, including:

- 24/7 Technical Assistance: A dedicated support team available via phone, email, and remote diagnostic tools to address operational queries or technical issues promptly.

- Spare Parts Availability: A global network ensures quick access to genuine spare parts, minimizing downtime. Critical components are often stocked regionally.

- Scheduled Maintenance Programs: Tailored maintenance contracts to ensure the longevity and optimal performance of your equipment.

- Software Updates: Regular firmware and software updates for control systems, enhancing machine capabilities and introducing new features.

We pride ourselves on building long-term partnerships, ensuring your investment continues to deliver exceptional value throughout its operational lifespan.

Conclusion

The modern hydraulic pipe fittings machine stands as a testament to advanced industrial engineering, offering unmatched precision, efficiency, and material integrity for critical applications across diverse sectors. From the rigorous demands of the oil and gas industry to the specialized requirements of water treatment, these machines, including the specialized tee forming machine, are instrumental in delivering high-quality, compliant pipe fittings. By understanding their detailed manufacturing processes, technical specifications, and the advantages they confer, B2B stakeholders can make informed decisions that drive operational excellence and project success. Our commitment to customized solutions, robust after-sales support, and adherence to global standards ensures that an investment with World Steel Material Co. is an investment in long-term reliability and performance.

References:

- American Society of Mechanical Engineers (ASME). ASME B16.9: Factory-Made Wrought Butt-Welding Fittings.

- International Organization for Standardization (ISO). ISO 9001: Quality Management Systems – Requirements.

- ASTM International. ASTM A234/A234M: Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High-Temperature Service.

- European Committee for Standardization (CEN). EN 10253: Butt-welding pipe fittings.

Post time: Sep . 11, 2025 11:00