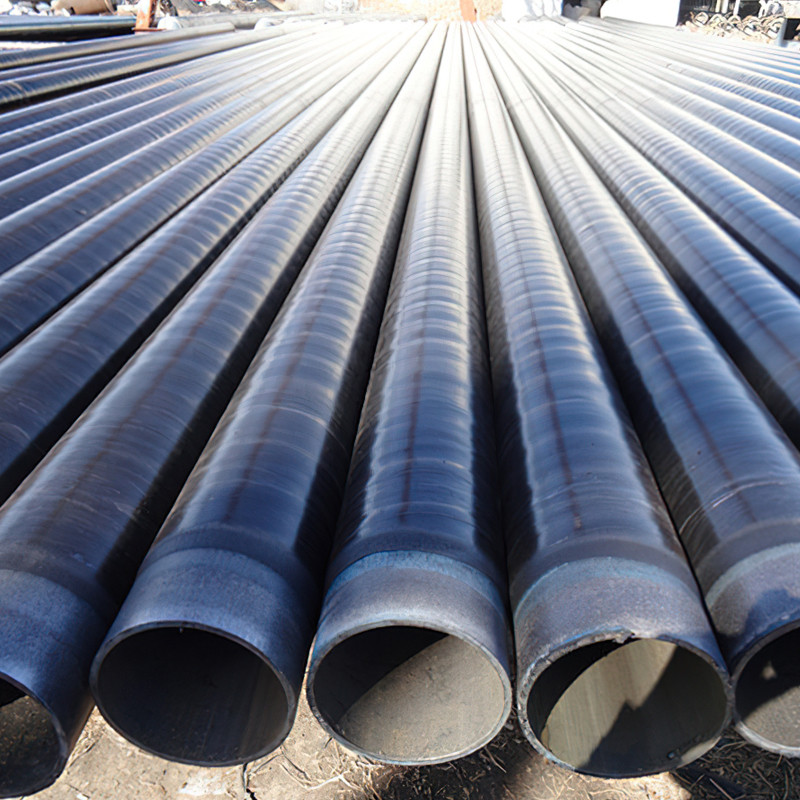

ANTI-CORROSION PIPE-3LPE/PP/FBE: field notes from the coating line

If you spend enough time around pipeline projects, you quickly learn the quiet hero isn’t the steel—it’s the coating. This is where the anti corrosion pipe story gets interesting: 3LPE/3LPP/FBE systems that keep water, gas, and chemicals in—and rust out. I’ve toured a few plants; this one in Tongzhou District, Beijing (Rm 1103, Shangpintaihu Bld 3#) stood out for consistency and straight-talking QC.

What’s trending (and why it matters)

Two macro trends: operators are pushing higher temperatures and longer design lives, and auditors are stricter about traceability. That’s nudging projects toward DIN 30670/30678 and CSA-compliant lines, plus ISO 21809 testing. Many customers say they’ll pay a bit more for coatings that pass cathodic disbondment at elevated temps—frankly, that’s smart money.

Product snapshot

Product: ANTI-CORROSION PIPE-3LPE/PP/FBE. External coating standards referenced: NF A49-710, DIN 30670, CAN CSA 21, CAN CSA 20, SY/T0413, SY/T0315 and others. Internal coating: NF A49-709, API RP 5L2, SY/T0457. Origin: Beijing, China (Tongzhou District).

| Spec item | 3LPE | 3LPP | FBE |

|---|---|---|---|

| Layer build-up | Epoxy + Adhesive + PE | Epoxy + Adhesive + PP | Fusion-bonded epoxy (single/double) |

| Typical thickness | ≈1.8–3.7 mm (DIN 30670) | ≈2.0–4.5 mm (DIN 30678) | ≈300–500 μm (CSA 20) |

| Operating temp | -40 to +80°C (project-specific) | -20 to +110°C (application-dependent) | -30 to +80°C common |

| Holiday test | 25 kV (typ.) | 25–30 kV (typ.) | 67.5 V/low voltage per CSA |

Process flow (short version)

- Abrasive blast to Sa 2.5 (ISO 8501-1), profile 50–100 μm.

- Induction preheat (≈190–240°C for FBE).

- Epoxy powder spray; for 3LPE/3LPP, add adhesive copolymer, then PE/PP topcoat via extrusion wrap.

- Quench/cure, cutback, bevel protection.

- Testing: holiday, peel strength, impact, bend, DSC, cathodic disbondment (ISO 21809/DIN 30670/CSA methods).

Service life: many assets target 30–50 years with proper CP. Real-world use may vary with soil, temp, and handling—more on that in the field notes below.

Where it’s used

Oil & gas lines (sweet/sour), potable water mains, district heating, offshore risers and field joints, mining slurries, and chemical transfer. Many EPCs pick anti corrosion pipe with 3LPP for higher process temps; water utilities often stick with FBE or 3LPE for economics.

| Vendor | Lead time | Standards coverage | Customization | Certs |

|---|---|---|---|---|

| This supplier (Beijing) | 4–8 weeks ≈ | DIN 30670/78, CSA 20/21, NF A49-709/710, SY/T | OD, thickness, cutback, colors | ISO 9001/14001, ISO 45001 |

| Vendor A (EU) | 6–10 weeks | Strong DIN/ISO focus | Broader PP high-temp options | ISO suite, CE |

| Vendor B (NA) | 3–7 weeks | CSA/AWWA heavy | Fast small-batch FBE | CSA Z245, AWWA |

Field results and customer feedback

- Midstream, Central Asia: 120 km crude line; 3LPE; peel strength ≥130 N/cm at 23°C; CD ≤8 mm radius (65°C, 1.5 V, 48 h). Contractor said handling damage dropped ~20% vs prior lot.

- Sea water intake, MEA: 3LPP on spool sections; retained impact >10 J after bend; zero holidays at 25 kV post-install—surprisingly clean report.

Internal linings to API RP 5L2 cut friction factor enough to shave pump energy—small but noticeable on OPEX. To be honest, the shipping crates were a bit overkill, but hey, fewer edge chips.

Customization

Options include OD 1/2"–80", coating thickness classes, extended cutbacks, custom colors, high-temp PP grades, dual-layer FBE, and internal epoxy per NF A49-709. If your spec calls for trenchless HDD, ask for enhanced impact class and tougher adhesive—experience says it’s worth it.

Compliance and assurance

Certifications: ISO 9001/14001, ISO 45001; base pipe per API 5L. Tests witnessed against ISO 21809, DIN 30670/30678, CSA (CAN CSA 21/20), SY/T0413/0315/0457, AWWA C213 for FBE where specified. Batch reports include DSC, gel time, adhesion/peel, impact, bend, holiday logs.

For procurement: specify standard edition, soil resistivity, design temp, and CP philosophy. That aligns the anti corrosion pipe stack-up with your risk model.

Citations

Post time: Oct . 13, 2025 09:15