Insider Notes on the Hot-Forming Line Everyone’s Asking About

If you’re looking at capacity boosts for elbows in carbon steel or alloys, the Hot Forming Elbow Machine has probably crossed your desk. I’ve been on a few shop floors this quarter, and—surprisingly—the mid-frequency induction models are the ones operators keep praising for reliability over sheer headline speed. To be honest, throughput is only half the story; repeatability and wall thinning control are what save you rework.

Why this matters now

Industry trend check: mid-frequency (MF) induction forming is edging out flame-based setups in new lines due to tighter energy control, lower scale, and cleaner bends for thick-wall energy pipes. Many customers say safety audits are smoother, and power draw is predictable—helpful when utilities spike.

Key specs at a glance

| Item | Spec (≈ / around means real-world use may vary) |

|---|---|

| Machine type | Median Frequency Induction Heating Hot Forming Elbow Machine |

| Condition | New; pipe production line |

| Materials | Carbon steel, stainless, alloy steel (ASTM A234/A403 families) |

| Voltage / Power | 380 V / 55 kW |

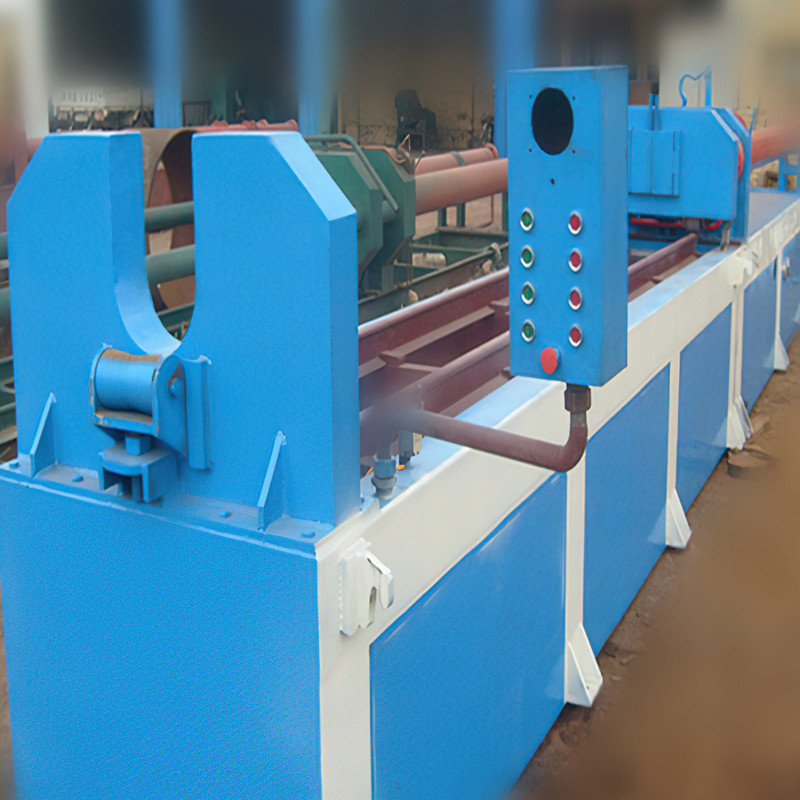

| Dimensions | ≈ 5800 × 700 × 900 mm |

| Weight | ≈ 2.5 tons |

| Typical elbow range | DN25–DN600 (R=1D/1.5D/2.5D, app-dependent) |

| Origin | Rm 1103, Shangpintaihu Bld 3#, Tongzhou District, Beijing |

Process flow (shop-floor reality)

- Cut pipe blanks → bevel/ID/OD prep

- Induction heating (MF) to forming temp (≈ 900–1000°C for CS)

- Push-bend on die; real-time temp + thrust feedback

- Calibrating/expanding → air/water quench or normalize as spec

- Heat treatment: normalize or solution treat (SS)

- NDT: UT/MT; dimensional check to ASME B16.9; hardness ≤ HB 197 (typical CS)

- Hydrotest (as required), PMI for alloy traceability

Typical test data we’ve seen: wall thinning ≤ 12.5%, ovality ≤ 2%, surface decarb minimal; service life around 20–30 years in oil & gas with proper coating and corrosion allowance.

Applications and advantages

Energy supply pipe spools, refinery revamps, district heating, slurry lines, and power plants. Advantages? Tight radius control, smoother ID flow, lower scale, and—actually—friendlier operator ergonomics than older flame rigs.

Vendor snapshot (what buyers compare)

| Vendor | Heating | Power (≈) | Control | Certs | Notes |

|---|---|---|---|---|---|

| World-Steelmaterial | MF induction | 55 kW | PLC + temp/thrust feedback | ISO 9001, CE (model-dependent) | Balanced price/performance; good spares |

| Vendor A (EU) | HF induction | 60–75 kW | PLC/SCADA | CE, ISO 14001 | Premium pricing; strong analytics |

| Vendor B (Local OEM) | Gas/flame | N/A | Basic PLC | Factory QA | Lower capex; higher scale/variance |

Customization and service

Options include coil sets for DN shifts, expanded dies, automated lube, and recipe libraries for CS vs. SS. After-sales? Around 48–72 h remote response, on-site commissioning, and operator training. It seems that real-world uptime improves when you stock spare coils and thermocouples.

Mini case study

A district heating fab shop switched to this Hot Forming Elbow Machine for DN200–DN400 elbows, R=1.5D. Result: scrap dropped by ≈18%, cycle time per elbow from 9.5 min to 7.8 min. Tests: UT 100% per ASME B16.9 tolerances; hydro at 1.5× design pressure; hardness 165–185 HB. Customer feedback? “Less soot, cleaner bends, fewer reworks.”

Standards and compliance

- Fittings geometry: ASME B16.9; EN 10253 (where specified)

- Materials: ASTM A234 (CS), ASTM A403 (SS)

- Piping code context: ASME B31.3/B31.1 (owner spec governs)

- Induction equipment safety: IEC 60519

- Quality systems: ISO 9001

References

- ASME B16.9 – Factory-Made Wrought Buttwelding Fittings.

- ASTM A234/A234M – Piping Fittings of Wrought Carbon Steel and Alloy Steel.

- ASTM A403/A403M – Wrought Austenitic Stainless Steel Piping Fittings.

- IEC 60519 – Safety in electroheating installations.

- ISO 9001 – Quality Management Systems Requirements.

Post time: Oct . 28, 2025 17:35