Optimizing Downhole Integrity: A Comprehensive Guide to Well Casing Pipe for Sale

In the demanding world of oil and gas exploration, geothermal energy, and water well construction, the integrity of a wellbore is paramount. The foundation of this integrity relies heavily on high-quality casing pipes. When considering well casing pipe for sale, discerning buyers seek not just a product, but a robust, reliable solution designed to withstand extreme downhole pressures, corrosive environments, and dynamic operational stresses. This guide delves into the critical aspects of casing pipe, covering technical specifications, manufacturing excellence, application diversity, and the strategic advantages offered by premium suppliers.

Our focus is on API 5CT certified casing and tubing pipe, specifically grades such as J55, K55, N80, and L80, often featuring Buttress Thread Coupling (BTC) connections. These materials are engineered to meet the stringent requirements of various drilling and completion operations, ensuring a secure conduit for production fluids and gases, while protecting surrounding formations from contamination.

Current Industry Trends in Casing Pipe Procurement

The global energy landscape is constantly evolving, driving new demands and innovations in the well construction sector. Key trends impacting the market for well casing pipe for sale include:

- Increased Demand for High-Strength Alloys: As drilling extends into deeper, more geologically challenging reservoirs, there's a growing need for casing pipes made from higher-strength, corrosion-resistant materials (e.g., L80, N80, P110, Q125) capable of handling higher pressures and temperatures, and resisting H₂S and CO₂ induced corrosion.

- Emphasis on Environmental Compliance and Safety: Stricter environmental regulations and an unwavering focus on operational safety are pushing for defect-free pipes, superior connection integrity, and advanced non-destructive testing (NDT) methodologies to prevent leaks and blowouts.

- Digitalization and Supply Chain Optimization: The integration of digital tools for inventory management, predictive maintenance, and real-time tracking is streamlining the procurement process, ensuring timely delivery and reducing operational costs for casing pipe.

- Customization and Specialized Solutions: Standard casing sizes remain prevalent, but there's a rising demand for tailored solutions, including specific wall thicknesses, thread types, and internal/external coatings to address unique wellbore conditions and project requirements. The search for a specific 5 1/2 casing pipe for sale or other precise dimensions reflects this trend.

- Sustainability in Manufacturing: Manufacturers are increasingly adopting eco-friendly practices, including energy-efficient production methods and responsible sourcing of raw materials, aligning with global sustainability goals.

These trends underscore the importance of partnering with suppliers who not only meet current technical standards but also innovate to address future industry challenges.

Precision Engineering: The Manufacturing Process of Well Casing Pipe

The production of high-grade well casing pipe for sale is a meticulously controlled multi-stage process, designed to ensure superior performance and longevity in the most demanding environments. This section outlines the typical manufacturing flow, emphasizing material selection, advanced processing techniques, and stringent quality control.

1. Raw Material Selection and Preparation

The journey begins with selecting high-quality steel billets or seamless tubes. For API 5CT grades like J55, K55, N80, and L80, specific chemical compositions are crucial. Materials typically consist of carbon steel alloys with controlled additions of manganese, silicon, chromium, and molybdenum to achieve desired mechanical properties, corrosion resistance, and hardenability. All raw materials undergo rigorous chemical analysis and mechanical testing to confirm compliance with API 5CT specifications and internal quality standards.

2. Pipe Forming (Seamless Manufacturing)

For seamless casing pipe, the process typically involves:

- Piercing: A solid steel billet is heated in a rotary furnace to forging temperature (e.g., 1200°C) and then pierced by a rotary piercer to form a hollow shell.

- Elongation & Rolling: The hollow shell is then further elongated and rolled through multiple stands to achieve the specified outer diameter (OD) and wall thickness. This process enhances the material's grain structure and mechanical properties.

- Sizing: The pipe is then passed through a sizing mill to achieve precise final dimensions.

Visual Representation of Seamless Pipe Manufacturing (Simplified)

Figure 1: Illustration of seamless pipe manufacturing stages for casing pipe for sale.

3. Heat Treatment

Heat treatment is a critical step to achieve the specified mechanical properties (yield strength, tensile strength, hardness) for each API grade. This typically involves:

- Quenching: Heating the pipe to a specific temperature (e.g., austenitizing temperature for N80/L80) followed by rapid cooling in water or polymer quenchants. This hardens the steel.

- Tempering: Reheating the quenched pipe to a lower temperature and then slowly cooling it. Tempering reduces brittleness and improves ductility and toughness while maintaining high strength.

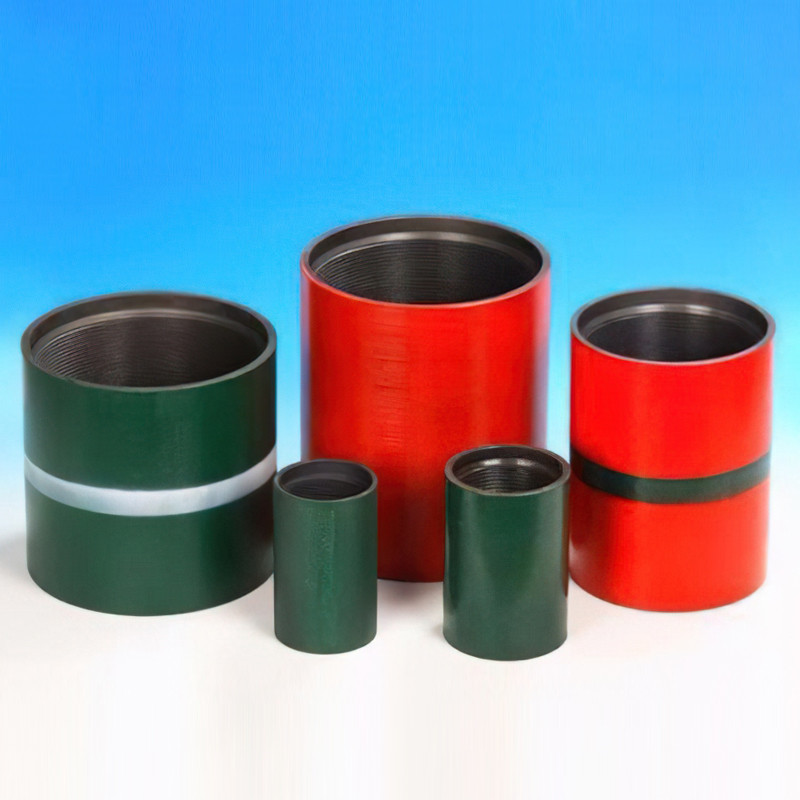

4. Threading and Finishing

The ends of the pipe are precision-machined to create the required thread profiles, such as Buttress Thread Coupling (BTC). This CNC machining process ensures high dimensional accuracy and superior connection strength, critical for sealing integrity and load-bearing capacity in downhole applications. Thread protectors are then applied to prevent damage during transport and handling.

Figure 2: Precision threading for secure connections of casing pipe for borewell.

5. Non-Destructive Testing (NDT) and Quality Control

Every length of casing pipe undergoes a comprehensive suite of tests to ensure adherence to API 5CT, ISO, and other relevant standards (e.g., ANSI, ASTM). This includes:

- Hydrostatic Testing: Pressurizing the pipe with water to confirm leak integrity and structural soundness.

- Electromagnetic Inspection (EMI): Detecting longitudinal and transverse defects on the pipe body.

- Ultrasonic Testing (UT): Identifying internal and external flaws, especially critical for high-strength grades.

- Magnetic Particle Inspection (MPI): Locating surface and near-surface discontinuities.

- Drift Testing: Ensuring internal diameter meets specifications for subsequent tooling passage.

- Dimensional Checks: Verifying OD, wall thickness, length, and straightness.

- Mechanical Property Tests: Tensile strength, yield strength, elongation, and hardness tests on samples.

This rigorous testing regime guarantees the reliability and safety of each API 5CT L80/N80/J55/K55 BTC Casing and Tubing Pipe.

6. Coating and Packaging

After final inspection, pipes may receive protective coatings (e.g., varnish, clear lacquer, or specialized corrosion-inhibiting coatings) to prevent rust during storage and transportation. Each pipe is stenciled with relevant information (grade, size, weight, heat number) and bundled securely for shipment.

Service Life & Target Industries: With proper installation and maintenance, API 5CT casing pipes offer a service life of 20-30+ years, even in challenging environments. Target industries include:

- Petrochemical: Oil & gas exploration, production, and enhanced recovery wells.

- Metallurgy: Specialized applications in mining and mineral extraction.

- Water Supply & Drainage: Deep water wells, municipal and industrial water systems.

- Geothermal Energy: High-temperature, high-pressure geothermal well completions.

Demonstrated Advantages: Our manufacturing process focuses on delivering pipes with significant advantages:

- Corrosion Resistance: Specially selected alloys and optional coatings significantly extend service life in corrosive downhole conditions.

- Energy Saving (Operational Efficiency): Precisely manufactured pipes reduce friction during installation and allow for smoother fluid flow, contributing to operational efficiency and energy savings over the well's lifespan.

- High Load-Bearing Capacity: Robust design and material integrity ensure the pipe can withstand extreme axial, radial, and torsional loads.

Technical Specifications: API 5CT Casing Pipe for Sale

Understanding the technical parameters is crucial when selecting the right well casing pipe for sale for your project. Our API 5CT L80/N80/J55/K55 BTC Casing and Tubing Pipe adheres to the highest industry standards, ensuring peak performance. Below are key specifications for common grades and sizes.

API 5CT Casing Pipe Grades and Mechanical Properties

| API Grade | Tensile Strength (min) | Yield Strength (min) | Hardness (max HRc) | Application Notes |

|---|---|---|---|---|

| J55 | 75,000 psi (517 MPa) | 55,000 psi (379 MPa) | N/A | General purpose, shallow to medium depth wells, moderate pressure. |

| K55 | 95,000 psi (655 MPa) | 55,000 psi (379 MPa) | N/A | Higher tensile strength than J55, similar yield. Deeper applications. |

| N80 | 95,000 psi (655 MPa) | 80,000 psi (552 MPa) | N/A | Intermediate strength for medium depth, moderate pressure, and temperature. |

| L80 Type 1 | 95,000 psi (655 MPa) | 80,000 psi (552 MPa) | 23 HRc | Controlled yield, corrosion-resistant for sour service (H₂S environments). |

Common Casing Pipe Dimensions and Weights (API 5CT)

Below is a sample of common sizes. Our range includes a comprehensive array of dimensions, including 5 1/2 casing pipe for sale and many others, to suit various well designs.

| Nominal OD (inch) | Wall Thickness (inch) | Weight (lb/ft) | Drift Diameter (inch) | Connection Type |

|---|---|---|---|---|

| 4 1/2 | 0.250 | 9.50 | 3.875 | BTC |

| 5 | 0.244 | 11.50 | 4.375 | BTC |

| 5 1/2 | 0.275 | 15.50 | 4.750 | BTC |

| 7 | 0.317 | 23.00 | 6.250 | BTC |

| 9 5/8 | 0.352 | 36.00 | 8.797 | BTC |

Each pipe also undergoes internal diameter drift testing to ensure compatibility with downhole tools and equipment, a critical aspect for operational efficiency.

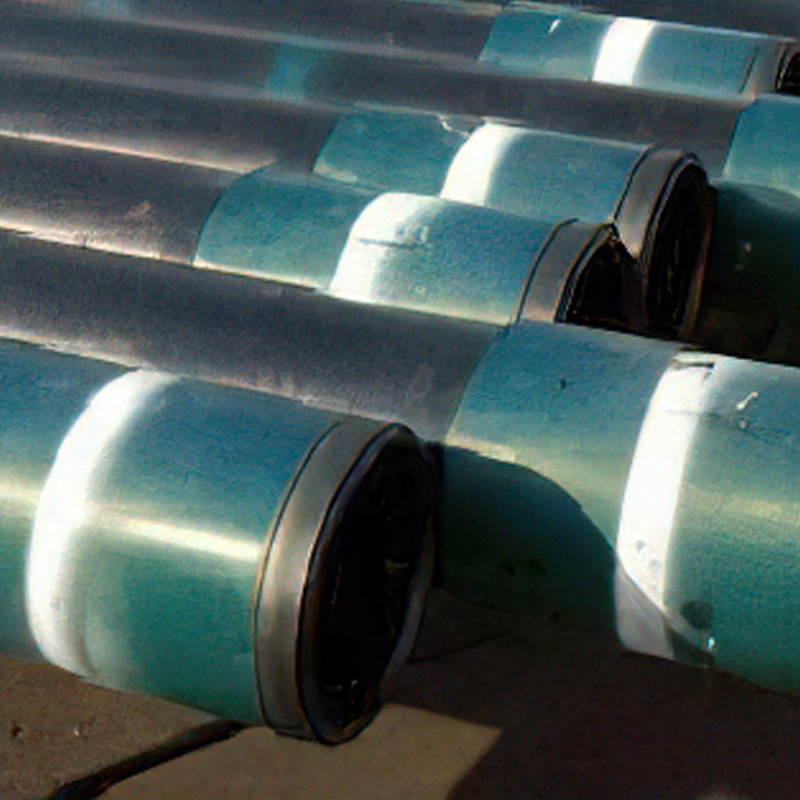

Figure 3: A shipment of premium casing pipe ready for dispatch.

Diverse Application Scenarios and Engineered Advantages

The versatility of high-grade API 5CT well casing pipe for sale makes it indispensable across a spectrum of critical applications. From the depths of hydrocarbon reservoirs to essential water infrastructure, these pipes form the backbone of reliable and safe operations.

Oil and Gas Exploration & Production

In the oil and gas industry, casing pipe serves multiple functions: stabilizing the wellbore, preventing fluid loss into formations, isolating different pressure zones, and providing a conduit for production tubing. High-strength grades like N80 and L80 are crucial for deep, high-pressure, high-temperature (HPHT) wells, particularly in corrosive sour gas environments where L80's controlled hardness offers superior sulfide stress cracking (SSC) resistance. The robust BTC connection ensures structural integrity under extreme axial loads.

Geothermal Wells

Geothermal drilling demands casing pipe that can withstand exceptionally high temperatures, often exceeding 200°C, and exposure to corrosive geothermal fluids. Specialized casing pipes prevent thermal degradation and chemical attack, ensuring long-term energy extraction efficiency. The inherent corrosion resistance and dimensional stability of our pipes are critical here.

Water Well and Borewell Construction

For water extraction, casing pipe for borewell applications ensures the well's structural stability and prevents contamination of the water supply from surrounding soil and rock. While grades like J55 are often sufficient for shallower wells, deeper municipal or industrial water wells may benefit from K55 or N80 for enhanced longevity and reliability, especially in challenging geological formations. The smooth internal surface of our pipes minimizes flow resistance, contributing to energy efficiency in pumping operations.

Figure 4: Casing pipe installation for a large-scale water borewell project.

Technical Advantages: What Sets Our Casing Apart

- Superior Material Composition: Utilizing advanced steel alloys and stringent control over chemical composition, ensuring optimal strength-to-weight ratio and specific environmental resistances.

- Advanced Threading Technology (BTC): Our Buttress Thread Coupling (BTC) offers excellent tensile strength, sealing capability, and ease of make-up, crucial for preventing leakage and ensuring structural integrity under high loads.

- Exceptional Corrosion Resistance: For grades like L80, strict hardness controls and material selection mitigate sulfide stress cracking (SSC) and enhance general corrosion resistance, prolonging service life and reducing maintenance costs.

- Consistent Dimensional Accuracy: Precision manufacturing and rigorous quality checks ensure uniform wall thickness, straightness, and exact OD/ID, leading to smoother installation and superior downhole performance.

- Enhanced Collapse Resistance: Engineered for superior resistance to external pressures, critical for deep wells where lithostatic and formation pressures are significant.

- Reduced Total Cost of Ownership (TCO): High reliability, extended service life, and reduced downtime contribute to a significantly lower TCO over the operational lifespan of the well.

Choosing the Right Supplier: A Vendor Comparison for Casing Pipe

The market for well casing pipe for sale is competitive, making vendor selection a critical decision. Beyond price, factors such as quality, reliability, technical support, and customization capabilities are paramount. Here's a comparison framework to guide your procurement.

Key Differentiators in Casing Pipe Suppliers

| Feature | World Steel Material (Our Offering) | Typical Competitor A | Typical Competitor B |

|---|---|---|---|

| API 5CT Certification | Full API 5CT compliance for all listed grades (J55, K55, N80, L80). Comprehensive documentation. | Often API certified for standard grades, limited documentation for specialized batches. | May offer "API equivalent" or older revisions, potential gaps in rigorous testing. |

| Manufacturing Process Control | In-house seamless production, advanced heat treatment, precision CNC threading, 100% NDT. | May outsource some stages, less integrated quality control. | Reliance on external third-party mills, inconsistent process oversight. |

| Customization Options | Extensive customization for OD, WT, length, thread types (BTC, LTC, STC), and coatings. | Limited customization to standard parameters, higher MOQ for specials. | Generally mass-produced standard products, minimal customization. |

| Technical Support & Expertise | Dedicated engineering support, technical consultation, application guidance. Over 20 years of industry experience. | Basic sales support, limited in-depth technical assistance. | Primarily transactional, little to no technical advisory. |

| Lead Time & Logistics | Efficient supply chain, global logistics partnerships, reliable lead times (2-4 weeks for standard, 6-10 for custom). | Variable lead times, potential delays in international shipping. | Longer lead times due to less optimized logistics, less transparency. |

| Warranty & After-Sales | Comprehensive product warranty, responsive customer service, field support. | Standard limited warranty, slower response times. | Minimal warranty, challenging post-purchase support. |

This comparison highlights why selecting a reputable supplier for your casing pipe for sale is a strategic investment in your project's long-term success and operational integrity.

Tailored for Success: Customized Casing Pipe Solutions

While standard API 5CT specifications cover a broad range of applications, many drilling projects encounter unique geological, environmental, or operational challenges that necessitate customized casing solutions. Recognizing this, leading manufacturers offer bespoke options for well casing pipe for sale to optimize performance and overcome specific hurdles.

- Specialized Dimensions: Beyond standard OD and wall thickness, we can produce pipes with precise, non-API dimensions to fit specific well designs or to transition between different sections of the wellbore, including unique requirements like a particular 5 1/2 casing pipe for sale with non-standard wall thickness.

- Advanced Threading Systems: While BTC is robust, specialized connections like premium gas-tight seals or specific proprietary threads can be integrated to enhance seal integrity in extreme pressure or thermal cycling environments.

- Internal and External Coatings: For highly corrosive conditions (e.g., H₂S, CO₂, high salinity), custom internal plastic coatings (IPC) or external anti-corrosion coatings (e.g., fusion bond epoxy, 3LPE) can significantly extend pipe life and protect against aggressive media.

- Material Enhancements: For ultra-deep wells or highly sour service, material composition can be further refined with higher alloy content (e.g., Cr, Mo, Ni) to achieve even greater strength, toughness, and corrosion resistance beyond standard API grades.

- Specific Lengths: Custom pipe lengths can reduce the number of connections required in a well, saving make-up time and reducing potential leak points.

- Rigorous Supplementary Testing: For critical applications, additional testing beyond API requirements (e.g., full-scale collapse testing, impact testing at low temperatures, specific H₂S partial pressure tests) can be performed to validate performance under exact operating conditions.

Our engineering team collaborates closely with clients to understand their unique challenges, offering expert guidance and developing custom manufacturing solutions that deliver superior performance and reliability.

Real-World Impact: Application Case Studies

The proven performance of our API 5CT casing pipe in diverse and demanding scenarios underscores our commitment to quality and reliability. Here are a few examples showcasing the practical advantages.

Case Study 1: Deepwater Oil & Gas Exploration (HPHT Well)

Challenge: A major offshore operator required high-strength, corrosion-resistant casing for a deepwater exploration well with expected bottom-hole temperatures exceeding 150°C and pressures up to 15,000 psi, with anticipated H₂S presence. Standard grades risked sulfide stress cracking and collapse failure.

Solution: We supplied API 5CT L80 Type 1 casing pipe with enhanced internal plastic coating (IPC) for the production string, along with N80 BTC casing for intermediate sections. The L80's controlled hardness (max 23 HRc) ensured excellent SSC resistance, while the IPC provided an additional barrier against corrosive fluids.

Result: The well was successfully drilled and completed, demonstrating exceptional wellbore integrity. Our L80 casing provided the necessary strength and corrosion protection, ensuring a stable and productive well. The client reported significant confidence in the material's long-term performance under extreme conditions.

Case Study 2: Municipal Water Borewell in Arid Region

Challenge: A municipal project in a drought-stricken area needed a deep water well (500 meters) to secure a reliable potable water supply. The geological formation included unstable sandy layers and some mild corrosive groundwater. The primary concern was long-term stability and prevention of sand ingress.

Solution: We provided API 5CT J55 casing pipe for borewell applications, ensuring robust structural support. For critical permeable zones, we also supplied J55 casing with precision-slotted perforations, ensuring water inflow while preventing sand production. All pipes were delivered with a standard protective varnish to mitigate surface corrosion during handling and storage.

Result: The borewell was successfully completed, providing a clean and stable water source for the community. The chosen J55 casing offered optimal performance and cost-effectiveness for the given environment, with the slotted sections efficiently managing sand control. The project achieved its objective of a sustainable water supply, attributing part of its success to the reliability of the casing.

Figure 5: High-strength casing pipe being prepared for downhole deployment.

Authoritativeness and Trustworthiness: Our Commitment

At World Steel Material, our commitment to quality and customer satisfaction is built on a foundation of industry authority, rigorous certification, and transparent operational practices.

Certifications and Compliance

Our API 5CT L80/N80/J55/K55 BTC Casing and Tubing Pipe products are manufactured in strict accordance with the American Petroleum Institute (API) Specification 5CT, a globally recognized standard for casing and tubing. Additionally, our manufacturing facilities hold ISO 9001 certification, demonstrating our adherence to international quality management systems. All products undergo third-party inspection and certification upon request, providing an additional layer of assurance.

Partners and Years of Service

With over two decades of experience in the steel material industry, we have established long-standing partnerships with leading oil & gas companies, national energy enterprises, and major water infrastructure developers across the globe. Our consistent delivery of high-quality casing pipe for sale has earned us a reputation as a trusted and reliable supplier.

Customer Feedback and Testimonials

"World Steel Material consistently delivers top-tier API 5CT casing. Their technical support team helped us specify the exact L80 grade for a challenging sour gas project, and the performance was flawless. A truly reliable partner." - Lead Engineer, International Oil Company

"We needed a custom batch of 5 1/2 casing pipe for sale with specific threading and received them on time, perfectly meeting our project's tight schedule. The quality was outstanding." - Procurement Manager, Water Infrastructure Group

Lead Time and Fulfillment

Our robust supply chain and optimized production schedule enable us to offer competitive lead times. For standard API 5CT casing pipe, typical lead times range from 2 to 4 weeks. For highly customized orders or large-volume projects, lead times are generally 6 to 10 weeks, depending on specific requirements and current production load. We provide real-time updates and dedicated logistics support to ensure timely delivery to your project site, anywhere in the world.

Warranty and Customer Support

We stand behind the quality of our products with a comprehensive 12-month warranty against manufacturing defects, effective from the date of delivery. Our dedicated customer support team is available 24/7 to address any inquiries, provide technical assistance, and facilitate after-sales services. We believe in building lasting relationships through unparalleled support and commitment.

Frequently Asked Questions (FAQ) about Well Casing Pipe

Q1: What is the primary difference between J55, K55, N80, and L80 casing pipe?

A1: The primary difference lies in their mechanical properties, specifically yield strength and tensile strength, and for L80, its controlled hardness for sour service applications. J55 and K55 are suitable for moderate depth wells, with K55 offering higher tensile strength. N80 is an intermediate strength grade. L80 (Type 1) has similar strength to N80 but is specially treated and hardness-controlled to resist sulfide stress cracking (SSC) in environments containing hydrogen sulfide (H₂S), making it ideal for sour service.

Q2: What does BTC mean in the context of casing pipe?

A2: BTC stands for Buttress Thread Coupling. It is a common thread connection type for casing pipe known for its high strength, excellent sealing capability, and ease of make-up. It's designed to withstand significant axial loads and internal/external pressures, making it suitable for many well applications.

Q3: How do I choose the correct casing pipe size and grade for my project?

A3: Selection depends on various factors: well depth, anticipated downhole pressures and temperatures, corrosive agents (e.g., H₂S, CO₂), formation stability, and fluid type. It's crucial to perform detailed well design calculations and consult with a drilling engineer. Our technical team can also provide expert guidance based on your specific project parameters, helping you identify the most appropriate casing pipe for sale.

Q4: Are your casing pipes compliant with international standards?

A4: Yes, all our API 5CT L80/N80/J55/K55 BTC Casing and Tubing Pipe are manufactured and tested in full compliance with the American Petroleum Institute (API) Specification 5CT. Our facilities also maintain ISO 9001 quality management system certification, ensuring consistent adherence to global quality benchmarks.

Q5: Can you provide custom lengths or coatings for casing pipe?

A5: Absolutely. We specialize in customized solutions to meet unique project requirements. This includes custom pipe lengths to optimize installation, specific wall thicknesses (e.g., for a 5 1/2 casing pipe for sale with enhanced burst resistance), specialized internal or external anti-corrosion coatings, and alternative thread designs. Please contact our sales or engineering team with your detailed specifications.

Conclusion

The selection of high-quality well casing pipe for sale is a critical decision that directly impacts the safety, efficiency, and longevity of any wellbore project. By understanding the intricate manufacturing processes, adhering to stringent API 5CT standards, and leveraging advanced materials like L80 for sour service, operators can ensure optimal downhole integrity. Partnering with a reputable supplier like World Steel Material, known for its expertise, comprehensive product range, customization capabilities, and unwavering commitment to customer support, is key to achieving project success and minimizing long-term operational risks.

References

- American Petroleum Institute. API Specification 5CT: Specification for Casing and Tubing. 10th Edition, 2018.

- NACE International. MR0175/ISO 15156: Petroleum and natural gas industries—Materials for use in H2S-containing environments in oil and gas production. 2020.

- SPE Journal. "Advanced Materials for Deep and Challenging Wells: A Review of Casing and Tubing Innovations." Society of Petroleum Engineers, Vol. 25, No. 3, 2020, pp. 450-465.

- Geothermal Resources Council Bulletin. "Casing Design Considerations for High-Temperature Geothermal Wells." Vol. 49, No. 4, 2020, pp. 25-30.

- Water Well Journal. "Selecting Casing for Durable Water Wells: Material and Connection Choices." National Ground Water Association, Vol. 74, No. 2, 2020, pp. 32-38.

Post time: Aug . 31, 2025 06:20