Hydraulic Pipe Fittings Machine is a key solution in the manufacturing industry, specifically within Special Equipment Manufacturing Industry and Manufacturing of metal processing machinery. This article explores how Beijing Sinoworld Steel Material Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Hydraulic Pipe Fittings Machine Overview

- Benefits & Use Cases of Hydraulic Pipe Fittings Machine in Manufacturing of metal processing machinery

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Hydraulic Pipe Fittings Machine from Beijing Sinoworld Steel Material Co., Ltd.

Hydraulic Pipe Fittings Machine Overview

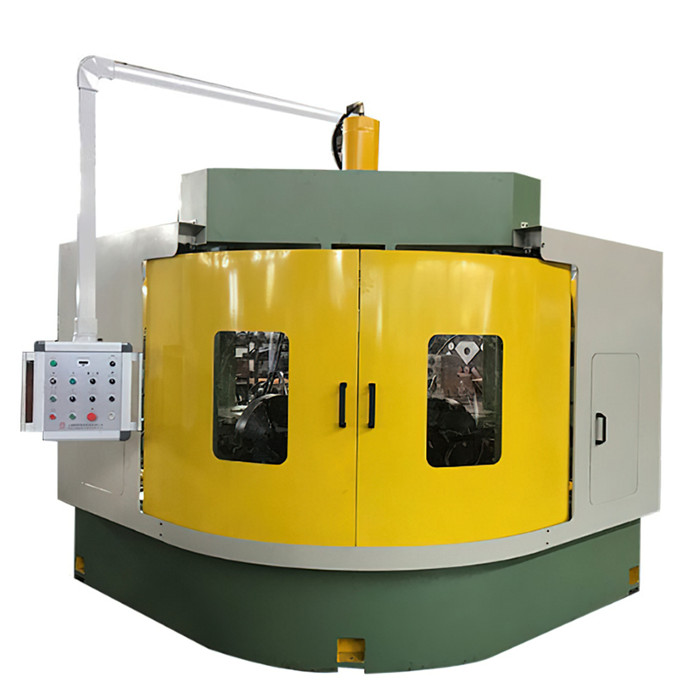

A Hydraulic Pipe Fittings Machine is engineered to form, bevel, trim, and finish pipe fittings—such as elbows, tees, reducers, and caps—with consistent geometry and repeatable accuracy. For decision makers in the Manufacturing of metal processing machinery segment, it is the backbone for scaling output while controlling quality across carbon steel, alloy steel, and stainless-steel product lines. Modern systems integrate servo-hydraulic actuation, PLC/IPC controls, and operator-friendly HMIs to automate cycles and store recipes, minimizing operator variability and changeover times.

Depending on configuration, these machines support a broad diameter range and wall thicknesses typical for pressure piping, with quick-change tooling enabling fast switchovers between SKU families. Optional stations—like integrated beveling heads, mandrel expansion for a tee forming machine workflow, or precision trimming—tighten tolerances and reduce secondary operations. Beijing Sinoworld Steel Material Co., Ltd., a trusted supplier in the Special Equipment Manufacturing Industry, delivers robust frames, balanced hydraulics, and practical safety interlocks designed for multi-shift environments. Their focus on durability, ease of maintenance, and stable hydraulic control translates into fewer unplanned stoppages and higher first-pass yield for industrial users.

Benefits & Use Cases of Hydraulic Pipe Fittings Machine in Manufacturing of metal processing machinery

Across fabrication shops, fitting mills, and OEM component lines, Hydraulic Pipe Fittings Machines streamline critical operations: forming branches for tees, beveling weld-prep angles, calibrating ovality, and trimming ends to length. In a tee forming machine setup, controlled hydraulic expansion ensures uniform branch dimensions and wall distribution, improving weldability and downstream assembly. In beveling applications, programmable angle, land, and surface finish settings yield consistent joints that reduce fit-up time on site—vital for oil & gas, shipbuilding, HVAC, water infrastructure, and power generation projects.

- Competitive advantages: high forming force with servo control, quick-change tooling, integrated bevel/trim stations, and recipe-driven repeatability across shifts.

- Quality outcomes: improved dimensional stability, better surface integrity, and reduced rework scrap.

- Throughput gains: shorter cycle times and less material handling due to in-line finishing.

Beijing Sinoworld Steel Material Co., Ltd. brings application know-how from diverse sectors, guiding B2B buyers on tooling selection, hydraulic settings, and line layouts. Their portfolio, including dedicated beveling solutions linked from the product page above, is configured to slot into existing cells or serve as the foundation for new fitting lines.

Cost, Maintenance & User Experience

Total cost of ownership for a Hydraulic Pipe Fittings Machine hinges on energy use, tooling life, uptime, and consumables (oil, seals, cutters). Systems from Beijing Sinoworld Steel Material Co., Ltd. emphasize robust hydraulics and balanced drives to extend service intervals, while recipe storage reduces set-up losses and scrap during changeovers. Over the machine life, these factors support a favorable ROI by consolidating multiple operations (forming, beveling, trimming) and cutting secondary handling.

- Durability: rigid frames resist deflection under high-tonnage cycles, preserving accuracy and tool life.

- Maintenance: accessible filter blocks, standardized seals, clear hydraulic routing, and centralized lubrication simplify scheduled service.

- User experience: intuitive HMI, alarm diagnostics, and guided set-up shorten training curves for operators.

Customers in the Special Equipment Manufacturing Industry often note stable bevel quality across shifts and fewer corrective passes at welding. Maintenance teams appreciate straightforward parts sourcing and technical support, which reduces downtime during planned overhauls. Combined, these attributes help B2B leaders justify capex with measurable gains in throughput, quality, and predictability of delivery schedules.

Sustainability & Market Trends in manufacturing

Pressure is mounting on metalworking operations to deliver more with less energy, fewer consumables, and lower waste. In hydraulic forming and beveling, trends include servo-hydraulic optimization to cut idle energy draw, leak-minimizing manifolds, biodegradable hydraulic fluids where applicable, and tighter chip management for responsible disposal. Digital features—cycle counters, thermal monitoring, and predictive maintenance—further reduce unplanned emissions from emergency service calls and scrap generation from out-of-tolerance runs.

Beijing Sinoworld Steel Material Co., Ltd. aligns with these priorities by focusing on efficient hydraulic circuits, durable tooling interfaces that extend service life, and remote support options that help teams resolve issues quickly. As Manufacturing of metal processing machinery evolves, forward-looking machine designs that integrate data visibility and energy-aware control strategies provide a competitive edge—supporting compliance with evolving regulations while strengthening brand reputation for sustainability.

Conclusion on Hydraulic Pipe Fittings Machine from Beijing Sinoworld Steel Material Co., Ltd.

For B2B decision makers in the Special Equipment Manufacturing Industry, a Hydraulic Pipe Fittings Machine delivers the precision, throughput, and reliability required to scale fittings production—whether forming tees, beveling weld preps, or finishing reducers. Beijing Sinoworld Steel Material Co., Ltd. combines practical engineering with attentive support, helping manufacturers reduce total cost of ownership and accelerate ROI.

- Partner with a proven manufacturer for your Manufacturing of metal processing machinery initiatives.

- Contact us: email: garvinliu@world-steelmaterial.com

- Visit our website: https://www.world-steelmaterial.com

Post time: Nov . 09, 2025 06:50