Understanding bulk galvanized pipe: Market Dynamics and Key Trends

In the robust landscape of modern infrastructure and industrial applications, the demand for durable and corrosion-resistant piping solutions is paramount. Among these, bulk galvanized pipe stands out as a critical component, offering exceptional longevity and performance in diverse environments. This article delves into the technical intricacies, application versatility, and strategic advantages of hot-dipped galvanized steel pipes, a staple for discerning B2B decision-makers and engineering professionals.

The global market for galvanized steel products, including galvanized pipe, continues to exhibit steady growth, driven by burgeoning urbanization, industrial expansion, and an increasing emphasis on sustainable, long-life material solutions. Recent market analyses indicate a Compound Annual Growth Rate (CAGR) of approximately 4.5% for galvanized steel from 2023 to 2028, with significant contributions from infrastructure projects, energy sectors, and residential/commercial construction. This sustained demand underlines the importance of reliable `galvanized pipe wholesale` suppliers capable of delivering high-quality `galvanized pipe types` in volume.

Key industry trends underscore a shift towards materials offering superior corrosion protection and reduced maintenance costs. Environmental regulations also favor materials with extended service lives, minimizing resource consumption and waste. The versatility of galvanized tubing makes it indispensable across various sectors, from intricate plumbing systems to heavy-duty structural applications. Understanding these dynamics is crucial for optimizing procurement strategies and ensuring project success.

The Advanced Manufacturing Process of Bulk Galvanized Pipe

The superior performance of bulk galvanized pipe is rooted in its meticulously controlled manufacturing process, primarily hot-dip galvanization. This method involves coating fabricated steel with a layer of zinc, creating a metallurgical bond that provides robust protection against corrosion. The process is a series of precisely engineered steps:

- Surface Preparation (Cleaning): Raw steel pipes, typically manufactured via Electric Resistance Welded (ERW) or seamless methods, undergo a rigorous cleaning process. This involves degreasing in an alkaline solution to remove oils and dirt, followed by acid pickling (usually hydrochloric or sulfuric acid) to eliminate mill scale and rust. This step is crucial for achieving optimal zinc adhesion.

- Fluxing: After pickling, pipes are immersed in a flux solution, typically zinc ammonium chloride. The flux cleans the steel surface further, preventing oxidation before galvanizing and promoting a more uniform, complete zinc coating.

- Hot-Dip Galvanizing: The prepared pipes are then submerged in a molten zinc bath maintained at approximately 450°C (840°F). During this immersion, the iron in the steel metallurgically reacts with the molten zinc to form a series of intermetallic alloy layers, followed by an outer layer of pure zinc. This alloy layer is exceptionally hard and abrasion-resistant, providing superior protection compared to surface coatings.

- Cooling and Finishing: Upon withdrawal from the zinc bath, the pipes are cooled, often in water or ambient air, to solidify the zinc coating. Excess zinc is removed through various methods such as steam or air wipers for the inner diameter (ID) and external wiping for the outer diameter (OD), ensuring a smooth, consistent finish.

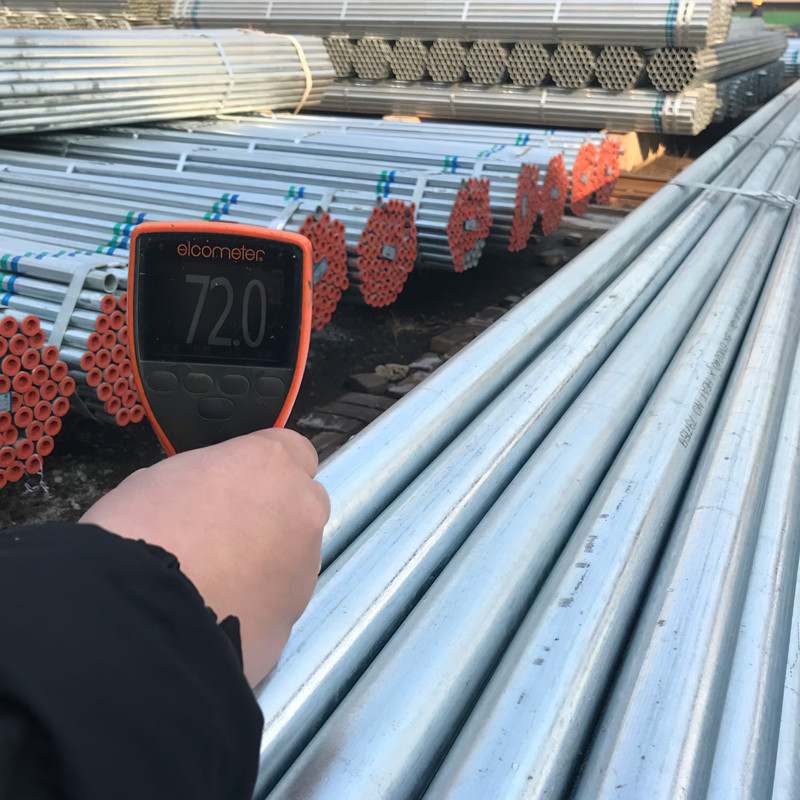

- Inspection: Each galvanized pipe undergoes stringent quality control inspections. This includes visual checks for coating uniformity and surface defects, coating thickness measurement (e.g., using magnetic gauges), adhesion tests, and potentially mechanical property tests (e.g., bending, flattening). Testing standards like ISO 1461, ASTM A123, and ASTM A53 are rigorously applied to ensure product integrity and compliance.

The primary materials for these pipes are typically carbon steel grades such as ASTM A53 (Grade A and B), ASTM A106, and API 5L, chosen for their excellent weldability and structural properties. This process yields an average service life of 50 years or more in typical atmospheric conditions, significantly outperforming ungalvanized steel. Target industries include petrochemical, metallurgy, water supply & drainage, construction, and agriculture, where their energy-saving corrosion resistance and minimal maintenance requirements translate into substantial long-term cost advantages.

Technical Specifications and Performance of Galvanized Pipe

The performance and suitability of bulk galvanized pipe for specific applications are defined by a range of critical technical specifications. These parameters ensure engineers can select the appropriate `galvanized pipe types` for optimal system design and longevity.

Typical Product Specifications for Hot-Dipped Galvanized Steel Pipes

| Parameter | Specification Range/Details | Relevant Standards |

|---|---|---|

| Material Grade | ASTM A53 Gr. A/B, EN 10255 S195T, Q235B, API 5L Gr. B | ASTM, EN, API |

| Outer Diameter (OD) | DN15 - DN600 (NPS 1/2" - 24"); 21.3 mm - 610 mm | ANSI B36.10M, EN 10220 |

| Wall Thickness (WT) | 2.11 mm - 20 mm (Schedule 10 to XXS) | ANSI B36.10M, EN 10220 |

| Length | 5.8m, 6m, 12m, or customized lengths | Customer Specification |

| Zinc Coating Thickness | Average 45 µm to 120 µm (typically 275 g/m² to 840 g/m²) | ISO 1461, ASTM A123, AS/NZS 4680 |

| End Finish | Plain end, Beveled end, Threaded (with coupling), Grooved | ASME B1.20.1, AWWA C606 |

| Yield Strength | 240 MPa - 355 MPa (35-50 ksi) min. | ASTM A53, EN 10255 |

| Tensile Strength | 415 MPa - 520 MPa (60-75 ksi) min. | ASTM A53, EN 10255 |

The robust metallurgical bond between the steel substrate and the zinc coating provides a dual layer of protection: a passive barrier and active cathodic protection. Should the coating be scratched, the surrounding zinc sacrifices itself to protect the exposed steel, preventing rust migration. This self-healing property significantly extends the service life of galvanized pipe, making it a highly reliable choice for demanding applications where exposure to corrosive elements is common. Rigorous hydrostatic testing ensures the pipes can withstand specified internal pressures without leakage or failure, confirming their integrity for fluid transport systems.

Versatile Application Scenarios for Bulk Galvanized Pipe

The adaptability and resilience of bulk galvanized pipe make it an indispensable material across a spectrum of industries. Its inherent corrosion resistance and structural integrity provide reliable performance in environments where other materials would quickly degrade.

Key Application Areas:

- Water Supply and Drainage Systems: Widely used for municipal water distribution, potable water lines (where approved by local regulations), wastewater treatment facilities, and industrial process water lines. The zinc coating prevents internal corrosion, maintaining water quality and flow rates over decades.

- Oil and Gas Industry (Non-corrosive Fluids & Structural): While direct contact with certain aggressive petroleum products is avoided, galvanized pipe is used for structural supports, fencing, and conduit in oil and gas facilities, as well as for transporting natural gas or other non-corrosive fluids.

- Construction and Structural Applications: Essential for scaffolding, handrails, guardrails, security fencing, structural frameworks, and supports in various building projects. The robustness of galvanized tubing makes it ideal for load-bearing and protective structures.

- Agricultural Sector: Employed in irrigation systems, greenhouse structures, livestock enclosures, and fencing where exposure to moisture and harsh outdoor conditions demands durable materials.

- HVAC and Fire Protection Systems: Used in chilled water lines, ductwork, and sprinkler systems, providing a reliable and compliant solution for fire safety and climate control infrastructure.

Application Case Studies:

Case Study 1: Municipal Water Infrastructure Upgrade

A major metropolitan area undertook a comprehensive upgrade of its aging water distribution network, replacing ductile iron and older steel pipes. For secondary distribution lines and service connections, over 500,000 linear feet of DN150 (6-inch) bulk galvanized pipe conforming to ASTM A53 Gr. B was specified. The primary drivers for this selection were the pipe's projected 60-year lifespan, its superior resistance to tuberculation and internal corrosion compared to uncoated steel, and its lower initial cost relative to stainless steel. The project, completed within budget, has significantly reduced leak rates and improved water quality, demonstrating the long-term economic and operational benefits of `galvanized pipe`.

Case Study 2: Industrial Chemical Plant Walkway and Safety Railings

An expansion project at a chemical processing plant, operating in a highly corrosive atmosphere, required robust and durable safety railings and elevated walkways. Instead of painted steel, which would necessitate frequent re-coating, the engineering team opted for `galvanized tubing` (Schedule 40, ASTM A53) for all structural and handrail elements. The inherent sacrificial protection of the zinc coating against acid rain and chemical fumes ensured minimal maintenance and a pristine appearance over time. This decision led to a 40% reduction in projected maintenance costs over 20 years and enhanced worker safety through consistently intact safety barriers, showcasing the practical advantages of galvanized pipe in harsh industrial settings.

Technical Advantages and Competitive Edge

The selection of bulk galvanized pipe over alternative materials is driven by several compelling technical advantages that translate directly into operational efficiencies and long-term cost savings for B2B applications.

- Superior Corrosion Resistance: The hot-dip galvanization process creates a metallurgically bonded zinc coating that acts as both a barrier and offers cathodic protection. This dual defense mechanism makes galvanized pipe exceptionally resistant to rust and corrosion, even in challenging environments like coastal areas or industrial settings.

- Extended Service Life: With proper installation and maintenance, `galvanized pipe` can provide reliable service for 50 to 100 years, significantly longer than ungalvanized steel or some plastic alternatives. This longevity reduces the frequency and cost of replacements.

- Cost-Effectiveness: While the initial cost may be slightly higher than plain carbon steel, the vastly reduced maintenance requirements and extended lifespan of `galvanized pipe` result in a much lower total cost of ownership (TCO) over the project's life cycle.

- Durability and Mechanical Strength: Retaining the inherent strength of steel, galvanized tubing offers excellent impact resistance and structural integrity, crucial for applications under stress or in exposed conditions.

- Easy Inspection and Maintenance: The integrity of the galvanized coating is easily assessed visually, simplifying maintenance routines and ensuring potential issues are identified early.

Material Comparison: Galvanized Pipe vs. Alternatives

| Feature | Hot-Dipped Galvanized Pipe | Black Steel Pipe (Uncoated) | Stainless Steel Pipe | PVC Pipe |

|---|---|---|---|---|

| Corrosion Resistance | Excellent (Active & Passive) | Poor (Rusts easily) | Superior (Passive Chromium Layer) | Excellent (Chemical Resistance) |

| Service Life | 50-100+ years | 10-20 years (with painting) | 100+ years | 50+ years (UV degradation concern) |

| Initial Cost | Medium | Low | High | Low |

| Maintenance Needs | Very Low | High (Regular painting) | Very Low | Low (Cleaning) |

| Strength & Rigidity | High | High | High | Low |

This comparison highlights `galvanized pipe's` optimal balance of cost, longevity, and performance, positioning it as a strategically sound investment for many industrial and infrastructural projects, especially when considering the complete lifecycle cost. For applications requiring `galvanized pipe wholesale` quantities, these advantages compound significantly.

Vendor Comparison and Customized Solutions for Galvanized Pipe

Selecting the right `galvanized pipe wholesale` supplier is critical for ensuring product quality, timely delivery, and cost-effectiveness. A thorough vendor comparison should extend beyond mere pricing to encompass technical capabilities, quality assurances, and customer support.

Key Considerations for Vendor Selection:

- Certifications and Compliance: Verify adherence to international standards such as ISO 9001 (Quality Management), ISO 14001 (Environmental Management), ASTM, EN, API, and CE marking. These certifications are indicators of consistent quality and reliable manufacturing processes for all `galvanized pipe types`.

- Production Capacity and Lead Times: Assess the vendor's ability to meet your `bulk galvanized pipe` requirements efficiently. Inquire about typical lead times for standard products and customized orders, as well as their logistical capabilities for large-volume shipments.

- Quality Control and Testing: A reputable supplier will have robust in-house testing facilities for chemical composition, mechanical properties, hydrostatic testing, and zinc coating thickness to ensure every galvanized pipe meets specifications.

- Technical Expertise and Customization: Look for vendors who can offer expert advice on material selection, design optimization, and specialized solutions.

- After-Sales Support and Warranty: Comprehensive warranty policies and responsive customer support are indicative of a reliable long-term partner.

Customized Solutions:

Recognizing that standard products may not always fit unique project requirements, leading suppliers offer extensive customization options for `galvanized pipe`. These tailored solutions ensure optimal fit, function, and efficiency:

- Specific Dimensions: Custom lengths, non-standard diameters, and precise wall thicknesses (e.g., specific schedules not commonly stocked) can be manufactured to minimize waste and installation time.

- End Finishes: Beyond plain, threaded, or grooved ends, custom end preparations for specialized welding or joining systems can be provided for galvanized tubing.

- Enhanced Coatings: For extremely aggressive environments, additional coatings such as epoxy, polyethylene (PE), or paint systems can be applied over the galvanization for a multi-layered protection strategy.

- Fabrication and Pre-assembly: Some suppliers offer pre-fabrication services, including bending, cutting, drilling, and welding of components, which can significantly reduce on-site labor and project timelines.

- Special Packaging: Custom packaging solutions, including protective wraps, wooden crates, or container111ization, can be arranged to ensure `bulk galvanized pipe` arrives at the destination in perfect condition, especially for export or remote sites.

Engaging with a supplier capable of these customized solutions not only streamlines procurement but also provides access to expert advice, ensuring that the chosen galvanized pipe perfectly aligns with the project’s specific demands and operational longevity.

Authoritativeness, Trustworthiness, and Support for Bulk Galvanized Pipe Procurement

Establishing trust and demonstrating authority are paramount in B2B transactions, particularly for critical materials like bulk galvanized pipe. Our commitment to quality is underpinned by adherence to rigorous international standards and a transparent operational framework.

Company and Product Certifications:

Our manufacturing processes and products are certified by leading global authorities, affirming our dedication to excellence. We hold certifications such as ISO 9001:2015 for Quality Management Systems, ensuring consistent product quality and customer satisfaction. Products conform to international standards including ASTM A53, BS 1387, EN 10255, and ISO 1461 for hot-dip galvanization. We are also proud to be a trusted supplier to numerous Fortune 500 companies and government projects globally, reflecting over two decades of specialized experience in steel material supply.

Lead Time and Fulfillment Details:

We understand the critical nature of project timelines. Our typical lead times for standard galvanized pipe orders range from 15 to 45 business days, depending on volume and customization. Expedited services are available for urgent requirements. Our advanced logistics network, collaborating with major shipping lines and freight forwarders, ensures efficient and reliable delivery to global destinations. We provide real-time tracking and dedicated logistics support from order placement to final delivery, minimizing delays and ensuring predictable project execution for all `galvanized pipe types`.

Warranty Commitments:

All our bulk galvanized pipe products come with a comprehensive warranty against manufacturing defects and coating failures under normal operating conditions. Our standard warranty period is 5 years, extendable based on project specifications and specific agreements. This commitment reflects our confidence in the durability and quality of our products, providing peace of mind to our clients.

Customer Support and After-Sales Service:

Our dedication extends beyond delivery. We offer unparalleled customer support, including:

- Dedicated Account Management: A single point of contact for all inquiries, from technical specifications to order tracking.

- Technical Support: Access to our team of metallurgical engineers and product specialists for installation guidance, application troubleshooting, and material compatibility advice for `galvanized tubing`.

- After-Sales Assistance: Prompt resolution of any post-delivery concerns, ensuring complete satisfaction with your `galvanized pipe wholesale` purchase.

Frequently Asked Questions (FAQ) about Galvanized Pipe:

Q1: What is the primary difference between hot-dip galvanized and electro-galvanized pipe?

A1: Hot-dip galvanization involves immersing steel in molten zinc, creating a thick, metallurgically bonded coating with distinct alloy layers, offering superior corrosion resistance and longevity. Electro-galvanization (or electro-plating) applies a thinner zinc coating through an electrolytic process, primarily for aesthetic purposes and milder corrosion protection. For `bulk galvanized pipe` requiring robust performance, hot-dip is the preferred method.

Q2: How does zinc coating thickness affect the lifespan of galvanized pipe?

A2: Zinc coating thickness is directly proportional to the pipe's service life. A thicker coating provides more zinc to sacrifice, extending the period before the base steel is exposed. Standards like ISO 1461 specify minimum thickness requirements (e.g., 45-120 µm) based on pipe dimensions to ensure optimal protection.

Q3: Can bulk galvanized pipe be welded? What precautions are needed?

A3: Yes, `galvanized pipe` can be welded, but with specific precautions. Welding galvanized steel produces zinc fumes, which can be toxic. Proper ventilation, respiratory protection, and adequate fume extraction are essential. The heat of welding also burns off the zinc coating in the immediate area, requiring touch-up with zinc-rich paint or sprays to restore corrosion protection at the weld joint. This is a crucial consideration for `galvanized tubing` installations.

Q4: What are the common testing standards for galvanized pipe?

A4: Key testing standards include ASTM A53 (for welded and seamless steel pipe), ASTM A123 (for hot-dip galvanized coatings), ISO 1461 (for hot-dip galvanized coatings on fabricated iron and steel articles), BS 1387 / EN 10255 (for threaded and plain-end steel tubes), and API 5L for line pipe applications.

Q5: Is galvanized tubing suitable for potable water applications?

A5: While historically used for potable water, the use of `galvanized pipe` for drinking water systems has diminished in favor of materials like copper, PEX, or stainless steel due to potential zinc leaching (especially in soft, acidic water) and the long-term risk of internal scale buildup. Modern regulations and engineering practices often recommend alternatives, though it may still be permissible in some regions and specific scenarios, depending on local codes and water chemistry. Always consult local plumbing codes and engineering specifications for potable water applications.

Conclusion

The continued prominence of bulk galvanized pipe in diverse industrial and infrastructural projects is a testament to its enduring value proposition. Offering an optimal balance of corrosion resistance, structural strength, longevity, and cost-effectiveness, it remains a preferred choice for engineers and procurement specialists worldwide. By understanding its detailed manufacturing process, comprehensive technical specifications, versatile applications, and the benefits of partnering with authoritative suppliers offering customized solutions, businesses can leverage galvanized pipe to achieve superior project outcomes and long-term operational reliability.

Authoritative References:

- American Society for Testing and Materials (ASTM) International. "ASTM A123/A123M-17, Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products."

- International Organization for Standardization (ISO). "ISO 1461:2022, Hot-dip galvanized coatings on fabricated iron and steel articles – Specifications and test methods."

- Galvanizers Association. "The Performance of Hot Dip Galvanized Steel."

- European Committee for Standardization (CEN). "EN 10255:2004, Non-alloy steel tubes suitable for welding and threading."

- American Iron and Steel Institute (AISI). "Steel Pipe Industry Analysis."

Post time: Aug . 28, 2025 06:20