Field Notes: the Elbow plant workhorse everyone’s talking about

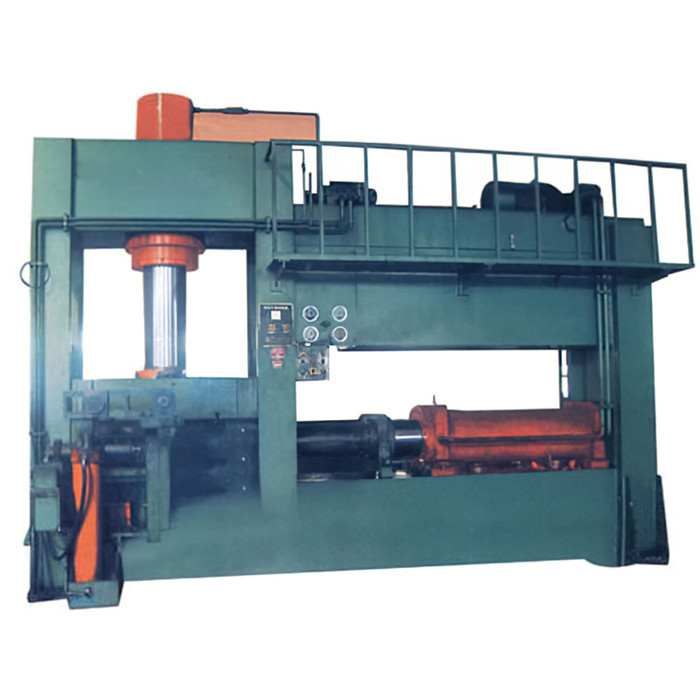

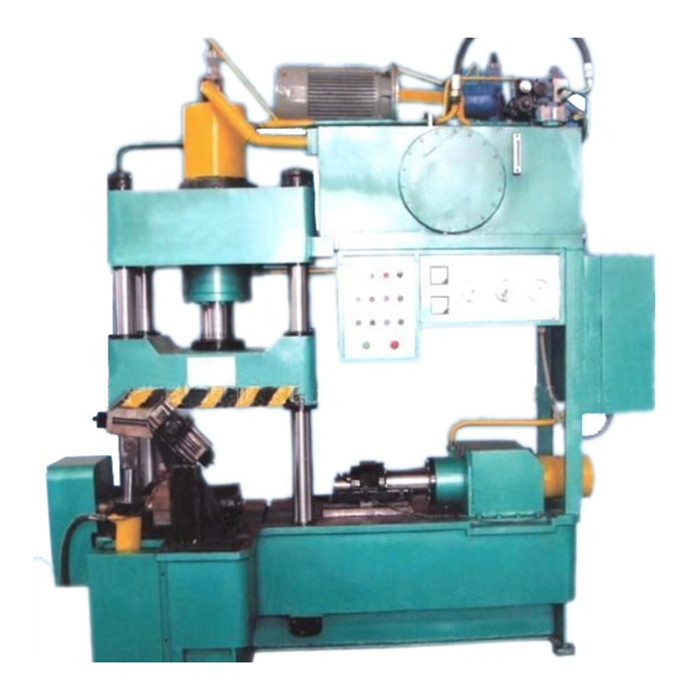

When I first watched an Elbow Cold Forming Machine push redressed billets into perfectly repeatable 90° and 45° elbows, I thought: this is where precision meets brute force. Built in Rm 1103, Shangpintaihu Bld 3#, Tongzhou District, Beijing, this line looks straightforward—but the control logic and die geometry are where the magic hides.

What’s driving the trend

Energy and chemical players are pushing for shorter lead times and tighter ovality. Cold forming answers both: no furnace queue, less scale, and better wall-thickness control. Actually, many customers say they switched from hot push because downstream machining and NDT got simpler. Emissions targets don’t hurt either.

How the process really runs (shop-floor view)

- Materials: CS, stainless, and alloy steels (ASTM A234 grades, EN 10253 families).

- Prep: Saw cut → end bevel/face → lube (phosphate or polymer) → room-temp staging.

- Forming: Hydraulic ram and segmented die set bend and iron the elbow in one controlled stroke.

- Calibration: Secondary pass for angle and ovality; trimming if needed.

- Testing: Dimensional check to ASME B31.3/EN 10253; thickness mapping; dye penetrant for surface; hardness (HB); sometimes UT on critical lots.

- Outputs: Ovality ≤ 1.5%, angle repeatability ±0.3°, thickness reduction typically ≤ 8–12% (grade and radius dependent).

- Service life: With routine oil and seal changes, presses like this run ≈10–12 years before major overhaul, real-world use may vary.

- Industries: Energy supply pipe, petrochem, district heating, shipbuilding, water transmission.

Key specs (the ones buyers actually ask for)

| Parameter | Value |

|---|---|

| Type | Hydraulic cold forming elbow press |

| Power | ≈ 30 kW |

| Voltage | 380 V, 50 Hz (others on request) |

| Dimensions | 5800 × 3200 × 4700 mm |

| Weight | ≈ 2,500 kg |

| Materials handled | CS / SS / alloy steels |

| Typical OD range | Around DN50–DN400 (die-dependent) |

| Angle sets | 45°, 90°, custom radii on request |

| Safety & controls | Meets ISO 4413, IEC 60204-1; e-stop, light curtains (option) |

Vendor landscape (quick, honest comparison)

| Vendor | OD Range | Cycle/Elbow | Warranty | Notes |

|---|---|---|---|---|

| World Steel Material (Elbow Cold Forming Machine) | ≈ DN50–DN400 | 2–5 min (grade/radius dependent) | 12–18 months | Good die library; responsive Beijing service team |

| Regional Maker A | DN25–DN300 | 3–7 min | 12 months | Lower capex; fewer stainless options |

| EU Maker B | DN80–DN600 | 2–4 min | 24 months | Premium price; deep automation suite |

Customization, feedback, and the little things

Options that matter: quick-change die carts, angle calibration gauge, closed-loop pressure control, and IoT uptime tracking. One foreman told me, “We cut scrap by half once we dialed in lube and die temperature—surprisingly, cold forming is sensitive to tiny changes.” Another buyer liked the remote PLC support—because night-shift calls happen.

Mini case study

A district-heating fabricator moved from hot push to a Elbow Cold Forming Machine for DN250 elbows in P235GH. Result after 6 weeks: ovality from 2.2% → 1.1%; thickness thinning from 13% → 8.5%; NDT rejects down 41%. Payback penciled at ~14 months, mostly on rework savings.

Compliance and certifications

Look for ISO 9001 on the build, CE per the Machinery Directive, and electrical compliance to IEC 60204-1. For the elbows you produce, clients will ask about ASTM A234/EN 10253 conformity and ASME B31.3 acceptance. To be honest, documented test plans impress auditors more than any brochure.

References

- ASME B31.3 Process Piping – https://www.asme.org

- ASTM A234/A234M – https://www.astm.org

- EN 10253 Butt-welding pipe fittings – https://standards.cen.eu

- ISO 4413 Hydraulic systems safety – https://www.iso.org

- IEC 60204-1 Safety of machinery electrical – https://www.iec.ch

Post time: Oct . 25, 2025 15:40