hydraulic pipe fittings machine, tee forming machine is a key solution in the manufacturing industry, specifically within Special Equipment Manufacturing Industry and Manufacturing of metal processing machinery. This article explores how Beijing Sinoworld Steel Material Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- hydraulic pipe fittings machine, tee forming machine Overview

- Benefits & Use Cases of hydraulic pipe fittings machine, tee forming machine in Manufacturing of metal processing machinery

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on hydraulic pipe fittings machine, tee forming machine from Beijing Sinoworld Steel Material Co., Ltd.

hydraulic pipe fittings machine, tee forming machine Overview

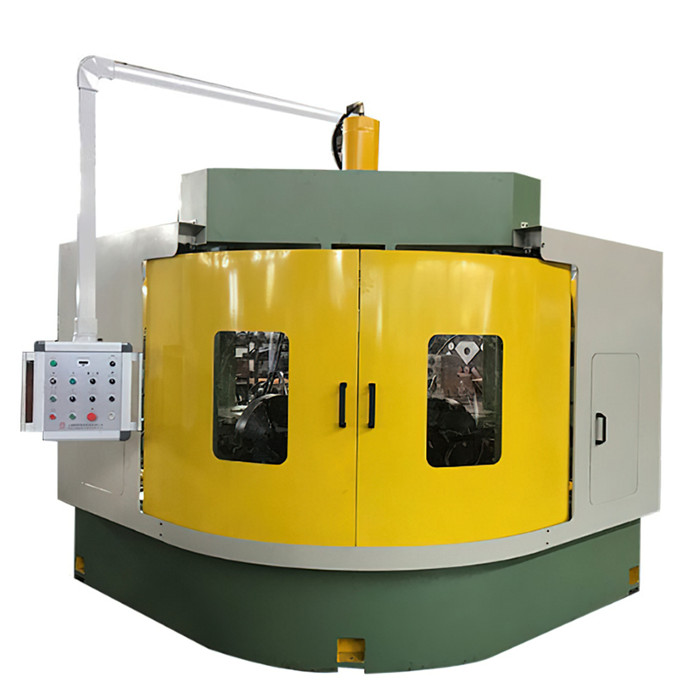

A hydraulic pipe fittings machine is engineered to form elbows, reducers, and tees with high dimensional accuracy via controllable hydraulic force and programmable motion. A tee forming machine focuses on expanding or extruding the branch outlet from a parent pipe, maintaining wall thickness and structural integrity. Together, these systems are foundational in the Special Equipment Manufacturing Industry and the Manufacturing of metal processing machinery, where repeatability, cycle time, and safety are mission-critical.

Modern configurations typically integrate servo-hydraulic drives, PLC/HMI controls, proportional valves for pressure/flow control, and quick-change tooling to cover a wide range of diameters and materials (carbon steel, stainless steel, alloy steel). Inline auxiliary equipment—such as beveling solutions—ensures fittings are production-ready for welding. Beijing Sinoworld Steel Material Co., Ltd. combines robust mechanical frames with precise hydraulic modulation to deliver reliable forming under demanding shop conditions. The company’s product portfolio, including specialized beveling equipment that complements pipe fittings lines, helps B2B decision makers consolidate processes, cut setup time, and standardize quality across SKUs.

Benefits & Use Cases of hydraulic pipe fittings machine, tee forming machine in Manufacturing of metal processing machinery

In metal processing machinery, these systems are deployed in pipeline fabrication, HVAC, energy, petrochemical, and water infrastructure projects. A hydraulic pipe fittings machine produces elbows and reducers aligned to strict tolerances, while a tee forming machine delivers consistent branch geometry suitable for high-pressure applications. The result is improved flow characteristics, better weld prep compatibility, and high structural reliability across production batches.

Key advantages include: - Precision forming with servo-hydraulic control for stable, repeatable cycles. - Quick-change tooling that minimizes downtime between different diameters or standards. - Compatibility with upstream/downstream operations, including cutting, beveling, and NDT. - Safer, enclosed hydraulic systems with interlocks and guarded work areas.

Beijing Sinoworld Steel Material Co., Ltd. brings practical shop-floor know-how to integration. For example, its beveling solutions, such as those featured on the product page, pair seamlessly with tee forming to deliver weld-ready ends, lower rework rates, and smoother handoffs to fabrication or field installation. This process coherence is a competitive edge for manufacturers seeking throughput without compromising quality.

Cost, Maintenance & User Experience

Total cost of ownership (TCO) for a hydraulic pipe fittings machine or tee forming machine extends beyond purchase price. Decision makers weigh energy consumption, tooling life, maintenance intervals, operator training, and uptime. Robust frames, high-quality cylinders, and well-specified seals reduce leaks and pressure loss, translating to fewer stoppages. Smart hydraulic systems with pressure/position monitoring help maintain consistency and reduce scrap, improving ROI.

Customers in the Special Equipment Manufacturing Industry often report that standardized tooling cassettes and intuitive HMIs shorten changeovers and reduce operator learning curves. Predictive maintenance—enabled by sensor feedback for temperature, vibration, and cycle counts—can be planned during off-shifts, minimizing impact on delivery schedules. Beijing Sinoworld Steel Material Co., Ltd. designs for easy service access, clear alarm diagnostics, and spare parts availability, enabling maintenance teams to keep equipment at peak performance. Over an asset’s lifecycle, these human-centered and engineering-led details deliver measurable savings while supporting throughput commitments.

Sustainability & Market Trends in manufacturing

Manufacturers are under growing pressure to reduce energy use and material waste. In hydraulics, this has driven adoption of variable-speed drives, high-efficiency pumps, and optimized pressure management to curb idle losses. Environmentally considerate fluids, improved filtration, and leak-proof designs further reduce the ecological footprint of forming lines. Waste minimization is supported by accurate forming and integrated beveling—helping ensure right-first-time production and less scrap.

Regulatory expectations and certifications (e.g., ISO 9001/14001) are increasingly standard in global supply chains. Meanwhile, market growth in energy transition, municipal water upgrades, LNG, and process industries is elevating demand for precision fittings and reliable tee forming. Beijing Sinoworld Steel Material Co., Ltd. aligns with these trends by engineering durable systems designed for Industry 4.0 connectivity, data logging, and traceability—capabilities that help customers document quality, lower emissions per part, and respond quickly to audits and customer KPIs.

Conclusion on hydraulic pipe fittings machine, tee forming machine from Beijing Sinoworld Steel Material Co., Ltd.

For manufacturers seeking a scalable, precise, and durable solution, a hydraulic pipe fittings machine and tee forming machine underpin consistent quality and higher throughput across fittings production. Beijing Sinoworld Steel Material Co., Ltd. stands out with robust engineering, integration-ready beveling equipment, and responsive support that reduces downtime and boosts ROI. Ready to optimize your line?

Contact us: email: garvinliu@world-steelmaterial.com

Visit our website: https://www.world-steelmaterial.com

Post time: Oct . 16, 2025 11:05