Elbow cold forming machine and hydraulic pipe fittings machine are key solutions in the manufacturing industry, specifically within Special Equipment Manufacturing Industry and Manufacturing of metal forming machine tools. This article explores how Beijing Sinoworld Steel Material Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Elbow Cold Forming Machine & Hydraulic Pipe Fittings Machine Overview

- Benefits & Use Cases of Elbow Cold Forming Machine & Hydraulic Pipe Fittings Machine in Manufacturing of Metal Forming Machine Tools

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Manufacturing

- Conclusion on Elbow Cold Forming Machine & Hydraulic Pipe Fittings Machine from Beijing Sinoworld Steel Material Co., Ltd.

Elbow Cold Forming Machine & Hydraulic Pipe Fittings Machine Overview

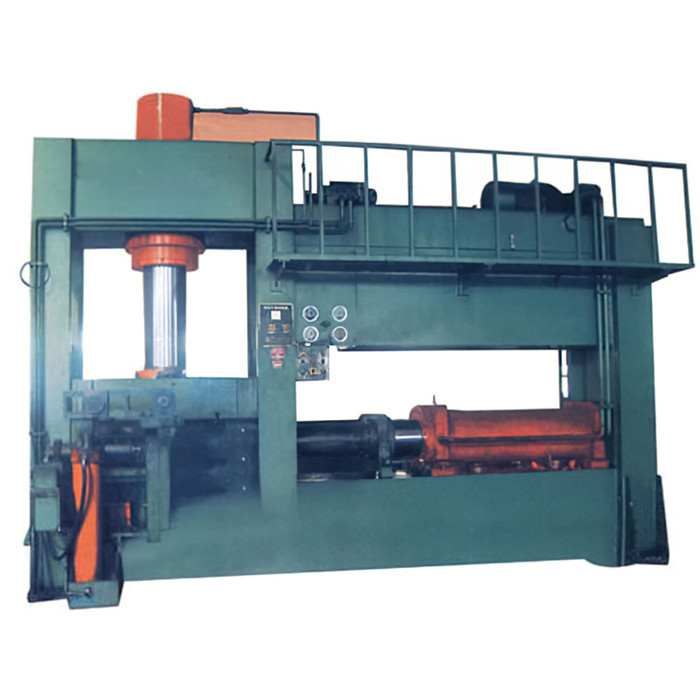

In the demanding landscape of modern manufacturing, precision and efficiency are paramount. The elbow cold forming machine and the hydraulic pipe fittings machine stand as indispensable tools, especially within the Special Equipment Manufacturing Industry and the broader Manufacturing of metal forming machine tools sector. These machines are engineered to produce high-quality pipe elbows and various pipe fittings through advanced cold forming techniques. Unlike hot forming, cold forming ensures superior material integrity, tighter dimensional tolerances, and an excellent surface finish, making the end products ideal for critical applications across industries like oil and gas, chemical processing, power generation, and construction. Beijing Sinoworld Steel Material Co., Ltd. specializes in providing cutting-edge solutions in this domain. Our range of hydraulic pipe fittings machines and elbow cold forming machines incorporates robust hydraulic systems, precise control mechanisms, and durable components. For instance, our machines are designed to process a wide range of materials, including carbon steel, stainless steel, and alloy steel, into various elbow radii and degrees, such as 45, 90, and 180-degree bends. This technical prowess ensures that manufacturing operations can achieve consistent output with minimal material waste, positioning Beijing Sinoworld Steel Material Co., Ltd. as a reliable manufacturer committed to excellence.Benefits & Use Cases of Elbow Cold Forming Machine & Hydraulic Pipe Fittings Machine in Manufacturing of Metal Forming Machine Tools

The integration of an advanced elbow cold forming machine or hydraulic pipe fittings machine offers significant advantages for businesses engaged in the Manufacturing of metal forming machine tools. These machines are crucial for producing the precise bends and complex shapes required for pipe systems that demand high integrity. Specific applications include the fabrication of pipelines for petrochemical plants, shipbuilding, aerospace components, and infrastructure projects, where every joint must withstand extreme pressures and environments. The cold forming process maintains the metallurgical structure of the material, enhancing the strength and longevity of the produced fittings. Our machines at Beijing Sinoworld Steel Material Co., Ltd. are distinguished by several competitive advantages. Features like intuitive PLC control systems ensure ease of operation and precise parameter adjustments, while high-efficiency hydraulic power units deliver consistent force for uniform forming. Furthermore, our elbow cold forming machines are equipped with advanced tooling designs that minimize wear and tear, extending tool life and reducing downtime. We understand the stringent requirements of the Special Equipment Manufacturing Industry, and our expertise allows us to provide solutions that not only meet but exceed industry standards. Choosing Beijing Sinoworld Steel Material Co., Ltd. means opting for reliability, precision, and a partner dedicated to your manufacturing success.

Cost, Maintenance & User Experience

Investing in specialized equipment like an elbow cold forming machine or a hydraulic pipe fittings machine requires a thorough understanding of the total cost of ownership (TCO). At Beijing Sinoworld Steel Material Co., Ltd., we design our machines for exceptional durability and long-term performance, ensuring a superior return on investment (ROI). Our robust construction, utilizing high-grade steel and precision-engineered components, minimizes the need for frequent repairs and extends the operational lifespan of the equipment. This inherent reliability translates directly into reduced downtime and lower maintenance costs over the machine's lifetime. Feedback from our customers in the Special Equipment Manufacturing Industry consistently highlights the user-friendly design and low maintenance requirements of our machinery. Operators appreciate the intuitive interfaces and accessible maintenance points, which simplify routine checks and servicing. This focus on user experience not only boosts productivity but also enhances workplace safety. By minimizing complex troubleshooting and providing comprehensive support, Beijing Sinoworld Steel Material Co., Ltd. ensures that our hydraulic pipe fittings machines and elbow cold forming machines are assets that deliver consistent, high-quality output without excessive operational overheads, offering true value to our clients.Sustainability & Market Trends in Manufacturing

The global manufacturing industry is increasingly prioritizing sustainability and efficiency. Regulations are tightening, and there’s a growing demand for production methods that minimize waste and energy consumption. In this evolving landscape, an advanced elbow cold forming machine offers distinct advantages. Cold forming, by its nature, is often more energy-efficient than hot forming processes, as it eliminates the need for heating large volumes of material to high temperatures. This directly contributes to a reduced carbon footprint, aligning with global sustainability goals. Furthermore, the precision of cold forming reduces material waste, optimizing raw material usage and lowering disposal costs. Beijing Sinoworld Steel Material Co., Ltd. is committed to forward-thinking innovation, ensuring our hydraulic pipe fittings machines and elbow cold forming machines meet the stringent demands of modern manufacturing. We continuously invest in R&D to enhance energy efficiency, incorporate smarter automation, and improve overall operational environmental impact. Our equipment is designed to not only increase productivity but also to support our clients in achieving their own sustainability objectives. As the manufacturing sector moves towards greener practices and increased automation, Beijing Sinoworld Steel Material Co., Ltd. remains at the forefront, providing eco-conscious and technologically advanced solutions for the production of critical pipe fittings.Conclusion on Elbow Cold Forming Machine & Hydraulic Pipe Fittings Machine from Beijing Sinoworld Steel Material Co., Ltd.

The strategic investment in a high-quality elbow cold forming machine or hydraulic pipe fittings machine is pivotal for any business aiming for excellence in the Special Equipment Manufacturing Industry and the broader Manufacturing of metal forming machine tools sector. These machines are not just equipment; they are catalysts for precision, efficiency, and material integrity, crucial for critical piping applications. Beijing Sinoworld Steel Material Co., Ltd. stands as a trusted partner, renowned for delivering durable, high-performance, and sustainable solutions that empower businesses to meet their production goals while adhering to the highest industry standards. Our commitment to innovation, quality, and customer satisfaction reinforces our reputation as a leader in specialized manufacturing equipment. Choose Beijing Sinoworld Steel Material Co., Ltd. to elevate your production capabilities and secure a competitive edge. Contact us today to learn how our advanced machinery can transform your operations.- Email: garvinliu@world-steelmaterial.com

- Visit our website: https://www.world-steelmaterial.com

Post time: Sep . 22, 2025 11:35