Precision Pipe Bending with hot forming elbow machine Technology

In the realm of B2B industrial manufacturing, the demand for high-integrity, high-performance pipe fittings is continuously escalating. Central to this demand is the hot forming elbow machine, a critical piece of equipment designed for the precise production of seamless elbows used across a multitude of heavy industries. This technology ensures the metallurgical integrity and dimensional accuracy essential for safe and efficient fluid and gas transportation systems. Our focus is on providing robust, efficient, and technologically advanced solutions that meet the stringent requirements of modern industrial applications, including those also utilizing hydraulic pipe fittings machine for diverse component manufacturing.

Industry Trends Shaping Pipe Fitting Manufacturing

The landscape of industrial pipe fitting manufacturing is experiencing significant transformation, driven by several key trends. Automation and intelligent control systems are becoming standard, enhancing precision, reducing human error, and increasing production efficiency. There's a growing emphasis on energy efficiency and sustainable manufacturing practices, prompting innovations in heating technologies and material utilization. Furthermore, the increasing complexity of projects in sectors like petrochemicals and nuclear power necessitates machines capable of handling a wider range of exotic materials and larger pipe dimensions with uncompromising quality. The integration of Industry 4.0 principles, including IoT and real-time data analytics, is optimizing operational performance and predictive maintenance for machinery like the hot forming elbow machine.

The demand for custom and small-batch production is also rising, requiring flexible machinery that can quickly adapt to varying specifications without extensive retooling. This agility is crucial for manufacturers to remain competitive and responsive to niche market requirements. Advancements in metallurgy also impact the types of materials that can be processed, pushing the boundaries of machine design for stronger, more corrosion-resistant alloys. This evolution ensures that technologies such as the hot forming elbow machine remain at the forefront of pipe fitting production.

Detailed Manufacturing Process Flow of a Hot Forming Elbow Machine

The production of elbows using a hot forming elbow machine is a sophisticated multi-stage process, ensuring the final product meets stringent quality and performance criteria. This process leverages controlled heating and forming techniques to achieve desired metallurgical properties and precise geometries.

Product Materials & Preparation:

- Materials: Typically, carbon steel (e.g., ASTM A234 WPB), stainless steel (e.g., ASTM A403 WP304/316), and various alloy steels (e.g., ASTM A234 WP11/22/91) are used. The choice depends on the application's specific requirements for pressure, temperature, and corrosion resistance.

- Cutting: Raw pipe material is cut to precise lengths, ensuring adequate material for the forming process and minimizing waste.

- Beveling: Pipe ends are often beveled at this stage to facilitate subsequent welding processes during final assembly.

Manufacturing Processes:

- Induction Heating: The prepared pipe section is uniformly heated in an induction coil. This heating must be precise, reaching specific temperatures (e.g., 900-1100°C for carbon steel) to achieve optimal malleability without compromising material integrity. The uniform heating prevents localized stress concentration during forming.

- Hot Forming (Mandrel Bending): The heated pipe is then pushed over a mandrel with a specific radius. Simultaneously, a forming die shapes the pipe into the desired elbow geometry. The controlled application of axial force and the temperature ensure a smooth, wrinkle-free bend. This process, also known as hot push-forming, is superior to cold forming for larger diameters and thicker walls due to its ability to maintain material integrity and reduce internal stresses.

- Calibration & Sizing: After initial forming, the elbow may undergo a calibration step to achieve final precise dimensions, including outer diameter, wall thickness, and bend radius. This stage fine-tunes the geometrical accuracy.

- Heat Treatment: Post-forming, the elbows undergo controlled heat treatment processes, such as normalizing, annealing, or quenching and tempering. This process relieves internal stresses induced during forming, refines grain structure, and restores or enhances mechanical properties (e.g., tensile strength, toughness, hardness).

- Surface Finishing & Cleaning: The elbows are cleaned to remove scale and impurities. This may involve shot blasting or pickling. Surface treatments ensure a smooth finish and prepare the product for coating or further processing.

- Machining (CNC): For specific applications requiring extremely tight tolerances or complex end preparations, CNC machining may be employed to achieve precise bevels, counterbores, or other features.

Testing Standards & Quality Assurance:

All manufactured elbows undergo rigorous testing to comply with international standards. Common testing standards include:

- ISO 9001: For Quality Management Systems.

- ASME B16.9 / ANSI B16.9: For Factory-Made Wrought Buttwelding Fittings.

- ASTM A234 / A403: Material specifications.

- NDE (Non-Destructive Examination): Includes Magnetic Particle Testing (MPT), Ultrasonic Testing (UT), Radiographic Testing (RT), and Dye Penetrant Testing (DPT) to detect surface and sub-surface flaws.

- Hydrostatic Testing: Although typically performed on the assembled piping system, material integrity often includes a pressure test simulation.

- Dimensional Inspection: Ensures conformity to specified dimensions and tolerances.

Service Life & Target Industries:

When properly manufactured and installed, elbows from a hot forming elbow machine can have a service life of several decades, often exceeding 20-30 years, especially in well-maintained systems. They are indispensable in:

- Petrochemical & Oil & Gas: For pipelines, refineries, and offshore platforms due to their ability to withstand high pressures and corrosive media.

- Power Generation: In steam lines, cooling systems, and power plant infrastructure.

- Water Supply & Drainage: For large-scale municipal and industrial water transfer systems.

- Shipbuilding: For marine piping systems requiring robust and corrosion-resistant components.

- Metallurgy: In industrial processing plants for material handling.

Key Advantages in Application Scenarios:

- Energy Saving: By producing seamless elbows, these machines eliminate the need for extensive welding joints, reducing energy consumption associated with post-weld heat treatment and quality checks.

- Corrosion Resistance: The hot forming process, followed by appropriate heat treatment, enhances the material's microstructure, improving its inherent resistance to corrosion, particularly for stainless and alloy steels, critical in aggressive chemical environments.

- Enhanced Structural Integrity: Unlike welded elbows, hot formed seamless elbows have a continuous grain flow, making them inherently stronger and more resistant to fatigue and stress corrosion cracking.

Technical Specifications and Parameters

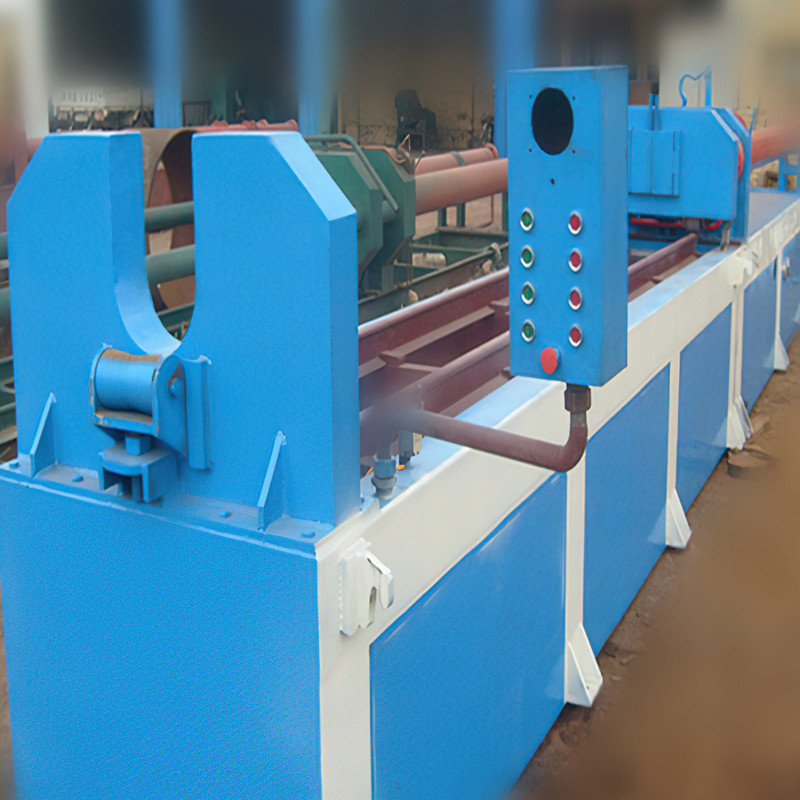

A high-performance hot forming elbow machine is characterized by its robust design and precise control systems, enabling the consistent production of high-quality fittings. Key technical parameters define its capabilities and efficiency.

| Parameter | Description/Value |

|---|---|

| Forming Capacity (OD) | DN150 - DN1200 (6 inch - 48 inch) |

| Wall Thickness Range | Sch.10 - Sch.160, XXS (5mm - 100mm) |

| Forming Material | Carbon Steel, Stainless Steel, Alloy Steel |

| Heating Method | Medium Frequency Induction Heating |

| Total Installed Power | 250 kW - 1500 kW (Varies by model and capacity) |

| Hydraulic System Pressure | 16 MPa - 25 MPa |

| Control System | PLC with HMI Touchscreen Interface |

| Product Standards | ASME B16.9, EN 10253, GOST 17375 |

| Operating Temperature | Ambient, Cooling water required for induction coil |

| Machine Dimensions (L x W x H) | Varies significantly by capacity (e.g., 10m x 3m x 2.5m for mid-range) |

These specifications underscore the precision and power required for industrial-scale elbow production. The integrated PLC control allows for repeatable processes, ensuring consistent quality and minimal material waste. This level of technical sophistication also extends to related machinery, such as hydraulic pipe fittings machine systems, which benefit from similar advanced control and power delivery mechanisms.

Application Scenarios and Industry Impact

The versatility and reliability of elbows produced by a hot forming elbow machine make them indispensable across a broad spectrum of critical industries. Their ability to handle diverse material types and dimensions ensures their suitability for demanding environments.

- Oil & Gas Exploration and Transportation: Essential for high-pressure pipelines, drilling rigs, and processing facilities where structural integrity under extreme conditions is paramount. The seamless nature of hot-formed elbows reduces leakage risks.

- Chemical and Petrochemical Plants: Used extensively in facilities handling corrosive chemicals, high temperatures, and volatile substances, where material compatibility and resistance to chemical degradation are critical.

- Power Generation (Thermal, Nuclear, Hydro): Crucial for steam lines, cooling water systems, and general process piping in power plants, where reliability and longevity are non-negotiable for continuous operation.

- Water and Wastewater Treatment: For large-diameter piping systems in municipal and industrial water infrastructure, requiring robust fittings that can withstand continuous flow and environmental exposure.

- Shipbuilding and Marine Applications: Provides durable and corrosion-resistant piping components for various marine systems, from propulsion to ballast, in harsh saltwater environments.

- Mining and Mineral Processing: Utilized in slurry pipelines and processing plants where pipes must endure abrasive materials and challenging operational conditions.

In each of these sectors, the operational continuity and safety heavily rely on the quality of pipe fittings. The hot forming process, by enhancing material properties and ensuring dimensional accuracy, directly contributes to reducing maintenance costs, preventing catastrophic failures, and extending the overall lifecycle of industrial infrastructure.

Technical Advantages of Hot Forming Technology

The use of a hot forming elbow machine offers distinct technical advantages over other pipe bending methods, particularly cold forming or fabricated (welded segment) elbows. These advantages are crucial for industries where performance and reliability are paramount.

- Superior Metallurgical Properties: Hot forming occurs above the recrystallization temperature of the metal. This process refines the grain structure, leading to improved tensile strength, toughness, and ductility. It also relieves internal stresses, making the material less susceptible to stress corrosion cracking and fatigue.

- Uniform Wall Thickness: Unlike cold bending, which can lead to thinning on the outer radius and thickening on the inner radius, hot forming allows for more controlled material flow, resulting in a more uniform wall thickness throughout the bend. This is critical for maintaining pressure ratings and structural integrity.

- Seamless Construction: Hot formed elbows are seamless, eliminating longitudinal welds that can be potential points of failure, especially in high-pressure or corrosive environments. This significantly reduces the risk of leaks and improves overall system reliability.

- High Dimensional Accuracy: Precise temperature control and sophisticated mandrel design ensure that the formed elbows consistently meet strict dimensional tolerances (e.g., bend radius, end-to-end dimensions, and squareness).

- Increased Production Efficiency: Automated hot forming machines can produce elbows at a higher rate with consistent quality compared to manual fabrication or less advanced bending techniques.

- Versatility in Materials and Sizes: This technology is capable of forming a wide range of materials, including difficult-to-form alloys, and accommodates a broad spectrum of pipe diameters and wall thicknesses, making it highly versatile for various industrial requirements.

These advantages collectively contribute to a longer service life, reduced maintenance, and enhanced safety in complex piping systems, making hot formed elbows the preferred choice for demanding applications where failure is not an option. The precision and automation capabilities are also a hallmark of advanced hydraulic pipe fittings machine technology, emphasizing a shared commitment to quality and efficiency.

Vendor Comparison and Selection Criteria

Selecting the right hot forming elbow machine vendor is a critical decision for any B2B entity. It involves evaluating not just the machine's specifications but also the vendor's reputation, support capabilities, and technological innovation. Here's a comparative overview based on key criteria:

| Criterion | Vendor A (e.g., World Steel Material) | Vendor B (Competitor 1) | Vendor C (Competitor 2) |

|---|---|---|---|

| Max Forming OD | DN1200 (48 inch) | DN1000 (40 inch) | DN800 (32 inch) |

| Automation Level | Full PLC & HMI, Robotic Loading Option | PLC Controlled, Manual Loading | Semi-Automatic |

| Heating Efficiency | High (Advanced Induction) | Medium-High (Standard Induction) | Medium (Resistance Heating) |

| Material Versatility | Excellent (CS, SS, Alloys, Exotics) | Good (CS, SS, some Alloys) | Basic (CS, SS) |

| After-Sales Support | Global Network, 24/7 Remote & On-site | Regional Support, Business Hours | Limited, Local Agents |

| Certifications | ISO 9001, CE, ASME | ISO 9001, CE | ISO 9001 |

| Lead Time (Standard Model) | 12-16 Weeks | 16-20 Weeks | 18-24 Weeks |

When evaluating vendors, it is crucial to consider total cost of ownership, including operational efficiency, maintenance, and potential downtime, rather than just the initial purchase price. A vendor with strong R&D, like World Steel Material, is more likely to offer advanced features that translate into long-term savings and superior product quality. We pride ourselves on offering comprehensive solutions that extend beyond the machine itself, ensuring seamless integration and optimized performance for your production line, similar to our commitment for hydraulic pipe fittings machine systems.

Customized Solutions for Unique Requirements

Recognizing that no two industrial operations are identical, we offer highly customized solutions for our hot forming elbow machine series. Our engineering team collaborates closely with clients to understand specific production needs, material types, target output, and integration challenges. Customization options include:

- Extended Diameter & Wall Thickness Ranges: Designing machines to accommodate pipes beyond standard specifications for specialized projects.

- Advanced Material Compatibility: Tailoring heating and forming parameters for ultra-high-strength alloys, duplex/super duplex stainless steels, or other exotic materials.

- Enhanced Automation Levels: Integrating robotic handling systems for loading, unloading, and part transfer to minimize manual intervention and increase safety in high-volume production.

- Specific Heating Frequencies: Optimizing induction heating systems for faster heat cycles or more precise temperature gradients, depending on material characteristics.

- Integrated Quality Control: Adding in-line NDE capabilities (e.g., eddy current, laser scanning) for real-time defect detection and dimensional verification.

- Data Logging & IIoT Integration: Customizing control systems for comprehensive data acquisition, remote monitoring, and integration with existing factory information systems (MES/ERP).

Our ability to deliver bespoke solutions ensures that clients receive a machine precisely tailored to maximize their operational efficiency and product quality, providing a competitive edge in their respective markets. This consultative approach is a cornerstone of our service philosophy.

Application Case Studies

Real-world application demonstrates the tangible benefits of our hot forming elbow machine technology.

Case Study 1: Large-Diameter Pipeline Project, Middle East

- Challenge: A major energy infrastructure developer required a reliable supply of DN900 (36 inch) carbon steel elbows (Sch. 80) for a new crude oil pipeline expansion. The client faced issues with inconsistent wall thickness and delayed delivery from previous suppliers using traditional bending methods.

- Solution: We deployed a high-capacity hot forming elbow machine with optimized induction heating. Our solution included automated material handling and real-time thickness monitoring.

- Results: The client achieved a 25% reduction in project lead time due to consistent, high-speed production. Wall thickness variations were reduced by 40% compared to industry average, leading to zero rejections based on dimensional tolerance. The superior metallurgical integrity of the elbows also contributed to an estimated 15% increase in the pipeline's projected service life.

Case Study 2: Stainless Steel Fittings for Pharmaceutical Processing, Europe

- Challenge: A pharmaceutical equipment manufacturer needed a consistent supply of small-to-medium diameter (DN50-DN200) 316L stainless steel elbows with ultra-smooth internal surfaces to prevent bacterial growth and comply with stringent hygienic standards. Cold bending often introduced internal surface imperfections and residual stresses.

- Solution: Our specialized hot forming elbow machine was configured with precise temperature control and a polished mandrel surface, followed by a passivation treatment.

- Results: The hot formed elbows demonstrated superior surface finish (Ra

Frequently Asked Questions (FAQ)

- Q1: What is the maximum wall thickness your hot forming elbow machine can process?

- A1: Our standard machines can typically handle wall thicknesses up to 100mm (XXS). For specific requirements, we offer customized solutions that can extend this range.

- Q2: What materials are compatible with your hot forming process?

- A2: Our machines are designed to process a wide range of materials, including carbon steel (e.g., A234 WPB), stainless steel (e.g., A403 WP304/316/321, Duplex, Super Duplex), and various alloy steels (e.g., A234 WP11/22/91). Material compatibility is a key strength of the hot forming method.

- Q3: How does hot forming compare to cold bending for producing elbows?

- A3: Hot forming is superior for larger diameters, thicker walls, and materials requiring enhanced metallurgical properties. It results in seamless elbows with uniform wall thickness, better grain structure, and reduced internal stresses, critical for high-pressure and corrosive applications. Cold bending is typically limited to smaller diameters and thinner walls, and may introduce undesirable stresses or wall thinning.

- Q4: What certifications do your machines and products hold?

- A4: Our manufacturing processes are certified under ISO 9001:2015 for quality management. Our machines comply with CE directives, and the produced elbows meet international standards such as ASME B16.9, EN 10253, and GOST 17375, among others.

Lead Time & Fulfillment Details

Our commitment to timely delivery is a cornerstone of our service. Standard configurations of the hot forming elbow machine typically have a lead time of 12-16 weeks from order confirmation to ex-works readiness. This period allows for meticulous manufacturing, assembly, and rigorous factory acceptance testing (FAT). For highly customized solutions, lead times may extend to 18-24 weeks, depending on the complexity of engineering and component sourcing. We provide detailed project timelines with clear milestones and regular progress updates. Shipping logistics, including crating, international freight, and customs documentation, are managed efficiently to ensure smooth delivery to your facility worldwide. Our experienced team assists with installation supervision and commissioning to bring your machine online swiftly.

Warranty Commitments

We stand behind the quality and reliability of our hot forming elbow machine systems. All machines come with a standard 12-month warranty from the date of commissioning or 18 months from shipment, whichever comes first. This warranty covers manufacturing defects in materials and workmanship. We also offer extended warranty programs tailored to client needs, providing additional peace of mind and protection for your investment. Our warranty terms are transparent, ensuring that clients understand the scope of coverage and the procedures for service requests.

Comprehensive Customer Support

Our relationship with clients extends far beyond the point of sale. We offer a robust suite of after-sales support services to ensure the continuous optimal performance of your hot forming elbow machine. This includes:

- Technical Support: 24/7 remote technical assistance via phone, email, and video conferencing. Our expert engineers are available to diagnose issues and provide guidance.

- On-site Service: Availability of field service engineers for on-site troubleshooting, maintenance, and repairs, minimizing downtime.

- Spare Parts Management: A comprehensive inventory of genuine spare parts, ensuring quick availability and delivery to prevent prolonged operational halts.

- Training Programs: Customizable training courses for your operators and maintenance staff, conducted either at our facility or yours, covering machine operation, programming, routine maintenance, and safety protocols.

- Preventative Maintenance Contracts: Offering scheduled maintenance visits to proactively identify and address potential issues, extending machine life and maintaining peak performance.

Our dedicated customer support ensures that your investment in a hot forming elbow machine yields maximum productivity and longevity, reflecting our commitment to client success.

Conclusion

The hot forming elbow machine stands as a cornerstone technology in the production of high-integrity pipe fittings, crucial for the demanding environments of modern industrial infrastructure. Its ability to produce seamless, metallurgically superior elbows with exceptional dimensional accuracy offers unparalleled advantages in terms of safety, reliability, and long-term operational efficiency. By embracing advanced automation, precision control, and robust engineering, our machines not only meet current industry standards but also anticipate future requirements, ensuring that clients are equipped with the best possible solutions for their manufacturing needs. Investing in this advanced technology, complemented by comprehensive support and customization capabilities, positions businesses for sustainable growth and a significant competitive edge.

References:

- ASTM International. (2022). "Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High-Temperature Service." ASTM A234/A234M.

- ASME. (2020). "Factory-Made Wrought Buttwelding Fittings." ASME B16.9.

- ISO 9001:2015. (2015). "Quality Management Systems – Requirements." International Organization for Standardization.

- Induction Heating Handbook. (2018). The Induction Heating Company.

- Journal of Materials Processing Technology. (Vol. 278, 2020). "Finite Element Analysis of Hot Forming Process for Large Diameter Elbows."

Post time: Sep . 13, 2025 11:20