Bulk Galvanized Pipe: insider notes from the field

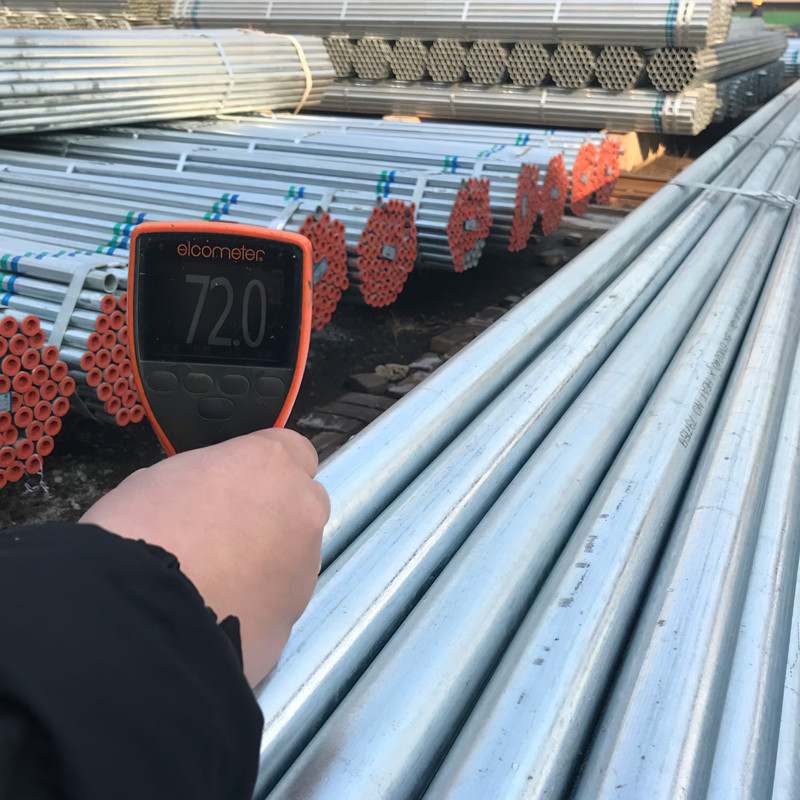

If you source Bulk Galvanized Pipe regularly, you already know the market’s been lively this year—zinc price ripples, stricter inspections, and buyers demanding clearer mill traceability. From Beijing’s Tongzhou District (Rm 1103, Shangpintaihu Bld 3#), this product line has been quietly gaining ground thanks to consistent coating weights and, frankly, responsive pre-shipment testing. I’ve walked enough yards to say: details matter.

Quick specs that actually help

| Item | Specification |

|---|---|

| Outside diameter | 1/2”–32” |

| Wall thickness | 2.77–33 mm |

| Length range | 5.8–12 m (custom cut available) |

| Standards | GB, ANSI, ASME, ASTM, JIS, DIN, BS, EN |

| Steel grades | Q195/Q215/Q235/Q345, 10#/20#, ASTM A106 Gr.B |

| Zinc mass | 170–550 g/㎡ (≈24–77 μm, real-world use may vary) |

| Ends & packaging | Plastic caps; bundled; plain/threaded/beveled |

| Coating method | Hot-dip galvanizing (HDG) |

Process flow, testing, and why it matters

Materials: coil/round billet in Q195–Q345 or 10#/20#/A106 Gr.B. Forming via ERW or seamless rolling. Then pickling, fluxing, hot-dip bath (~450℃), air knife control, quench/passivation, marking.

- Coating mass verification: ASTM A90/A90M gravimetric check.

- Adhesion: hammer bend or knife test per ISO 1461 guidance.

- Hydrostatic: ≥3.0 MPa, 5–10 s hold (project-specific).

- NDT: ultrasonic/eddy-current on weld seams for ERW.

Field performance: inland C3 environments can hit 30–50 years; coastal C5 it’s often 15–25 years unless you push ≥450 g/㎡ plus topcoat. Salt-spray (ASTM B117) results I’ve seen: 240–720 h to red rust depending on zinc mass—honestly, lab numbers aren’t the whole story, but they align with site outcomes when installation is careful and cuts are sealed.

Where it’s used (and why buyers stick with it)

- Municipal water, fire mains, and sprinkler headers (ASTM A53 + HDG finish).

- Fencing, greenhouse frames, solar racking, walkways and scaffolding.

- Cable conduit, compressor air lines, low-temp process lines.

- Agriculture: irrigation risers, cattle yards—“surprisingly forgiving,” as one rancher told me.

Advantages: corrosion resistance, predictable coating, easy welding (with proper prep), and—this is underrated—good resale value for surplus lots. Many customers say the stock consistency is the clincher.

Vendor snapshot (what I compare on my short list)

| Vendor | MOQ | Zinc mass | Certs | Lead time | Notes |

|---|---|---|---|---|---|

| World Steel Material | ≈20–25 t | 170–550 g/㎡ | ISO 9001/14001 | 10–20 days | Solid MTRs; consistent diameters |

| Regional Trader A | ≈10 t | 200–300 g/㎡ | Self-declared | Ready stock | Check actual coating test |

| Mill B (no stock) | ≈50 t | Up to 600 g/㎡ | ISO/CE | 30–45 days | Custom runs; longer lead |

Customization and real-world tweaks

- Cut-to-length; beveling; NPT/BSPT threading; grooving for fire systems.

- Higher zinc tiers for marine zones; passivation/sealant; paint-over (duplex) systems.

- Perforations for fencing/irrigation; tighter OD tolerances for slip-fit structures.

Case study: a coastal greenhouse retrofit used Bulk Galvanized Pipe at 450 g/㎡ with duplex paint on joints. After 18 months by the shore—zero red rust, only faint white bloom on unpainted cut ends. The site manager said, “installation-time sealing was the difference,” and I’d agree.

Final take

If your bid hinges on lifecycle cost, Bulk Galvanized Pipe with ≥350 g/㎡ zinc is a safe baseline for urban infrastructure, and ≥450 g/㎡ for coastal or chemical-adjacent yards. To be honest, I’d always budget a bit for joint sealing and touch-up per ISO 1461 and ASTM A780—cheap insurance.

References

- ASTM A123/A123M: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

- ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods.

- ASTM A53/A53M: Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless.

- EN 10240: Internal and/or external protective coatings for steel tubes — Hot dip galvanizing.

- ASTM A90/A90M: Test Method for Weight [Mass] of Coating on Iron and Steel Articles with Zinc.

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus.

Post time: Nov . 06, 2025 17:30