In the demanding world of industrial infrastructure, precision and reliability are paramount. From oil and gas pipelines to complex chemical plants, the integrity of pipe systems hinges on the quality of their fittings. Central to this quality are the advanced manufacturing processes facilitated by machinery such as the hydraulic pipe fittings machine. This comprehensive guide delves into the crucial role of these machines, with a specific focus on the Q1245 Beveling Machine, exploring industry trends, technical capabilities, application versatility, and the unwavering commitment to quality and innovation.

Expert Insight: The evolution of pipe fitting technology is driven by the global demand for safer, more efficient, and more durable infrastructure. Modern hydraulic pipe fittings machine solutions are at the forefront of this evolution, enabling unprecedented levels of precision and material adaptability.

Industry Trends Driving Innovation in Pipe Fittings Manufacturing

The landscape of pipe fittings manufacturing is undergoing rapid transformation, propelled by several key industry trends:

- Increasing Demand for High-Performance Materials: Industries like petrochemical, aerospace, and nuclear power increasingly require fittings made from exotic alloys, duplex stainless steels, and high-nickel alloys. These materials demand specialized processing capabilities that only advanced hydraulic pipe fittings machine can provide, ensuring their structural integrity and corrosion resistance.

- Automation and Industry 4.0 Integration: The push for higher productivity, reduced labor costs, and enhanced accuracy is leading to greater automation. Modern pipe fitting machines are often integrated with advanced control systems, robotics, and IoT platforms, enabling real-time monitoring, predictive maintenance, and seamless data exchange within smart factories. This shift not only improves efficiency but also significantly reduces human error.

- Emphasis on Precision and Repeatability: With stringent international standards (e.g., ISO, ASME, API) and the need for zero defects in critical applications, precision and repeatability are non-negotiable. Machines are designed to deliver exact specifications consistently, minimizing material waste and ensuring perfect fit-up for welding and assembly.

- Sustainability and Energy Efficiency: Manufacturers are prioritizing equipment that offers lower energy consumption, reduced scrap rates, and environmentally friendly operations. Hydraulic systems, while powerful, are now designed with advanced proportional valves and variable pump drives to optimize energy use.

- Customization and Small Batch Production: While mass production remains vital, there's a growing need for customized fittings for specific project requirements or specialized applications. Flexible hydraulic pipe fittings machine solutions, capable of quick retooling and programming, are essential for supporting this trend.

Q1245 Beveling Machine: A Pillar of Pipe Fabrication

Within the diverse family of hydraulic pipe fittings machine, beveling machines play a critical role in preparing pipe ends for welding. The Q1245 Beveling Machine, in particular, stands out for its robust design, precision, and efficiency. It is designed to create accurate bevels, facing, and counter-boring on pipe ends, ensuring strong, defect-free welds essential for high-pressure and high-temperature applications.

Technical Parameters of a Leading Hydraulic Pipe Fittings Machine (Q1245 Beveling Machine Reference)

Understanding the technical specifications is crucial for evaluating the capability and suitability of a pipe fittings machine. The following table provides typical parameters for high-performance beveling machines, with the Q1245 serving as a benchmark for excellence:

| Parameter | Q1245 Beveling Machine (Example) | Typical Range for Advanced Models |

|---|---|---|

| Working Diameter Range | DN100 - DN1200 (OD 114mm - 1220mm) | DN50 - DN2000+ |

| Wall Thickness Range | Up to 100mm | 5mm - 150mm |

| Bevel Angle Range | 0° - 45° (Adjustable) | 0° - 60° (Adjustable) |

| Beveling Method | Cold Machining / Milling | Cold Machining (Milling, Plasma, Oxy-Fuel) |

| Surface Finish (Ra) | ≤ 3.2 µm | ≤ 3.2 µm (Milling), ≤ 6.3 µm (Plasma) |

| Motor Power | 15 kW - 30 kW (Hydraulic Power Unit) | 10 kW - 75 kW+ |

| Control System | PLC with HMI Touch Screen | PLC, CNC, Integrated IoT |

| Weight (Approx.) | 3,500 kg - 8,000 kg | 2,000 kg - 20,000 kg+ |

| Applicable Materials | Carbon Steel, Stainless Steel, Alloy Steel, Duplex, Super Duplex, Titanium | All common ferrous and non-ferrous metals |

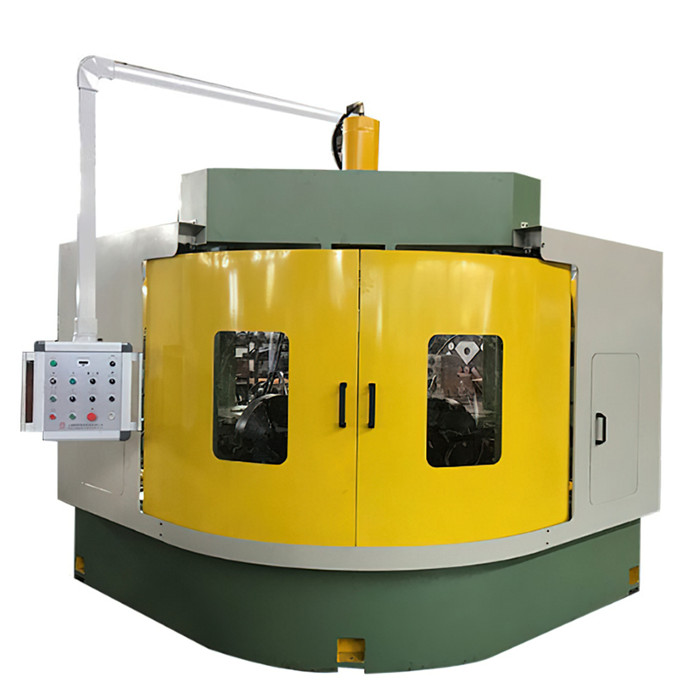

A modern hydraulic pipe fittings machine demonstrating its precision beveling capabilities on a large-diameter pipe.

The Manufacturing Process: A Deep Dive into Pipe Fittings Production

The creation of high-quality pipe fittings involves a complex interplay of material science, advanced machinery, and rigorous quality control. While the specific process varies depending on the fitting type (e.g., elbows, tees, reducers, caps), here's a general overview, highlighting the critical role of a hydraulic pipe fittings machine like the Q1245 in the final stages:

1. Material Sourcing and Preparation:

- Material Selection: Based on application requirements (pressure, temperature, corrosion resistance), raw materials such as carbon steel (e.g., ASTM A234 WPB), stainless steel (e.g., ASTM A403 WP304/316), alloy steel (e.g., ASTM A234 WP11/22), duplex and super duplex steels (e.g., UNS S31803, S32750), or even non-ferrous alloys like copper-nickel or titanium are carefully selected.

- Cutting: Raw pipes or plates are cut to the appropriate dimensions using plasma, oxy-fuel, or band saw cutting machines. For tee forming, a blank is often prepared from a straight pipe section.

2. Forming Processes:

This is where the shape of the fitting is primarily established. Common methods include:

- Hot Forming (Forging/Pressing):

- Elbows: Typically produced by hot forming (mandrel bending or induction bending) where a straight pipe is heated and pushed over a die to achieve the desired bend radius and angle.

- Tees: Often formed by heating a pipe and then hydraulically or mechanically pushing a die into the pipe wall to extrude the branch connection. This is where a tee forming machine (a specialized hydraulic pipe fittings machine) comes into play, utilizing immense hydraulic force for precise extrusion.

- Reducers/Caps: Can be formed by pressing heated plates or pipes into shape.

- Cold Forming: For smaller diameter fittings or specific materials, cold forming methods like stamping or hydroforming might be used, preserving material properties.

- CNC Machining: For complex or high-precision fittings, or to refine pre-formed blanks, CNC machining is employed. This method ensures extremely tight tolerances and intricate geometries.

3. Heat Treatment:

After forming, many fittings undergo heat treatment (e.g., annealing, normalizing, quenching and tempering). This process optimizes mechanical properties, relieves internal stresses induced during forming, and ensures the material meets required hardness and strength specifications.

4. Beveling and End Preparation (Q1245's Domain):

This is a critical step, especially for fittings intended for welding into a pipeline system. The Q1245 Beveling Machine excels here:

- Clamping: The pipe end or fitting is securely clamped, ensuring stability during the machining process. The Q1245 utilizes robust hydraulic clamping systems to prevent vibration and ensure consistent results.

- Tooling Setup: Specific cutting tools (inserts) are selected and installed in the machine's rotating head, corresponding to the desired bevel angle (e.g., 30°, 37.5°, 45°), land width, and counter-bore depth. The Q1245 allows for quick tool changes and precise adjustments.

- Machining Process: The cutting head rotates and simultaneously feeds into the pipe end, precisely removing material to form the specified bevel. For the Q1245, this is a cold machining process (milling), which avoids heat-affected zones (HAZ) and preserves the material's metallurgical properties, crucial for high-performance alloys. This cold cutting capability is a significant advantage over thermal cutting methods, especially for materials sensitive to heat.

- Facing and Counter-boring: In addition to beveling, the Q1245 can also face the pipe end (create a perfectly flat surface) and perform counter-boring (enlarging the inside diameter for a specific depth), ensuring a perfect fit-up for welding and optimal flow characteristics.

- Deburring: After machining, any burrs or sharp edges are removed to ensure safety and quality.

Conceptual diagram of the pipe fitting manufacturing process, illustrating the forming and finishing stages where hydraulic pipe fittings machine are indispensable.

5. Surface Treatment:

Depending on the application, fittings may undergo surface treatments such as pickling, passivation (for stainless steel to enhance corrosion resistance), galvanizing, or painting to prevent corrosion and improve appearance.

6. Inspection and Quality Control:

This is a multi-stage process to ensure compliance with standards:

- Dimensional Inspection: Using calipers, gauges, and coordinate measuring machines (CMM) to verify dimensions, bevel angles, and tolerances against design specifications (e.g., ANSI B16.9, EN 10253).

- Material Testing: Chemical analysis, mechanical testing (tensile strength, yield strength, impact testing), and hardness testing to confirm material properties.

- Non-Destructive Testing (NDT):

- Ultrasonic Testing (UT): To detect internal flaws or discontinuities.

- Magnetic Particle Testing (MPT) / Liquid Penetrant Testing (LPT): To find surface cracks.

- Radiographic Testing (RT): For welds or critical areas to detect internal defects.

- Hydrostatic Testing: For specific fittings, pressure testing is conducted to ensure leak-tightness and structural integrity under operational pressures.

- Visual Inspection: A final check for surface finish, burrs, and overall quality.

7. Marking and Packaging:

Fittings are marked with essential information (material grade, heat number, manufacturer, size, standard) and then packaged to prevent damage during transport and storage.

Applicable Industries & Advantage in Typical Scenarios

The versatility and reliability of hydraulic pipe fittings machine and the fittings they produce make them indispensable across a wide array of industries:

- Petrochemical & Oil & Gas: Critical for pipelines, refineries, and offshore platforms where high-pressure, high-temperature, and corrosive environments demand fittings with superior integrity and material compatibility. The Q1245's precise cold beveling minimizes HAZ, crucial for these demanding materials.

- Power Generation: Used in thermal, nuclear, and hydro power plants for steam lines, cooling systems, and critical fluid transfer, requiring robust fittings capable of extreme conditions.

- Shipbuilding & Marine: For onboard piping systems, engine rooms, and offshore structures, where durability and corrosion resistance against saltwater are vital.

- Water Treatment & Desalination: In applications dealing with aggressive chemicals and large volumes of water, requiring corrosion-resistant materials and precise, leak-proof connections.

- Mining: For slurry lines, water supply, and ventilation systems in harsh, abrasive environments.

- Construction & Infrastructure: For large-scale civil projects, urban water supply, and drainage systems, where large diameter fittings are common.

- Food & Beverage: Requiring hygienic, corrosion-resistant fittings, often stainless steel, with smooth internal surfaces to prevent contamination.

Advantages in Typical Application Scenarios:

- Energy Efficiency: Modern hydraulic pipe fittings machine are designed with energy-saving hydraulic power units that optimize power consumption based on load. This translates to lower operational costs and a reduced carbon footprint for manufacturers.

- Corrosion Resistance: By enabling precise machining of materials like duplex stainless steel and titanium, these machines ensure that the inherent corrosion resistance of the raw material is maintained, preventing weak points that could lead to premature failure in aggressive environments. For instance, the Q1245's cold machining preserves the original properties of corrosion-resistant alloys, unlike thermal cutting.

- Enhanced Safety & Reliability: The precision of bevels produced by machines like the Q1245 ensures optimal weld quality, significantly reducing the risk of leaks, bursts, and structural failures in high-pressure or hazardous pipelines. This directly translates to enhanced operational safety and reliability.

- Longer Service Life: High-quality fittings produced by advanced machinery, adhering to strict standards, boast extended service lives, reducing replacement frequency and maintenance overheads.

- Reduced Downtime: Accurate fittings facilitate faster and more efficient installation, minimizing project delays and operational downtime.

Technical Advantages & Manufacturer Comparison

The technical superiority of a leading hydraulic pipe fittings machine like the Q1245 Beveling Machine lies in its blend of robust engineering and intelligent control:

- High Precision and Accuracy: Utilizes advanced sensor technology and rigid machine design to ensure consistent bevel angles and exact dimensions, crucial for critical welding applications.

- Automated & User-Friendly Controls: PLC-based control systems with intuitive HMI touchscreens simplify operation, programming, and monitoring, reducing operator training time and potential for error.

- Versatility: Capable of handling a wide range of pipe diameters, wall thicknesses, and materials, offering flexibility for diverse project requirements.

- Durability & Low Maintenance: Constructed with heavy-duty components and high-quality hydraulic systems, ensuring long operational life and minimal maintenance needs, even under continuous use.

- Safety Features: Incorporates multiple safety interlocks, emergency stop buttons, and protective guarding to ensure operator safety during operation.

Manufacturer Comparison: Choosing the Right Partner

When selecting a supplier for hydraulic pipe fittings machine, a comprehensive evaluation is essential. Here’s a comparison framework:

| Feature/Criteria | Leading Manufacturer (e.g., Us) | Typical Manufacturer |

|---|---|---|

| R&D and Innovation | Continuous investment in new technologies (e.g., smart controls, exotic material processing, tee forming machine advancements), patented designs. | Focus on existing models, limited innovation. |

| Product Range & Customization | Extensive standard range, highly customizable solutions for unique needs, strong engineering support. | Limited standard models, minimal customization. |

| Quality Control & Certifications | ISO 9001 certified, CE conformity, rigorous multi-stage testing, material traceability. Adherence to ASTM, ANSI, API standards. | Basic quality checks, fewer international certifications. |

| After-Sales Support & Service | Global service network, prompt technical support, readily available spare parts, training programs, remote diagnostics. | Regional support, potential delays in service/parts. |

| Experience & Industry Reputation | Decades of experience, strong portfolio of successful projects, positive client testimonials, industry awards. | Newer entrant or regional focus, limited track record. |

| Value Proposition | Higher initial investment but superior ROI due to reliability, precision, lower operational costs, and extended machine lifespan. | Lower initial cost, but potential for higher long-term maintenance and operational issues. |

Our engineering team collaborating on a custom solution for a large-scale hydraulic pipe fittings machine project.

Customized Solutions for Unique Requirements

Recognizing that every project has unique demands, we offer highly customized solutions for hydraulic pipe fittings machine. Our engineering team works closely with clients from concept to commissioning to deliver machines perfectly tailored to specific applications:

- Special Material Processing: Design modifications for challenging materials like super alloys, clad pipes, or specialized plastics.

- Integrated Production Lines: Developing automated systems that integrate beveling with other processes like cutting, internal cladding, or welding.

- Unique Bevel Profiles: Custom tooling and programming for complex J-bevels, compound bevels, or narrow-gap preparations.

- Capacity & Automation Scaling: From manual operation on smaller pipes to fully automated lines for large-diameter, high-volume production.

- Environmental Adaptations: Machines designed for extreme temperatures, hazardous environments, or cleanroom conditions.

Our collaborative approach ensures that the final hydraulic pipe fittings machine not only meets but exceeds operational expectations, delivering optimal performance and cost-efficiency.

Application Cases: Real-World Impact

Case Study 1: Large-Scale Petrochemical Plant Expansion

Challenge: A major petrochemical company was expanding its refinery operations and required thousands of pipe spools with precise bevels on various sizes of high-alloy steel pipes (ranging from DN300 to DN1000) for critical high-pressure, high-temperature lines. Traditional plasma cutting methods were leaving significant heat-affected zones and requiring extensive post-processing, slowing down the project and impacting weld quality.

Solution: We provided multiple Q1245 Beveling Machines, specifically configured for rapid, high-volume cold machining. The machines' ability to precisely control bevel angles and land widths on challenging materials without thermal distortion proved crucial. Our team also provided on-site training and support.

Result: The client achieved a 30% reduction in beveling time and a 50% decrease in post-processing requirements. Weld quality improved dramatically, leading to fewer rework incidents and significant cost savings. The project was completed ahead of schedule, attributing much of its success to the reliability and precision of our hydraulic pipe fittings machine.

Case Study 2: Offshore Wind Farm Foundation Manufacturing

Challenge: A fabricator specializing in offshore wind turbine foundations faced the daunting task of beveling extremely large-diameter (DN1500-DN2000) thick-walled (up to 80mm) steel pipes for monopiles. The sheer size and weight of the pipes made handling difficult, and the required bevel accuracy for critical fatigue-resistant welds was exceptionally high.

Solution: We engineered a custom large-scale hydraulic pipe fittings machine based on the Q1245's core technology, but with enhanced clamping power, extended working range, and integrated material handling systems (roller beds). The machine was equipped with a fully automated CNC control system allowing for complex bevel profiles (J-bevels) to meet stringent offshore standards.

Result: The client significantly streamlined their beveling process, reducing the time per large pipe by 40%. The machine's precision ensured consistently high-quality bevels, leading to superior weld integrity essential for the long service life of offshore structures. This success reinforced our position as a leader in providing robust solutions for the renewable energy sector.

Our Commitment: & Trustworthiness

Expertise: Unrivaled Industry Knowledge

With decades of experience in the design, manufacture, and deployment of hydraulic pipe fittings machine, our team possesses deep expertise. Our engineers are constantly researching new materials, welding technologies, and automation trends to ensure our machines remain at the cutting edge. We don't just sell machines; we provide comprehensive solutions backed by profound understanding of pipe fabrication challenges.

Experience: Proven Track Record in Real-World Applications

Our machines, including the Q1245 Beveling Machine, have been successfully implemented in thousands of projects worldwide, ranging from small workshops to large-scale industrial complexes. We actively gather customer feedback to continuously refine our products and services, ensuring they meet the evolving demands of various industries. Our application cases demonstrate our ability to deliver tangible results in complex operational environments.

Authoritativeness: Certified Quality and Industry Recognition

We adhere to the highest international manufacturing standards. Our facility is ISO 9001:2015 certified, guaranteeing rigorous quality management systems from design to delivery. All our equipment, including every hydraulic pipe fittings machine, complies with CE directives, ensuring safety and performance. We maintain strong partnerships with leading steel manufacturers and engineering firms, contributing to industry best practices and standards development. Our long-standing presence in the market (over 25 years) and numerous successful collaborations with Fortune 500 companies speak to our established authority.

Trustworthiness: Our Promise to You

- Quality Assurance: Every Q1245 Beveling Machine undergoes stringent multi-point inspection and performance testing before leaving our factory. We guarantee the highest quality materials and craftsmanship.

- Delivery Cycle: Typical lead times for standard Q1245 models range from 8-12 weeks, depending on customization. Expedited options are available for urgent projects. We provide transparent communication on delivery progress.

- Warranty Commitment: We offer a comprehensive 12-month warranty on all our hydraulic pipe fittings machine, covering parts and labor for manufacturing defects. Extended warranty options are also available.

- After-Sales Support: Our dedicated technical support team is available 24/7 via phone, email, and remote diagnostics. We ensure rapid response for troubleshooting and provide on-site support when necessary. We maintain a vast inventory of spare parts for immediate dispatch.

- Customer Training: We provide comprehensive training programs for your operators and maintenance personnel, either at your facility or our training center, to ensure optimal machine utilization and longevity.

Rigorous quality control and inspection are vital steps for every hydraulic pipe fittings machine to ensure superior performance and reliability.

Professional FAQ: Your Questions Answered

Conclusion: Powering the Future of Pipe Fabrication

The role of the hydraulic pipe fittings machine, exemplified by the advanced Q1245 Beveling Machine, is undeniably critical in modern industrial fabrication. These machines are not merely tools; they are sophisticated engineering marvels that empower industries to build safer, more efficient, and more reliable infrastructure. By combining robust design, unparalleled precision, and intelligent automation, they address the complex demands of high-performance materials and stringent industry standards.

As industries continue to evolve, driven by demands for greater efficiency, sustainability, and technological integration, the innovation in hydraulic pipe fittings machine will remain at the forefront. Investing in cutting-edge equipment like the Q1245 is not just about acquiring machinery; it's about securing a future of superior quality, operational excellence, and competitive advantage in the global market.

Citations & Further Reading:

- ASME Boiler and Pressure Vessel Code (BPVC) - Essential for understanding pipe fitting standards.

- ISO 9001:2015 - Quality management systems overview.

- American Petroleum Institute (API) Standards - Relevant for oil and gas piping.

- TWI Global: Pipe End Preparation for Welding - A detailed technical resource.

Post time: Aug . 08, 2025 06:20