Hydraulic Pipe Fittings Machine is a key solution in the manufacturing industry, specifically within Special Equipment Manufacturing Industry and Manufacturing of metal processing machinery. This article explores how Beijing Sinoworld Steel Material Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Hydraulic Pipe Fittings Machine Overview

- Benefits & Use Cases of Hydraulic Pipe Fittings Machine in Manufacturing of metal processing machinery

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Hydraulic Pipe Fittings Machine from Beijing Sinoworld Steel Material Co., Ltd.

Hydraulic Pipe Fittings Machine Overview

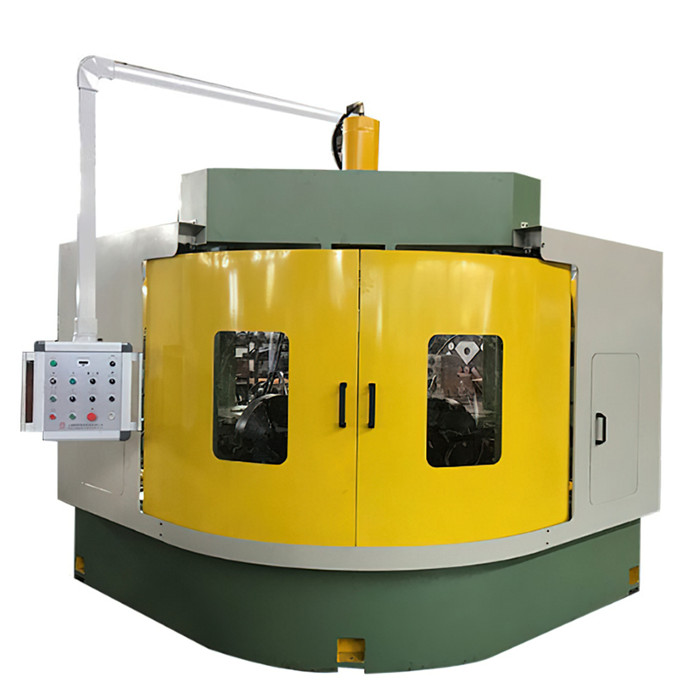

A Hydraulic Pipe Fittings Machine is purpose-built to form, bevel, expand, reduce, and prepare pipe ends and fittings with high repeatability under hydraulic power. In the Manufacturing of metal processing machinery, these systems are indispensable for fabricating elbows, reducers, tees, sockets, and couplings that must meet stringent dimensional and weld-prep tolerances. From pressure vessels to pipeline spools, the machines ensure consistent geometry, smooth bevels, and optimal surface finish that downstream welding cells rely on to hit first-pass yields. Beijing Sinoworld Steel Material Co., Ltd. supplies robust equipment such as its Q1245 beveling machine, integrating stable hydraulic actuation with precision tooling to deliver clean, uniform bevels and consistent end prep. For buyers evaluating a tee forming machine or comprehensive fittings line, Sinoworld’s engineering support helps match hydraulic capacity, tooling configuration, and control logic to your diameter ranges, materials, and takt time. Typical setups can be configured for carbon steel, stainless steel, and alloy pipes, and can be paired with automated loading/unloading to boost throughput. The result is a production cell that reduces rework, shortens cycle time, and improves weldability across high-mix or high-volume operations.

Benefits & Use Cases of Hydraulic Pipe Fittings Machine in Manufacturing of metal processing machinery

Across fabrication lines serving oil and gas, HVAC, shipbuilding, and energy infrastructure, a Hydraulic Pipe Fittings Machine streamlines critical steps: precision beveling for root pass integrity, expanding/reducing for tight tolerances, and tee forming for branch connections. In automated cells, hydraulic drives and servo-assisted controls maintain stable force and feed rates, improving surface quality and reducing heat-affected deformation. Compared with manual prep or ad hoc fixtures, users gain measurable advantages—shorter changeovers with quick-change tooling, higher repeatability that stabilizes OEE, and fewer nonconformities. Beijing Sinoworld Steel Material Co., Ltd. brings sector-specific know-how, advising on tooling geometries for specific schedules, integrating clamping systems for thin-wall tubes, and synchronizing hydraulic pressure profiles with CNC logic. The company’s beveling solutions are especially effective where consistent land and angle are critical to robotic welding parameters. When paired with upstream cutting and downstream welding cells, Sinoworld equipment helps create a closed-loop flow—from cut to bevel to fit-up—cutting bottlenecks and removing variability that often inflates labor and scrap. For plants seeking to upgrade legacy fixtures or add a tee forming machine workcell, Sinoworld’s application team supports feasibility trials, tooling selection, and on-site commissioning for faster ramp-up.

Cost, Maintenance & User Experience

Total cost of ownership for a Hydraulic Pipe Fittings Machine hinges on throughput gains, scrap reduction, and tooling longevity. By delivering uniform bevels and accurate forming, plants typically see fewer fit-up issues, fewer weld repairs, and shorter cycle times—key drivers of ROI in capital equipment approval. Durable hydraulic modules, rigid frames, and quality seals help maintain accuracy over long duty cycles. Preventive maintenance is straightforward: monitor hydraulic oil condition, keep filtration within spec, inspect seals and hoses, and track tooling wear with scheduled changeouts. Users report smoother onboarding when operators receive targeted training on clamping, feed settings, and tool geometry selection. Beijing Sinoworld Steel Material Co., Ltd. supports this with clear documentation, remote guidance, and optional on-site services. For B2B decision makers, the economics extend beyond purchase price—consider the reduced rework costs, stable takt, and improved first-pass yield that positively affect OEE. With proper care, a beveling or tee forming workcell integrates cleanly into existing lines, supporting continuous operation and predictable maintenance windows, while ensuring quality data capture for audits and customer compliance.

Sustainability & Market Trends in manufacturing

Industrial buyers increasingly evaluate equipment through a sustainability lens. Modern Hydraulic Pipe Fittings Machines support lower energy consumption with efficient hydraulic power units, pressure-on-demand control, and optimized feed rates that avoid overuse of power and tooling. Cleaner, consistent bevels also reduce grinding and post-processing, cutting abrasive consumption and airborne particulates. Compliance with quality and environmental systems—such as ISO-aligned documentation, traceability, and responsible oil handling—has become a standard expectation in the Special Equipment Manufacturing Industry. Beijing Sinoworld Steel Material Co., Ltd. aligns with these trends by emphasizing robust, leak-minimized hydraulic designs, well-documented maintenance practices, and options for digital monitoring that support predictive maintenance and lower waste. As manufacturers digitize, integrating sensors and data capture from beveling and tee forming operations enables better process control and sustainability reporting. Market demand for higher-integrity pipelines, pressure parts, and energy systems will continue to rise, and companies that standardize on reliable, efficient pipe fittings machinery are positioned to meet growth while hitting ESG targets and reducing lifecycle operating costs.

Conclusion on Hydraulic Pipe Fittings Machine from Beijing Sinoworld Steel Material Co., Ltd.

For operations in Manufacturing of metal processing machinery, a Hydraulic Pipe Fittings Machine is a practical path to stable quality, faster cycles, and lower rework. Beijing Sinoworld Steel Material Co., Ltd. combines durable construction, precise hydraulic control, and application support to help you standardize weld prep and forming—from beveling to tee forming—across your product mix. Partnering with a proven supplier simplifies commissioning, training, and long-term maintenance while safeguarding OEE. Contact us: email: garvinliu@world-steelmaterial.com. Visit our website: https://www.world-steelmaterial.com

Post time: Nov . 13, 2025 08:55