Introduction to Advanced Anti-Corrosion Pipe Solutions

In industrial operations, the integrity and longevity of piping systems are paramount. Corrosion, a ubiquitous threat, can lead to catastrophic failures, environmental damage, and substantial financial losses. To mitigate these risks, the application of advanced anti-corrosion solutions for piping systems has become indispensable. This article delves into the critical aspects of anti corrosion pipe, focusing on advanced coating technologies such as 3LPE, 3LPP, and FBE, which are essential for protecting vital infrastructure across diverse sectors.

Understanding the technical specifications, application scenarios, and the robust manufacturing processes behind these protective systems is crucial for B2B decision-makers and engineers. We will explore industry trends, offer detailed technical insights, present compelling application case studies, and provide a framework for evaluating vendor capabilities, ensuring a comprehensive understanding of these vital components in modern industrial design.

Industry Trends and Market Dynamics in Anti-Corrosion Solutions

The global market for anti-corrosion solutions, particularly for piping infrastructure, is experiencing sustained growth driven by increasing demand in energy, petrochemical, water treatment, and construction sectors. Key trends include the rising adoption of multi-layer coating systems, advancements in material science, and stringent regulatory requirements for environmental protection and operational safety. There's a notable shift towards more durable, long-lasting, and environmentally friendly coating options, moving away from conventional, less efficient methods.

One significant trend is the expansion of `[anti corrosion pipe coating]` for extreme environments, including deep-sea oil and gas exploration and geothermal energy projects. This necessitates coatings that can withstand high temperatures, pressures, and aggressive chemical exposure. Furthermore, the integration of smart coating technologies, offering real-time monitoring of coating integrity and corrosion detection, is on the horizon, promising a paradigm shift in maintenance strategies. The market is also seeing increased demand for customized solutions that cater to specific project requirements, underscoring the importance of versatile manufacturing capabilities and technical expertise among suppliers.

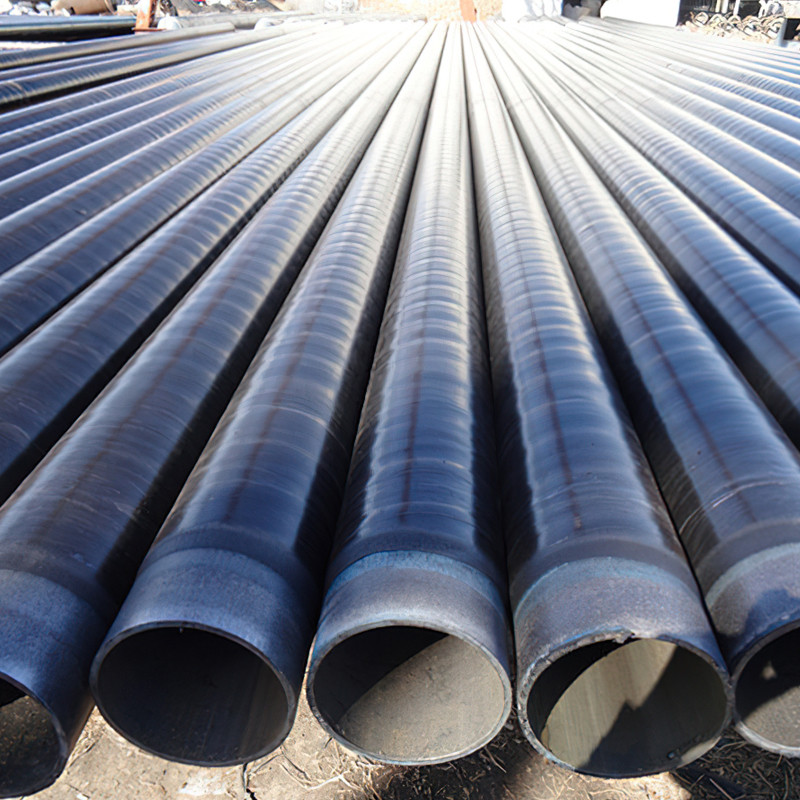

Detailed Manufacturing Process of Anti-Corrosion Pipe (3LPE/PP/FBE)

The manufacturing of high-performance `[anti corrosion steel pipe]` involves a sophisticated process designed to ensure maximum protection and longevity. The primary methods discussed here are 3-Layer Polyethylene (3LPE), 3-Layer Polypropylene (3LPP), and Fusion Bonded Epoxy (FBE), each offering distinct advantages.

1. Surface Preparation (Foundation of Protection)

- Inspection: Raw `[anti corrosion pipe]` is first inspected for any defects, ensuring it meets base material specifications.

- Blast Cleaning (NACE No. 1/SSPC-SP 5 White Metal Blast): Pipes undergo abrasive blast cleaning to achieve a near-white metal finish, removing rust, mill scale, and other contaminants. This process creates a rough surface profile (typically 50-100 microns) essential for mechanical adhesion of the coating.

- Dust Removal: After blasting, the pipe surface is meticulously cleaned using brushes or compressed air to remove all dust particles.

2. Pre-heating

- Pipes are pre-heated to a specific temperature (e.g., 200-250°C for FBE, slightly higher for 3LPE/3LPP) to ensure proper curing and adhesion of the coating materials. Induction heating is a common method for precise temperature control.

3. Coating Application (Key Process Variations)

FBE (Fusion Bonded Epoxy) Coating:

- Application: Dry epoxy powder is electrostatically applied onto the hot `[anti corrosion pipe]` surface. The heat causes the powder to melt, flow, and cure, forming a uniform, protective layer that is chemically bonded to the steel.

- Curing: The pipe passes through a curing oven to ensure complete cross-linking of the epoxy resin.

3LPE (3-Layer Polyethylene) / 3LPP (3-Layer Polypropylene) Coating:

- Layer 1 (FBE): Similar to the standalone FBE process, an FBE layer is applied first to provide excellent adhesion to the steel and primary corrosion protection.

- Layer 2 (Adhesive Copolymer): While the FBE is still hot, an adhesive layer, typically an extruded copolymer, is applied. This layer acts as a chemical bond between the FBE and the outer polyolefin layer.

- Layer 3 (Polyethylene/Polypropylene): The final layer of extruded polyethylene (for 3LPE) or polypropylene (for 3LPP) is applied over the adhesive. This layer provides robust mechanical protection, UV resistance, and excellent electrical insulation.

4. Cooling and Curing

- After coating, pipes are cooled, typically by a water quench, to solidify the coating and optimize its physical properties.

5. Quality Control and Testing Standards

- Holiday Detection (ASTM G62): Every coated pipe undergoes holiday detection using a high-voltage spark tester to identify any pinholes or discontinuities in the coating.

- Adhesion Testing (ASTM D3359): Cross-hatch or peel tests are performed to verify the bond strength between the coating and the steel substrate.

- Thickness Measurement (ISO 2808): Coating thickness is measured using non-destructive methods to ensure it meets specified requirements.

- Impact Resistance (ASTM G14): Samples are tested for impact resistance to simulate potential damage during handling and installation.

- Cathodic Disbondment (ASTM G8): Evaluates the coating's ability to resist disbondment when subjected to cathodic protection currents, a critical parameter for buried pipelines.

- Flexibility Testing (ASTM D522): Determines the coating's resistance to cracking when bent, important for pipelines that may experience movement.

Service Life & Target Industries: These coatings typically offer a service life exceeding 30-50 years, significantly reducing maintenance costs and downtime. Target industries include: petrochemical, oil and gas (onshore and offshore), water supply & drainage, mining, power generation, and chemical processing. The advantages demonstrated include superior energy saving by reducing friction, exceptional corrosion resistance, and enhanced mechanical protection against abrasion and impact.

Technical Specifications and Performance Parameters

The performance of an `[anti corrosion pipe]` is defined by a range of technical specifications, ensuring suitability for its intended application. These parameters are crucial for engineers designing piping systems in harsh environments.

Key Specifications for 3LPE/3LPP/FBE Coated Pipes

| Parameter | FBE Coating | 3LPE Coating | 3LPP Coating |

|---|---|---|---|

| Operating Temperature Range | -40°C to +80°C | -40°C to +80°C | -20°C to +110°C |

| Coating Thickness (min) | 300 - 500 microns | 2.5 - 3.7 mm (for DN > 200mm) | 2.7 - 4.1 mm (for DN > 200mm) |

| Adhesion Strength (after immersion) | >12 N/mm (ASTM D3359) | >35 N/cm (ISO 21809-1) | >35 N/cm (ISO 21809-1) |

| Cathodic Disbondment (28 days @ 23°C) | <5 mm radius (ASTM G8) | <7 mm radius (ISO 21809-1) | <7 mm radius (ISO 21809-1) |

| Impact Resistance (15J) | No holidays (ASTM G14) | No holidays (ISO 21809-1) | No holidays (ISO 21809-1) |

| Flexibility (0.5°/PD) | No cracks (ASTM D522) | No cracks (ISO 21809-1) | No cracks (ISO 21809-1) |

These specifications are typically governed by international standards such as ISO 21809, NACE SP0394, DIN 30670, and CSA Z245.21. Compliance with these standards ensures reliability and interchangeability of coated pipes across global projects. The selection of the appropriate coating depends heavily on the operational temperature, mechanical stress, and chemical environment of the pipeline system.

Application Scenarios and Industry Use Cases

The versatility and robust protection offered by `[anti corrosion pipe]` systems make them indispensable across a multitude of industries and demanding application scenarios. Their ability to withstand aggressive environments ensures the safe and efficient transport of various media.

Oil and Gas Industry (Onshore & Offshore)

In the oil and gas sector, pipelines traverse vast distances, often through corrosive soils, swamps, and marine environments. 3LPE and FBE coatings are extensively used for crude oil, natural gas, and refined product pipelines. For instance, deep-sea pipelines require coatings with exceptional hydrostatic collapse resistance and long-term stability under high pressure and low temperatures. 3LPP coatings are preferred for high-temperature gas transmission lines in desert regions where pipe surface temperatures can exceed 80°C.

Water and Wastewater Treatment

Potable water distribution networks and wastewater collection systems rely on `[anti corrosion pipe]` to prevent contamination, maintain water quality, and ensure structural integrity against microbiologically influenced corrosion (MIC) and aggressive soil conditions. Epoxy-lined pipes are common for interior surfaces to prevent tuberculation and maintain flow efficiency, while external 3LPE provides robust protection against external soil corrosion.

Chemical and Petrochemical Plants

Pipelines transporting corrosive chemicals, acids, and alkalis within chemical processing plants demand specialized coatings. FBE offers excellent chemical resistance, while 3LPP can provide enhanced protection against higher temperatures and chemical concentrations, crucial for safety and operational continuity.

Mining and Slurry Transport

Mining operations involve abrasive slurries and corrosive groundwater. Coatings must withstand both erosion and corrosion. Thick 3LPE coatings provide the necessary mechanical protection against abrasive wear, coupled with excellent chemical resistance to acidic or alkaline mine water.

Utilities and Infrastructure

District heating and cooling lines, electrical conduit protection, and general industrial piping all benefit from these advanced coatings, offering extended service life and reduced maintenance in complex urban and industrial environments. Even `[anti corrosion paint for copper pipe]` used in specific HVAC or plumbing systems highlights the broader demand for corrosion protection beyond steel.

Technical Advantages and Performance Benefits

Investing in high-quality `[anti corrosion pipe]` solutions yields significant long-term technical and economic advantages for industrial projects.

Superior Corrosion Resistance

- Chemical Inertness: Polyethylene and polypropylene polymers are highly resistant to a wide range of acids, alkalis, salts, and organic solvents, preventing chemical attack on the pipe substrate.

- Moisture Barrier: The multi-layer structure, particularly of 3LPE/3LPP, provides an excellent barrier against moisture ingress, which is a primary driver of corrosion.

- Cathodic Disbondment Resistance: These coatings maintain their adhesion even under cathodic protection, preventing corrosion from occurring at coating defects.

Enhanced Mechanical Protection

- Abrasion Resistance: The outer layer of PE/PP offers high resistance to abrasion from soil, rocks, and backfill material during installation and throughout the pipeline's operational life.

- Impact Resistance: Thick polymer layers provide robust protection against mechanical damage from accidental impacts during handling, transportation, and installation. This reduces the risk of holidays (coating defects) that could expose the steel to corrosion.

- Flexibility: Engineered coatings maintain flexibility, accommodating pipe movements due to soil settlement, seismic activity, or thermal expansion/contraction without cracking.

Longevity and Cost Efficiency

- Extended Service Life: With proper application and quality control, these coatings ensure a service life of 30-50 years or more, significantly outperforming unprotected or conventionally coated pipes.

- Reduced Maintenance: The extended life cycle translates directly into reduced maintenance costs, fewer repairs, and minimized downtime, leading to substantial operational savings.

- Environmental Protection: By preventing leaks and ruptures, these systems safeguard the environment from hazardous material spills, avoiding costly cleanup and regulatory penalties.

- Energy Efficiency: Smooth internal surfaces (if internally coated) and corrosion-free exteriors maintain flow efficiency, reducing pumping energy requirements.

Vendor Comparison: Selecting the Right 3LPE Coating Suppliers

Choosing the right `[3lpe coating suppliers]` is a critical decision that impacts project success, longevity, and overall cost-effectiveness. A thorough evaluation process considering several key criteria is essential.

Key Criteria for Vendor Evaluation

| Criterion | Description & Importance |

|---|---|

| Certifications & Standards Compliance | Ensure the vendor's products and processes comply with international standards (ISO 9001, ISO 14001, OHSAS 18001, API, AWWA, ASTM, DIN, CSA, NACE, etc.). This guarantees consistent quality and adherence to industry best practices. |

| Experience & Track Record | Assess the vendor's years in business, project portfolio, and experience with similar-scale projects. Request references and case studies. Long-standing reputable vendors often indicate reliability. |

| Manufacturing Capabilities | Evaluate the production capacity, technology utilized (e.g., modern extrusion lines, advanced blast cleaning), and internal quality control procedures. Ability to handle various pipe diameters and lengths is crucial for large projects. |

| Quality Control & Testing | Inquire about their in-house testing facilities (adhesion, cathodic disbondment, impact, flexibility, holiday detection) and external third-party certifications. Comprehensive testing ensures product integrity. |

| Customization & Technical Support | Determine if the vendor can offer tailored solutions for unique project requirements (e.g., specific coating thicknesses, blend compositions). Strong technical support and engineering assistance are invaluable. |

| Logistics & Lead Time | Assess their logistical capabilities for timely delivery, especially for large volumes or international shipping. Reliable lead times are critical for project scheduling. |

| Pricing & Value Proposition | While price is a factor, prioritize value – balancing cost with quality, performance, and long-term reliability. A cheaper initial cost can lead to higher lifecycle costs if quality is compromised. |

| Warranty & After-Sales Service | Understand the warranty terms for their products and the level of after-sales support provided. This includes troubleshooting, installation guidance, and addressing potential issues. |

A comprehensive comparison based on these factors will enable informed decision-making, ensuring that the chosen supplier delivers `[anti corrosion pipe]` solutions that meet stringent project demands and deliver long-term value.

Customized Solutions for Unique Project Demands

Recognizing that no two industrial projects are identical, leading `[anti corrosion pipe]` manufacturers offer extensive customization options to precisely match specific operational and environmental requirements. This tailored approach ensures optimal performance and cost-effectiveness.

Tailoring Coating Systems

- Coating Thickness Optimization: For environments with extreme abrasion or impact risks, coating thickness can be adjusted beyond standard specifications. Conversely, for less aggressive environments, a thinner, cost-optimized coating might be suitable.

- Material Blends: The polymeric components (PE/PP) can be blended with specific additives to enhance UV resistance, increase operating temperature limits, or improve flexibility for specific bending requirements during installation.

- Dual-Layer FBE: For enhanced adhesion and cathodic disbondment resistance, a dual-layer FBE system can be applied, offering a primary anticorrosive barrier and a tougher outer FBE layer.

- Internal Coatings: For transport of corrosive media or to improve flow efficiency, internal epoxy or liquid polyurethane coatings can be applied in conjunction with external `[anti corrosion pipe]` systems.

Project-Specific Engineering and Support

- Pipe Size and Length Flexibility: Manufacturers can coat pipes ranging from small diameters (e.g., 20mm) to very large diameters (e.g., 1422mm) and in custom lengths, reducing the need for field joints.

- Field Joint Coating Solutions: Beyond factory coatings, suppliers often provide complementary field joint coating materials and application guidance to ensure continuous protection across welded joints.

- Logistical Solutions: Tailored packaging, handling, and transportation plans are developed to protect coated pipes during transit to remote or challenging project sites.

- Consultation and Design Assistance: Experienced suppliers offer engineering consultation, assisting clients in selecting the most appropriate coating system based on detailed project parameters, environmental assessments, and budget constraints.

The ability to provide highly customized and project-specific solutions is a hallmark of an authoritative and experienced `[anti corrosion pipe]` provider, ensuring that clients receive the most effective and efficient protection for their critical infrastructure investments.

Application Case Studies & Customer Feedback

Real-world application demonstrates the tangible benefits of advanced `[anti corrosion pipe]` solutions. Here are examples showcasing their effectiveness and highlighting client satisfaction.

Case Study 1: Major Offshore Oil & Gas Pipeline

Client: Leading International Energy Company

Project: Subsea Gas Transmission Pipeline (300 km, DN 900)

Challenge: Extreme deep-water environment, high pressures, low temperatures, and aggressive marine corrosion. Required a coating with superior mechanical protection and high cathodic disbondment resistance.

Solution: Application of a customized 3LPP coating system designed for deep-water applications, coupled with concrete weight coating. Strict adherence to ISO 21809-1 and DNVGL-ST-F101 standards.

Outcome: Project successfully installed with zero coating damage reported during laying. Post-installation surveys after 5 years indicated pristine coating integrity, significantly extending the projected lifespan of the pipeline and minimizing intervention costs. The client praised the robust performance and the extensive technical support provided throughout the project lifecycle.

Case Study 2: Municipal Water Supply Infrastructure Upgrade

Client: Large Metropolitan Water Utility

Project: Replacement of aging potable water mains (50 km, DN 600-DN 1000) in highly corrosive urban soil.

Challenge: Corrosive soil conditions (high acidity, varying moisture), demanding installation timeline, and a requirement for internal coating to maintain water purity and flow.

Solution: Externally coated pipes with 3LPE (DIN 30670) for optimal soil corrosion protection, combined with internal liquid epoxy lining (AWWA C210) for potable water contact. All pipes underwent 100% holiday detection and adhesion testing.

Outcome: The project was completed on schedule, and the robust `[anti corrosion pipe]` system has ensured consistent water quality and zero external corrosion issues over 10 years of operation. The client specifically highlighted the ease of installation due to the factory-applied coatings and the excellent project management.

Frequently Asked Questions (FAQ)

- Q1: What is the primary difference between 3LPE and 3LPP coatings?

- A1: The main difference lies in the outer polymer layer. 3LPE (3-Layer Polyethylene) uses polyethylene and is suitable for operating temperatures up to 80°C. 3LPP (3-Layer Polypropylene) uses polypropylene, offering superior temperature resistance, typically up to 110°C, making it ideal for high-temperature applications.

- Q2: How does FBE compare to 3LPE in terms of protection?

- A2: FBE (Fusion Bonded Epoxy) provides excellent corrosion protection, superior adhesion, and good cathodic disbondment resistance. However, it offers less mechanical protection against impact and abrasion compared to the thick outer layer of polyethylene or polypropylene in 3LPE/3LPP systems. 3LPE combines the benefits of FBE's adhesion with the mechanical robustness of PE.

- Q3: What testing standards should I look for when specifying anti-corrosion pipe?

- A3: Key international standards include ISO 21809 series (for external coatings for buried or submerged pipelines), DIN 30670 (for PE coatings), CSA Z245.21 (for external polyethylene coatings), NACE SP0394 (for FBE), and ASTM standards (e.g., ASTM G8 for cathodic disbondment, ASTM D3359 for adhesion).

- Q4: Can these anti-corrosion coatings be applied to fittings and bends?

- A4: Yes, specialized coating facilities are equipped to apply these coatings to various pipe fittings, elbows, and bends, ensuring comprehensive protection across the entire piping system. Specific application methods like powder coating or heat-shrinkable sleeves are often used for complex geometries or field joints.

- Q5: What is the typical lead time for an anti-corrosion pipe order?

- A5: Lead times vary significantly based on pipe size, quantity, coating type, and current production schedules. Generally, for standard orders, lead times can range from 4 to 12 weeks. Large or highly customized orders may require longer. We recommend contacting our sales team with your specific requirements for an accurate estimate.

Lead Time, Warranty, and Customer Support

Our commitment extends beyond delivering high-quality `[anti corrosion pipe]` solutions; we prioritize transparent lead times, robust warranty policies, and unparalleled customer support to ensure your project's success and peace of mind.

Lead Time & Fulfillment

We understand the critical nature of project timelines. Our advanced manufacturing capabilities and streamlined logistics enable us to provide competitive lead times. Upon receipt of a confirmed order and specifications, we typically aim for a production and coating period of 4-8 weeks for standard sizes and coating types. For larger projects or highly specialized requirements, lead times will be confirmed during the quotation phase, with dedicated project managers overseeing the entire fulfillment process to ensure on-time delivery.

Warranty Commitments

We stand by the quality and performance of our anti-corrosion pipe products. All our coated pipes are backed by a comprehensive warranty, typically for a period of [e.g., 10 to 15 years] from the date of shipment, guaranteeing the coating against manufacturing defects and premature failure under specified operating conditions. Full warranty details and terms and conditions are provided with every quotation and order confirmation.

Dedicated Customer Support

Our commitment to our clients extends throughout the product lifecycle. Our expert customer support team is available to assist with:

- Technical inquiries and coating selection guidance.

- Order status updates and logistical coordination.

- Post-sales support, including installation advice and troubleshooting.

- Assistance with documentation and certification requirements.

We are dedicated to building long-term partnerships by providing responsive, knowledgeable, and reliable support for all your anti-corrosion piping needs.

References

- ISO 21809-1: Petroleum and natural gas industries — External coatings for buried or submerged pipelines used in pipeline transportation systems — Part 1: Polyolefin coatings (3-layer PE and 3-layer PP). International Organization for Standardization, 2018.

- NACE SP0394-2019: Application, Performance, and Quality Control of Plant-Applied, Fusion-Bonded Epoxy (FBE) External Pipe Coating. NACE International, 2019.

- ASTM G8: Standard Test Methods for Cathodic Disbonding of Pipeline Coatings. ASTM International, 2021.

- DIN 30670: Polyethylene coatings for steel pipes and fittings — Requirements and testing. Deutsches Institut für Normung, 2012.

- DNVGL-ST-F101: Submarine Pipeline Systems. DNV GL, 2021.

Post time: Sep . 09, 2025 23:20