Bulk Galvanized Pipe: an insider’s field notes from 2025

If you’re sourcing Bulk Galvanized Pipe this year, you’ve probably noticed two things: zinc prices wobble, and delivery windows matter more than ever. In fact, buyers I talk to want what works in the real world—clean welds, consistent zinc weight, honest test data.

What’s moving the market

Infrastructure upgrades, farm irrigation retrofits, and a surprisingly strong push in solar racking have kept demand steady. Coastal projects are switching back to hot-dip after some powder-coated experiments didn’t age well. To be honest, durability talks—especially where maintenance crews are stretched thin.

Core specs (quick glance)

| Parameter | Typical Range |

|---|---|

| Outside Diameter | 1/2”–32” |

| Wall Thickness | 2.77 mm—33 mm |

| Length | 5.8 m–12 m (custom cut ≈ possible) |

| Steel Grades | Q195/Q215/Q235/Q345/10#/20#/ASTM A106 Gr.B |

| Standards | GB, ANSI, ASME/ASMRE, ASTM, JIS, DIN, BS, EN |

| Zinc Coating | 170–550 g/㎡ (≈ 24–78 μm; real-world may vary) |

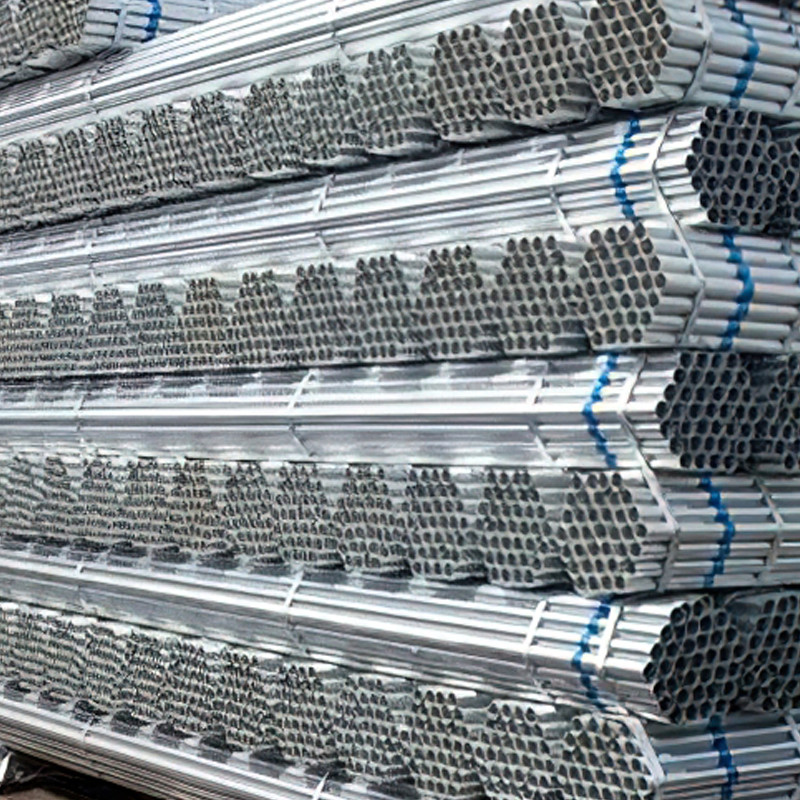

| Packaging | Plastic caps, bundled |

Process flow that actually holds up

Materials: low-carbon and mild steels (Q195–Q345; A106 Gr.B where needed) chosen for weldability and toughness.

Methods: hot-dip galvanizing after fabrication—degrease, pickle, flux, immerse in molten zinc ≈ 450°C, quench, passivate. Threaded ends or plain ends per order.

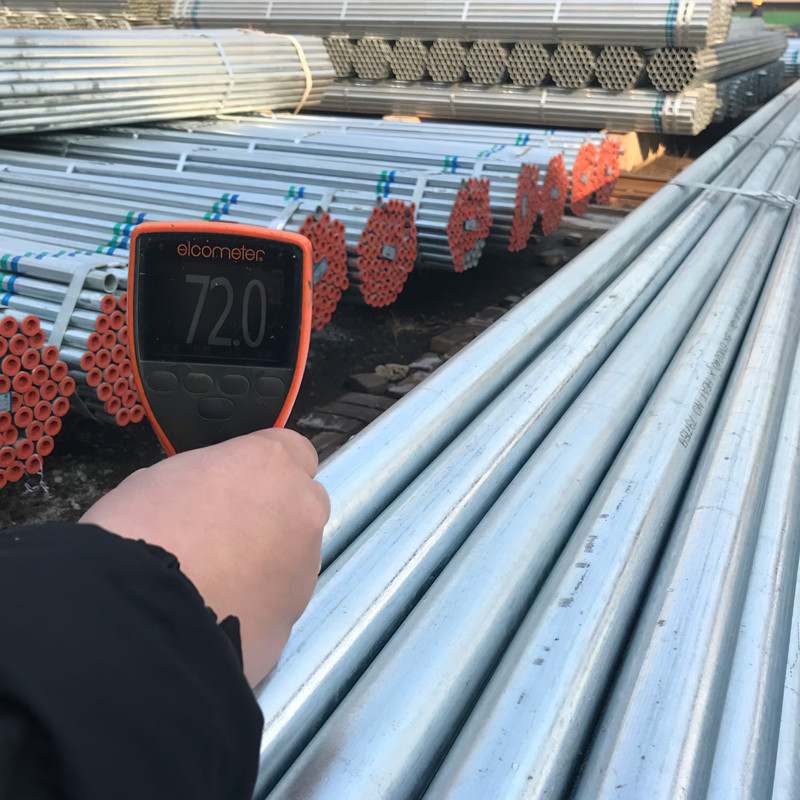

Testing & standards: coating mass per ISO 1461 / ASTM A123; adhesion checked via bend/impact; salt spray reference ASTM B117 for comparative endurance; dimensional per ASTM A53/A106 or EN 10240. Typical service life: inland 25–50 years, industrial/coastal 10–25 (environment-dependent).

Applications (where it pays off)

- Water lines and municipal framing (EN/BS specs on request)

- Scaffolding and guard rails—contractors like the robust spangle

- Ag irrigation, greenhouses, and fencing—many customers say the coating cleans easily

- HVAC supports, cable trays, and solar racking (corrosion credit matters)

- Fire protection piping where allowed by local code

Bulk Galvanized Pipe advantages: low lifetime maintenance, predictable coating mass, and good availability in 5.8 m export-friendly lengths. Actually, the zinc consistency is what inspectors often notice first.

Vendor snapshot (realistic expectations)

| Supplier | Origin | Zinc g/㎡ | Certs | Lead Time | Notes |

|---|---|---|---|---|---|

| World Steel Material | Rm 1103, Shangpintaihu Bld 3#, Tongzhou, Beijing | 170–550 | ISO 9001, EN/ASTM compliance | ≈ 10–25 days | Strong customization, steady QC data |

| Regional Trader A | Mixed | ≈ 120–275 | ISO (claimed) | 20–40 days | Check MTRs; coating variance reported |

| Local Mill B | Domestic | 200–400 | CE, ISO | 7–21 days | Good for short runs; MOQ flexible |

Customization and QC notes

Options: OD 1/2”–32”, wall 2.77–33 mm, plain/threaded ends, NPT/BSP, beveled or square ends, heavier zinc target (ask for ≥ 350 g/㎡), custom lengths, logo stenciling, seaworthy packaging.

Recent lot data (sample): Zn mass 320–360 g/㎡, thickness 45–55 μm (mag gauge), adhesion pass (180° bend), salt spray 480 h reference with minor white rust only.

Mini case files

Coastal marina: upgraded handrails and service lines; after 18 months, inspectors reported uniform dull gray patina, zero red rust at cuts (proper cold-galv touch-up helped).

Ag irrigation coop: switched to Bulk Galvanized Pipe with 350 g/㎡ spec; downtime dropped—farm manager said the bundles arrived “square and weld-ready,” which sounds small but saves hours.

Bottom line: if your workload lives outdoors or near brine, Bulk Galvanized Pipe keeps budgets sane. Verify coating targets, insist on MTRs and galvanizing certificates, and—this is key—align standards with your AHJ before the PO.

Authoritative citations

Post time: Oct . 23, 2025 17:50