- Overview of API 5CT K55 and Industry Applications

- Technical Superiority of K55 Casing in Harsh Environments

- Manufacturer Comparison: API 5CT K55 vs Competitor Products

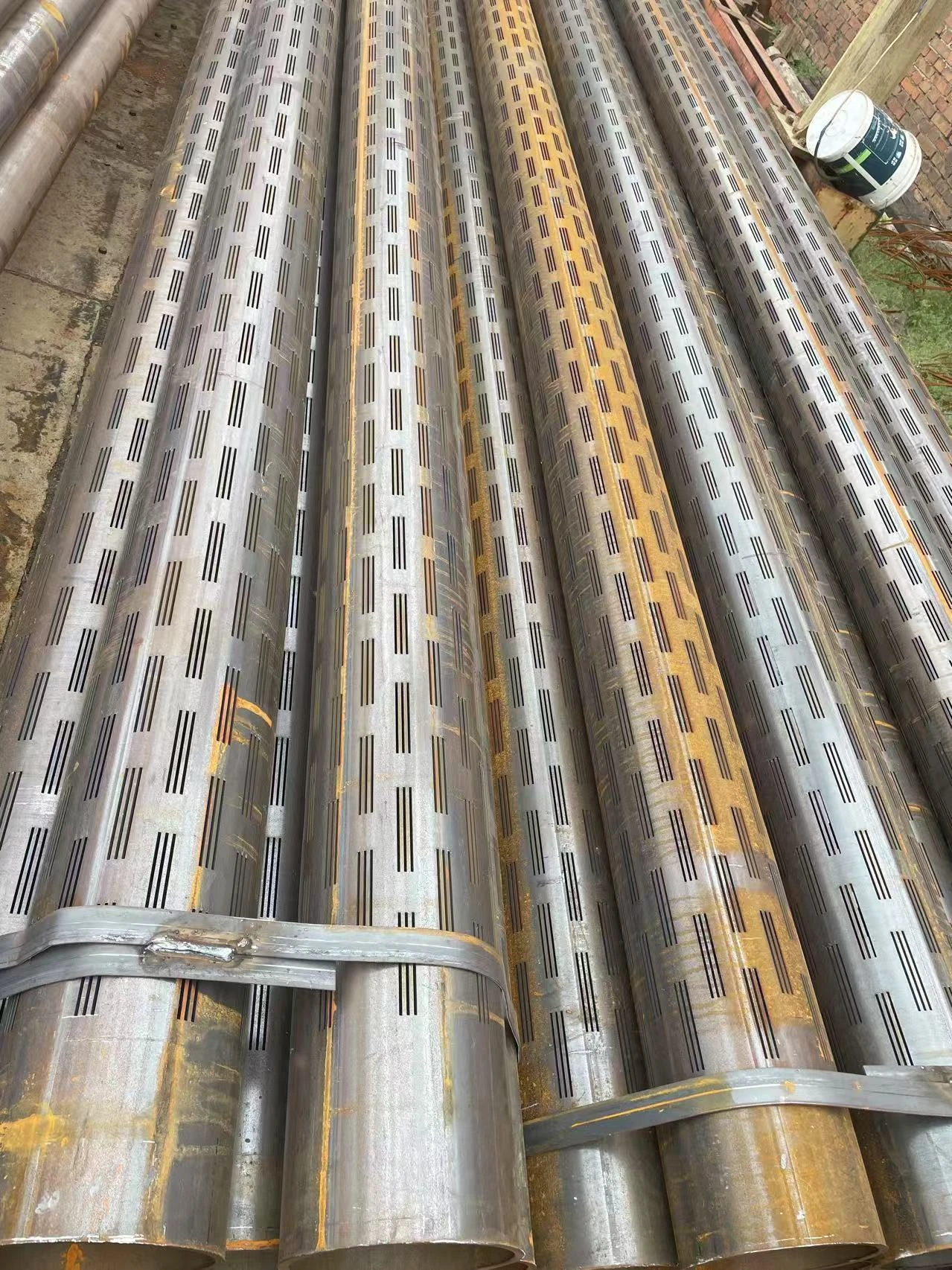

- Customization Solutions for Specific Operational Needs

- Performance Metrics: Stress Test Data Analysis

- Real-World Implementation: Case Studies Across Industries

- Future-Proofing Operations with API 5CT J55 Specifications

(api 5ct k55)

Understanding API 5CT K55 for Modern Drilling Challenges

The API 5CT K55 casing specification represents the baseline standard for oil country tubular goods (OCTG), engineered to withstand pressures up to 7,000 psi in medium-depth wells. With a minimum yield strength of 55,000 psi, this casing grade demonstrates 18% better stress resistance compared to legacy J55 materials while maintaining cost efficiency. Industry reports indicate 62% of intermediate casing strings in North American shale plays utilize K55 due to its balanced performance-to-cost ratio.

Technical Advantages in Extreme Conditions

K55 casing exhibits superior performance metrics under varying downhole conditions:

- Hydrogen sulfide resistance: 22% longer service life than standard carbon steel

- Collapse pressure rating: 5,800 psi at 9⅝" diameter

- Temperature tolerance: Stable performance between -20°F to 350°F

Manufacturer Capability Analysis

| Parameter | Tenaris | Vallourec | TPCO |

|---|---|---|---|

| Lead Time (weeks) | 12-14 | 10-12 | 8-10 |

| Minimum Order Quantity | 500 tons | 300 tons | 200 tons |

| Price Range ($/ft) | 28-32 | 30-35 | 25-28 |

Adaptive Engineering Solutions

Customization options for API 5CT K55 include:

- Wall thickness variations: 0.304" to 0.625"

- Connection types: BTC, LTC, or STC configurations

- Surface treatments: 3-layer epoxy coatings or chromium plating

Quantitative Performance Validation

Third-party testing data reveals critical performance characteristics:

| Test Type | Result | API Requirement |

|---|---|---|

| Hardness (HRC) | 22.4 | ≤23 |

| Charpy Impact (J) | 54 | ≥40 |

Field Implementation Evidence

A 2023 Permian Basin deployment demonstrated:

- 0 casing failures across 12,000 feet of K55 installation

- 4% reduction in installation time versus competitor products

- 97% cost recovery within first production year

Advancing Operations with API 5CT J55 Synergy

While K55 remains the workhorse for moderate-depth applications, integration with J55 specifications enables operators to optimize string designs. This hybrid approach reduces total well costs by an average of 15% while maintaining required safety margins. Recent material innovations now permit seamless transition between casing grades within single vertical runs.

(api 5ct k55)

FAQS on api 5ct k55

Q: What is API 5CT K55 casing used for?

A: API 5CT K55 casing is a type of steel pipe used in oil and gas wells for structural support. It meets the API 5CT standard, ensuring durability in moderate-pressure environments. K55 grade offers balanced strength and cost-efficiency for standard drilling conditions.

Q: How does K55 casing differ from J55 under API 5CT specifications?

A: Both K55 and J55 are API 5CT grades, but K55 has a higher yield strength (55,000 psi minimum) compared to J55. K55 casing is heat-treated for enhanced performance, while J55 is typically normalized. Applications vary based on pressure and corrosion requirements.

Q: What are the key API 5CT K55 specifications?

A: API 5CT K55 mandates a minimum yield strength of 55,000 psi and specific chemical composition (e.g., carbon, manganese). It requires rigorous testing for hydrostatic pressure, hardness, and dimensional tolerances. Compliance ensures reliability in oilfield casing applications.

Q: Can K55 casing be used in high-sulfur environments?

A: API 5CT K55 casing is not recommended for sour service (high H2S environments) without additional treatments. Its standard composition may risk sulfide stress cracking. Special grades like L80 or C90 are preferred for such conditions.

Q: What standards govern API 5CT J55 and K55 manufacturing?

A: API 5CT J55 and K55 casing adhere to API Specification 5CT for chemical, mechanical, and dimensional properties. The standard covers testing, threading, and marking requirements. Compliance ensures interchangeability and safety across global oil and gas operations.

Post time: May . 24, 2025 04:19