Unlocking Global Opportunities: CIMIE and the Future of Industrial Pipe Fittings

The China (Beijing) International Metallurgical Industry Expo (CIMIE) stands as a pivotal event, a global stage where the titans of the steel and metallurgical industries converge to showcase innovation, forge partnerships, and chart the course for future development. For B2B decision-makers deeply invested in the robust growth of infrastructure, manufacturing, and energy sectors, CIMIE is more than an exhibition—it's a barometer for industry trends and a gateway to cutting-edge solutions.

At the heart of this dynamic expo, exhibitors like Beijing Sinoworld Steel Material Co., Ltd. emerge as key global suppliers of quality steel materials and advanced processing machinery. Their presence, among others, underscores China's indispensable role in the global supply chain, particularly for the intricate and demanding industrial pipe fittings manufacturing industry. This sector, critical for everything from oil and gas pipelines to urban water infrastructure and advanced industrial systems, constantly seeks higher performance, greater efficiency, and unparalleled reliability. CIMIE provides the ideal platform to discover the advancements driving these essential components.

Industry Trend Spotlight: Navigating the Evolving Steel Landscape

The global steel market is currently experiencing a transformative period, marked by a confluence of evolving demands and technological breakthroughs. The push for high-strength, lightweight steel is no longer a niche request but a universal necessity, driven by infrastructure projects that demand durability without excessive weight, and automotive applications striving for enhanced fuel efficiency and safety.

- Green Steel and Low-Carbon Production: A paramount trend is the rapid expansion of green steel and low-carbon production methods. As environmental regulations tighten and corporate sustainability goals become more ambitious, the demand for steel produced with a significantly reduced carbon footprint is surging. This impacts everything from raw material sourcing to manufacturing processes for industrial pipe fittings, pushing manufacturers to innovate.

- Specialized Alloys: The growth in specialized alloys is another critical area. Industries such as renewable energy (wind turbines, solar panel frames) and advanced manufacturing (aerospace, medical devices) require materials with specific properties—corrosion resistance, extreme temperature tolerance, or unique strength-to-weight ratios. This specialized demand extends directly to the production of high-performance pipe fittings that must withstand rigorous operational environments.

- Customized Steel Solutions: The era of one-size-fits-all is fading. Complex projects now demand highly customized steel solutions, requiring manufacturers to offer tailored specifications and bespoke designs for industrial pipe components. This shift necessitates flexible and advanced manufacturing capabilities.

Market data reinforces these trends: The global steel market is expected to see steady growth, primarily fueled by sustained infrastructure development in emerging economies, the ambitious expansion of renewable energy projects worldwide, and a robust rebound in key manufacturing sectors. However, this growth is not without its challenges. The industry grapples with volatile raw material prices, increasingly stringent environmental regulations, and ongoing trade protectionism. These factors collectively compel companies to prioritize more sustainable, efficient, and technologically advanced production methods to maintain competitiveness and profitability.

Emerging focus areas for the steel and industrial pipe fittings industry include:

- Green Steel Technologies: Innovations in hydrogen-based steelmaking and carbon capture technologies.

- High-Performance Alloys: Development of new materials with enhanced properties for extreme applications.

- Smart Manufacturing Solutions: Integration of AI, IoT, and automation for optimized production processes.

- International Trade Dynamics: Navigating complex global trade policies and fostering resilient supply chains.

These shifts collectively highlight a compelling need for advanced machinery and precision manufacturing in the industrial pipe fittings sector, making CIMIE a critical event for identifying partners equipped to meet these evolving demands.

Profiles of Leading Innovators in Industrial Steel and Machinery

Beijing Sinoworld Steel Material Co., Ltd.

Positioned at the forefront of China's metallurgical expertise, Beijing Sinoworld Steel Material Co., Ltd. exemplifies the nation's ambition in the global steel market. The very name "Sinoworld" and its associated domain, world-steelmaterial.com, clearly articulate a strategic vision extending far beyond domestic borders.

Strategically located in Beijing, the company benefits immensely from access to China's vast domestic market and an incredibly robust supply chain infrastructure. This strategic positioning allows Sinoworld to source premium raw materials efficiently and to distribute its diverse range of steel materials and machinery with unparalleled logistical advantages. While the company offers a broad spectrum of steel products for various industrial applications, its specialized focus on machinery for industrial pipe fittings manufacturing truly sets it apart.

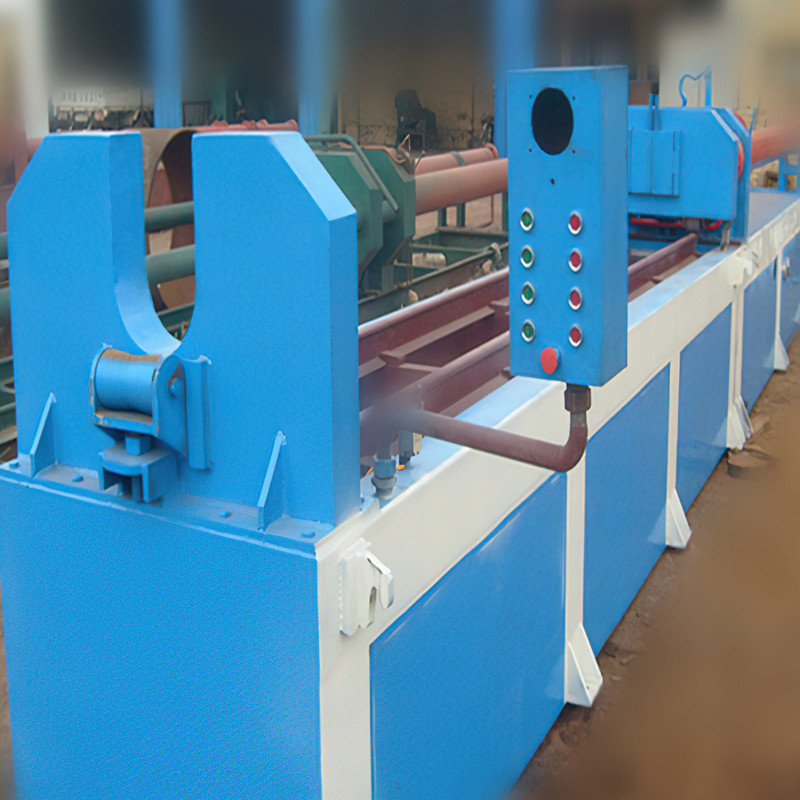

Beijing Sinoworld Steel Material Co., Ltd. is a key player in equipping manufacturers with the tools to produce high-quality industrial pipe fittings. Their core offerings, the hot forming elbow machine and the hydraulic pipe fittings machine, are instrumental in achieving the precision, strength, and consistency required in modern pipe fitting production. These advanced machines are designed to meet the rigorous demands of sectors like oil & gas, petrochemicals, power generation, and construction, where component integrity is non-negotiable.

The hot forming elbow machine utilizes high-temperature forming processes to create seamless, high-integrity elbows, ensuring uniform wall thickness and structural soundness crucial for critical applications. The hydraulic pipe fittings machine, on the other hand, excels in precision shaping and sizing, allowing for the efficient production of a variety of fittings with complex geometries. These machines are not just about manufacturing; they are about enabling clients to produce fittings that meet stringent international standards, thereby enhancing project safety and longevity.

Their dedication to innovation and quality makes Beijing Sinoworld Steel Material Co., Ltd. a vital partner for any enterprise looking to enhance its industrial pipe fittings manufacturing capabilities. Learn more about their advanced solutions at world-steelmaterial.com/hot-forming-elbow-machine.html.

Other Leading Chinese Steel Giants

Beyond specialized machinery, CIMIE also highlights the comprehensive strength of China's primary steel producers, whose massive output and technological advancements underpin industries worldwide.

- China Baowu Steel Group Corporation Limited (Baowu Steel): The world's largest steel producer, Baowu Steel is a titan known for its vast production capacity and commitment to advanced materials, including high-end steel for automotive, shipbuilding, and energy sectors. Their strategic investments in green steel technologies are setting new industry benchmarks.

- HBIS Group Co., Ltd.: A prominent global steelmaker, HBIS is recognized for its comprehensive product range, from construction steel to specialized alloys. They are actively expanding their international presence and focusing on intelligent manufacturing and environmental protection.

- Anshan Iron and Steel Group Corporation (Ansteel Group): A historical cornerstone of China's steel industry, Ansteel boasts a rich legacy and continues to be a major producer of high-quality steel products, including plates, sections, and wire rods, serving diverse heavy industries.

- Shougang Group Co., Ltd.: Evolving from a traditional iron and steel enterprise, Shougang has diversified into urban complex operations, high-tech industries, and financial services, while maintaining its strong metallurgical core, especially in high-strength automotive steel.

Market Outlook & Opportunities: Charting the Future of Industrial Pipe Fittings

The trajectory of the industrial pipe fittings market is undeniably upward, driven by global urbanization, the energy transition, and the continuous need for infrastructure upgrades. Upcoming trends indicate a sustained demand for more resilient, corrosion-resistant, and pressure-withstanding pipe fittings, especially as projects delve into more challenging environments, such as deep-sea oil extraction or high-temperature industrial processes.

Buyer demand is shifting towards comprehensive solutions that offer not only superior material quality but also verifiable sustainability credentials and efficient manufacturing lead times. This puts a premium on manufacturers who can leverage advanced technologies. Key opportunities are emerging in several areas:

- Automation in Production: The integration of robotics and automated systems in the pipe fittings manufacturing process is critical for reducing labor costs, increasing production speed, and, most importantly, enhancing precision and consistency. Machines like the hot forming elbow machine and hydraulic pipe fittings machine are foundational to achieving this level of automation, ensuring repeatable quality and higher throughput.

- Smart Manufacturing Solutions: Beyond automation, the adoption of Industry 4.0 principles – including IoT sensors, data analytics, and AI-driven predictive maintenance – is transforming factories into smart plants. This allows for real-time monitoring, optimized energy consumption, and proactive issue resolution, making production of industrial pipe fittings far more efficient and less prone to costly downtime.

- Sustainability and Lifecycle Management: The entire lifecycle of steel products, from raw material extraction to end-of-life recycling, is under scrutiny. Opportunities abound for companies that can demonstrate sustainable sourcing, energy-efficient production (including machinery like those offered by Sinoworld), and the ability to produce fittings with extended service lives, reducing the need for frequent replacements.

For B2B buyers, understanding these trends means recognizing that investment in state-of-the-art machinery and partnerships with forward-thinking manufacturers is not just an option, but a strategic imperative for long-term success.

Buyer/Business Takeaways: Strategic Steps for Success

For B2B decision-makers in the industrial pipe fittings manufacturing sector, navigating the complexities of the global market requires strategic foresight and a willingness to embrace innovation. Investing in high-quality machinery for industrial pipe fittings isn't merely about acquiring equipment; it's about securing a competitive edge, ensuring product integrity, and future-proofing your operations.

Why Investing in Advanced Pipe Fittings Manufacturing Makes Sense Now:

- Meeting Rising Quality Demands: As infrastructure projects become more complex and critical, the tolerance for faulty components diminishes. Advanced machinery, such as a hot forming elbow machine, ensures consistent material properties and precise dimensions, crucial for safety and operational efficiency.

- Enhancing Operational Efficiency: Modern hydraulic pipe fittings machine systems offer higher throughput, reduced material waste, and lower energy consumption per unit, directly impacting your bottom line.

- Gaining Competitive Advantage: Companies equipped with superior manufacturing capabilities can offer better quality, faster delivery, and more customized solutions, differentiating themselves in a crowded market.

- Adhering to Sustainability Goals: Newer machines are designed with environmental efficiency in mind, helping your operations meet increasingly stringent green standards and appeal to eco-conscious clients.

Tips for Adopting or Partnering with Chinese Manufacturers:

- Due Diligence is Key: Thoroughly vet potential partners. Look for certifications (ISO, CE), robust quality control processes, and a track record of reliability. CIMIE provides an excellent opportunity for face-to-face interactions and initial assessments.

- Focus on After-Sales Support: For machinery like the hot forming elbow machine or hydraulic pipe fittings machine, comprehensive after-sales service, spare parts availability, and technical support are paramount. Clarify these details upfront.

- Clear Communication: Establish clear communication channels and ensure all specifications, expectations, and terms are documented precisely to avoid misunderstandings.

- Visit Facilities: If possible, arrange factory visits to witness production capabilities and quality assurance protocols firsthand.

Future-Proof Strategies:

- Embrace Digital Transformation: Integrate smart manufacturing and IoT into your operations. Look for machinery that can be networked and managed remotely.

- Diversify Supply Chains: While leveraging the strengths of Chinese manufacturers, consider diversifying your supply chain to mitigate geopolitical risks and ensure resilience.

- Invest in R&D: Stay ahead by investing in research and development for new materials, alloys, and advanced manufacturing techniques for industrial pipe fittings.

- Focus on Green Initiatives: Position your company as a leader in sustainable practices. This will attract clients and meet future regulatory demands.

Conclusion: Shaping Tomorrow's Industrial Landscape

The China (Beijing) International Metallurgical Industry Expo (CIMIE) is far more than an annual event; it's a critical nexus where the future of global steel and industrial manufacturing is forged. It brings into sharp focus the advancements in steel materials, the rise of green production, and the indispensable role of precision machinery in producing high-quality industrial pipe fittings.

For companies like Beijing Sinoworld Steel Material Co., Ltd., showcasing innovations such as the hot forming elbow machine and hydraulic pipe fittings machine at CIMIE underscores China's commitment to technological leadership and its capacity to meet the world's most demanding industrial needs. By attending CIMIE and engaging with leading manufacturers, B2B decision-makers gain invaluable insights and establish partnerships essential for thriving in the evolving global industrial pipe fittings market.

Ready to elevate your industrial pipe fittings manufacturing capabilities?

Visit Beijing Sinoworld Steel Material Co., Ltd. to learn more!

Post time: Sep . 24, 2025 09:35