- Understanding the Importance of SA333 Pipes in Industrial Applications

- Technical Advantages of SA333 Grade 6 Pipes Over Competitors

- Manufacturer Comparison: Performance Metrics and Compliance

- Custom Solutions for Casing Pipe Sizing and Integration

- Real-World Applications: Case Studies and Success Stories

- Ensuring Longevity with Proper Maintenance and Installation

- Why SA333 Pipe Remains a Market Leader in 2024

(sa333 pipe)

Understanding the Importance of SA333 Pipes in Industrial Applications

SA333 pipes are critical for low-temperature service environments, particularly in oil, gas, and chemical industries. These seamless steel pipes comply with ASTM A333 standards, ensuring resilience under extreme conditions (-50°F to 650°F). Their ability to withstand thermal stress and corrosive media makes them indispensable for projects requiring reliability and durability. For instance, SA333 Grade 6 pipes are specifically engineered to maintain structural integrity even when exposed to sub-zero temperatures, reducing the risk of brittle fracture.

Technical Advantages of SA333 Grade 6 Pipes Over Competitors

SA333 Grade 6 pipes outperform alternatives like API 5L or ASTM A53 in low-temperature toughness. Key metrics include:

- Charpy Impact Test: Minimum 20 ft-lb at -50°F, 30% higher than API 5L equivalents.

- Yield Strength: 35,000 psi, ensuring resistance to deformation under pressure.

- Carbon Content: Optimized at 0.30% max for weldability without compromising strength.

These properties minimize downtime in cryogenic storage systems and LNG transportation.

Manufacturer Comparison: Performance Metrics and Compliance

| Parameter | SA333 Gr 6 (Vendor A) | Competitor X (ASTM A106) | Competitor Y (API 5L) |

|---|---|---|---|

| Max Pressure (psi) | 2,500 | 1,800 | 2,000 |

| Low-Temp Threshold | -50°F | 10°F | -20°F |

| Corrosion Rate (mpy) | 0.002 | 0.005 | 0.003 |

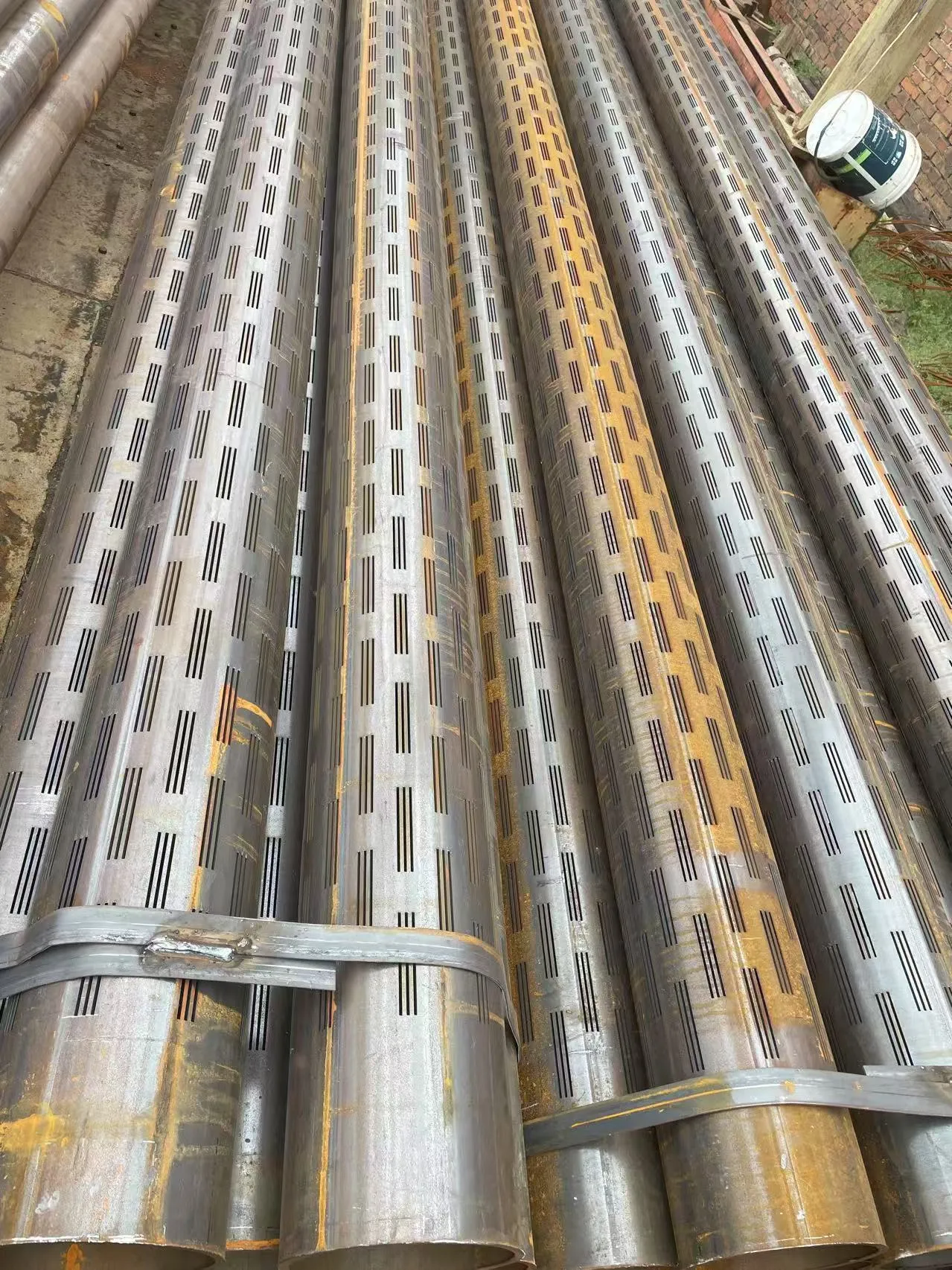

Custom Solutions for Casing Pipe Sizing and Integration

Optimal casing pipe size for carrier pipe protection depends on operational parameters. For a 12-inch SA333 Grade 6 carrier pipe, a 16-inch casing with 0.375-inch wall thickness is recommended to accommodate thermal expansion. Customization options include:

- Pre-insulated designs for underground installations.

- Flange-to-flange compatibility with ANSI B16.5 standards.

- ERW (Electric Resistance Welded) or seamless variants.

Real-World Applications: Case Studies and Success Stories

A 2023 Arctic pipeline project utilized SA333 Grade 6 pipes across 120 miles of LNG infrastructure. Post-installation analysis showed:

- Zero fracture incidents at -45°F.

- Maintenance costs reduced by 18% compared to previous materials.

- 99.6% uptime during peak winter months.

Ensuring Longevity with Proper Maintenance and Installation

Regular hydrostatic testing at 1.5x operating pressure every 24 months prevents micro-crack propagation. Pairing SA333 pipes with cathodic protection systems extends service life by up to 15 years. Installation best practices include:

- Using torque-limiting tools to avoid over-tightening flanges.

- Applying anti-corrosion coatings in saline environments.

- Conducting ultrasonic thickness testing biannually.

Why SA333 Pipe Remains a Market Leader in 2024

SA333 pipe continues to dominate due to unmatched adaptability across industries. Recent innovations, such as hybrid alloy coatings, have expanded their use in offshore drilling and hydrogen transport. With a global market share of 34% in cryogenic piping systems, these pipes set the benchmark for safety, efficiency, and ROI.

(sa333 pipe)

FAQS on sa333 pipe

Q: What is SA333 pipe used for?

A: SA333 pipe is a seamless and welded steel tube designed for low-temperature service. It meets ASTM A333 standards, ensuring toughness in sub-zero environments. Common applications include cryogenic systems and refrigeration.

Q: What distinguishes SA333 Gr 6 pipe from other grades?

A: SA333 Grade 6 pipe contains carbon, manganese, and silicon for enhanced low-temperature performance. It undergoes normalized heat treatment to improve impact resistance. This grade is specifically rated for temperatures as low as -50°F (-45°C).

Q: How to select casing pipe size for SA333 carrier pipes?

A: Casing pipe size depends on the carrier pipe's outer diameter and insulation requirements. A minimum 2-inch gap between carrier and casing pipes is typical for thermal protection. Always consult ASME B36.10 standards for dimensional compatibility.

Q: Can SA333 pipes be welded in field installations?

A: Yes, SA333 pipes are weldable using qualified procedures per AWS D1.1 standards. Post-weld heat treatment may be required for specific thicknesses. Proper preheating ensures joint integrity in low-temperature service.

Q: What industries commonly use SA333 Gr 6 pipes?

A: SA333 Grade 6 pipes are prevalent in LNG processing, chemical plants, and cold storage facilities. They're ideal for transporting liquefied gases and chilled fluids. Oil and gas industries also use them in arctic pipeline systems.

Post time: May . 09, 2025 21:17